so i went on the dyno 2 days ago

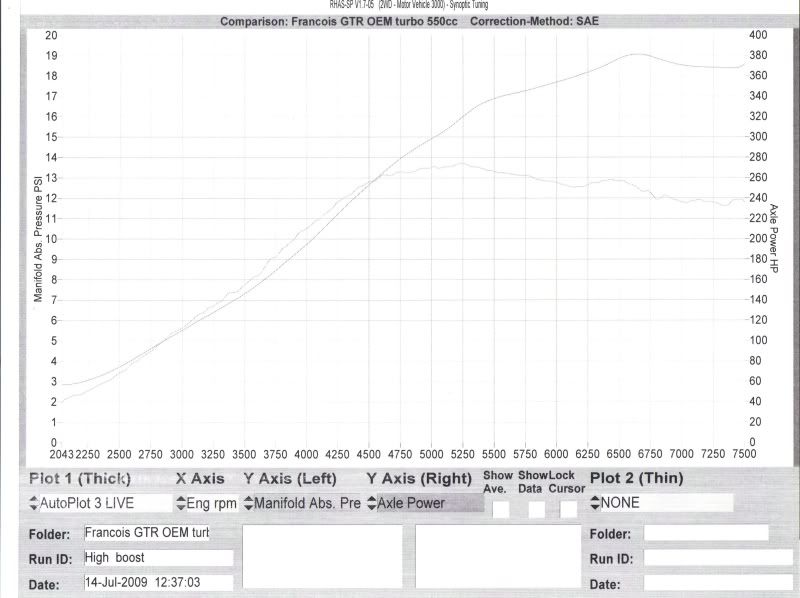

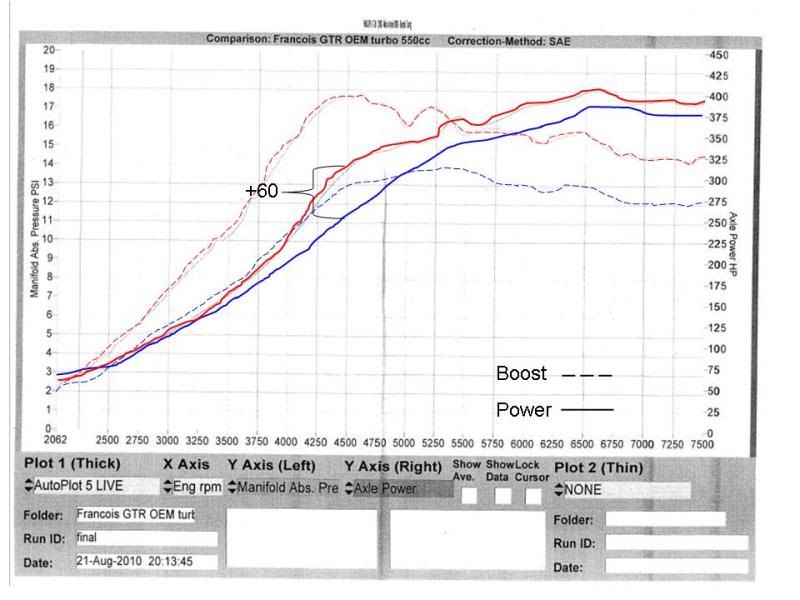

LAST YEAR, i got 382whp @ 6600rpm with 13,7psi peak boost

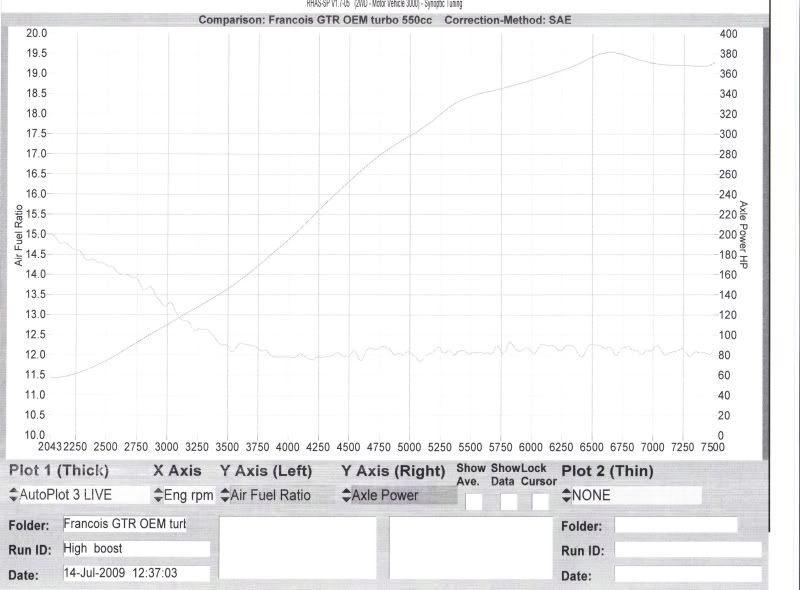

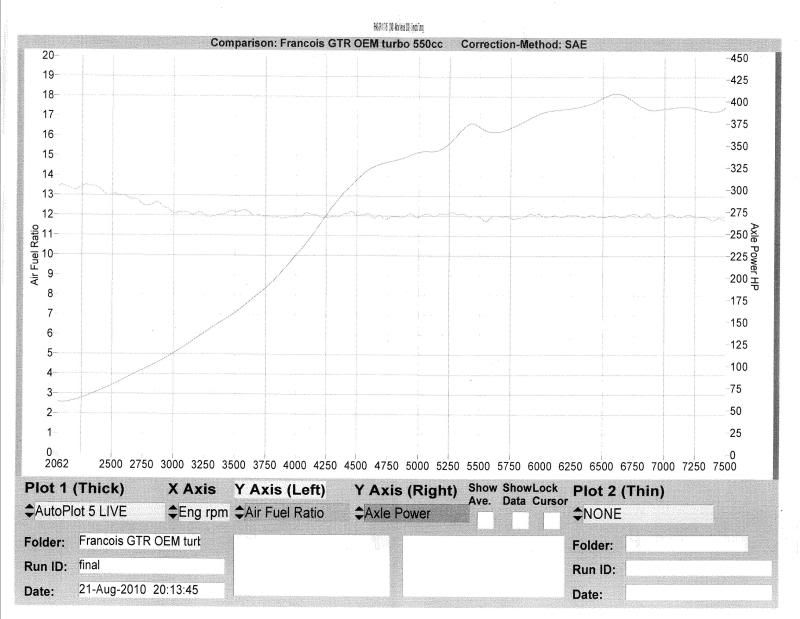

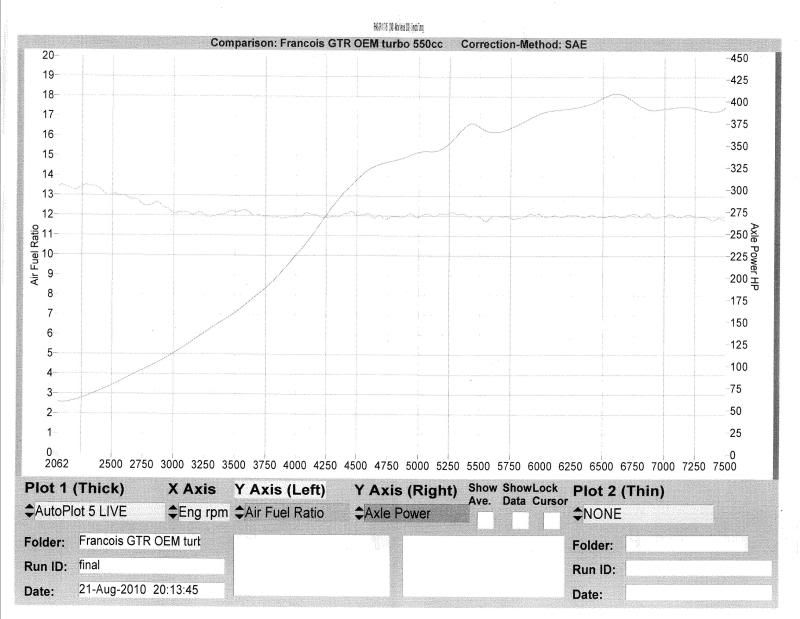

with AFRs at 12

but this year, i changed my old boost controller for a brand new HKS EVC-S, changed to brand new Splitfire Coilpacks, swapped the old recirc valves for brand new HKS SSQV BOVs and removed the cat in favor of a resonated test pipe

all those mods were to help minimize the boost drop, and make the turbos spool a bit faster

the HKS EVC-S was a pain in the ass to program and it seemed we never got what was programed,

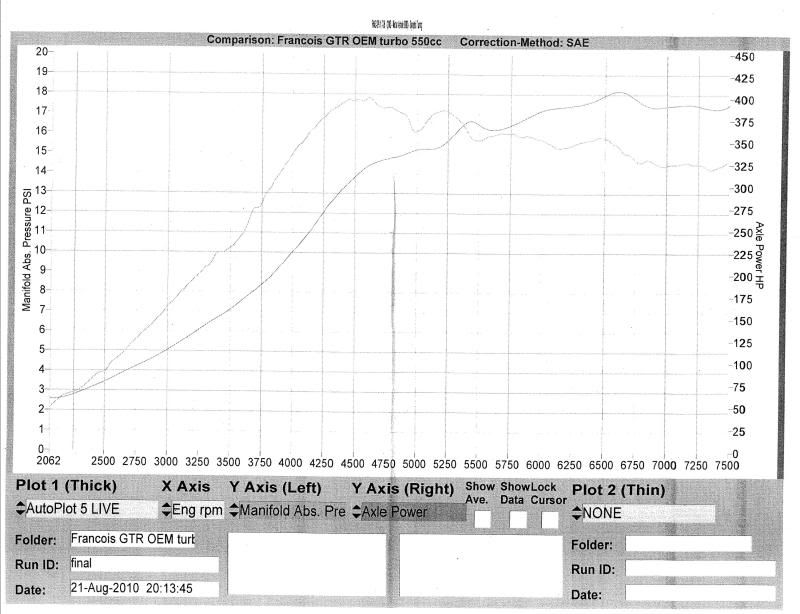

and it ended up beeing much worst, i was loosing tons of boost, and getting an erratic boost curve

to get the same 382whp as last year, we had to set it up to get a peak of 15,5psi then it dropped to 12psi to redline

so at the same boost settings as last year, i would loose power

help me analyse my problem with these charts

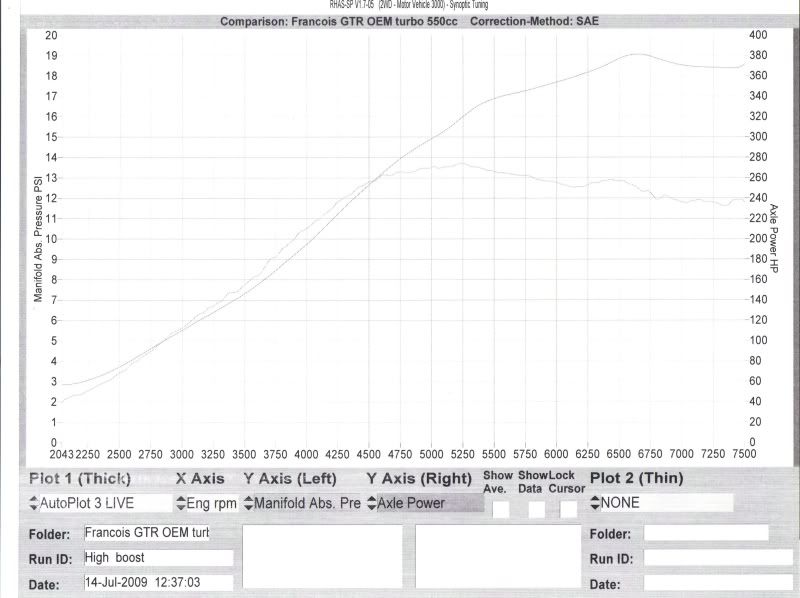

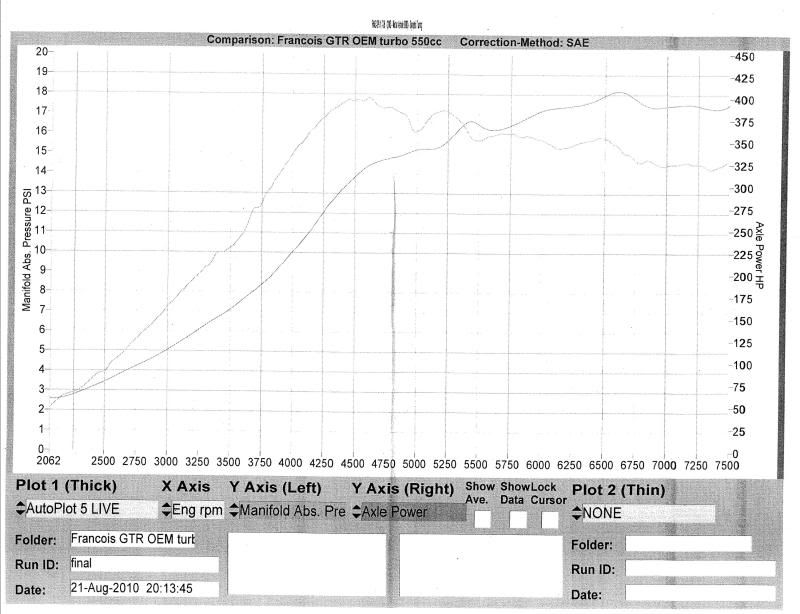

Boost VS Power

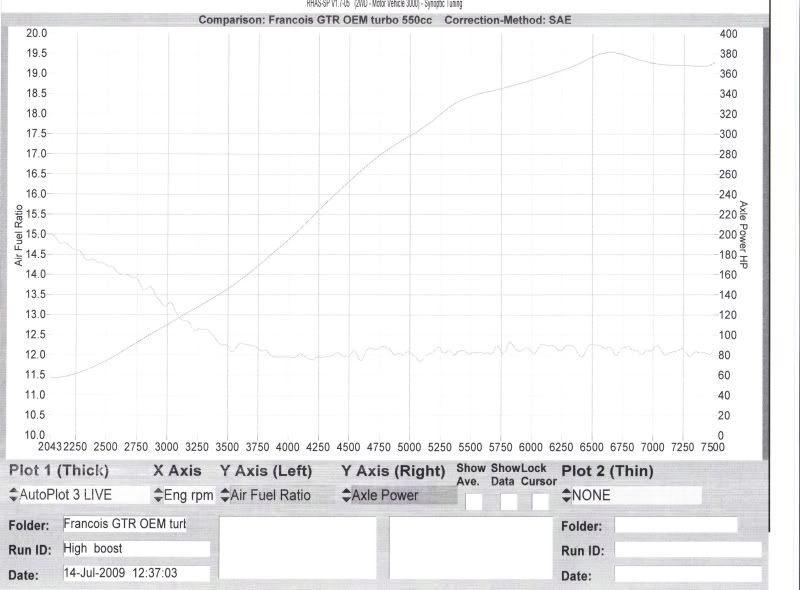

AFR VS Power

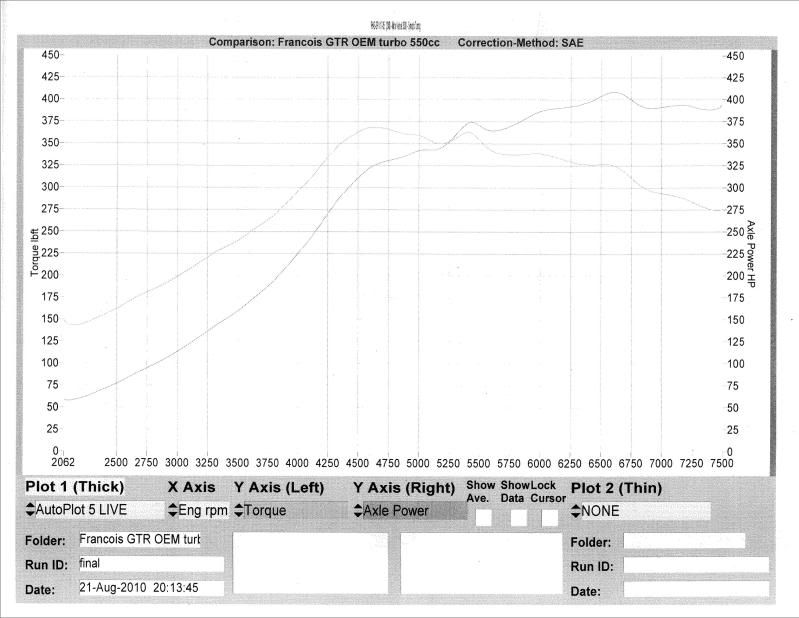

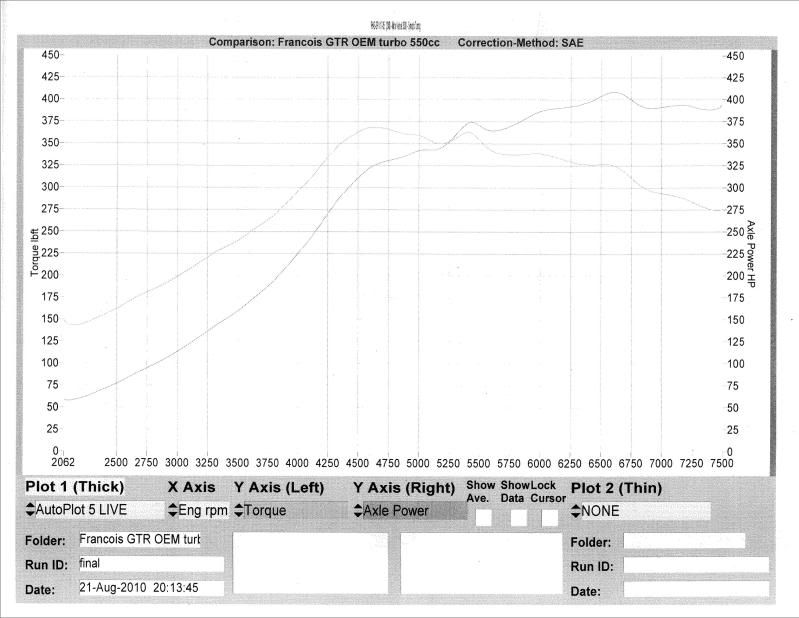

Torque VS Power

at first we thought the boost controller might have been setup wrong, but Mitch (Mitch32) and i checked it twice and it was perfect

then i was told the problem could have been my restrictive exhaust (i have an HKS Legal cat-back, but no cat and Nismo downpipe)

but it seemed odd to me that i upgraded the exhaust and the problem was worst

WTF

i checked my SSQV for leaks and they were fine

but i do have old school HKS race BOVs and the passenger side of the car,

because i didn't want those to mess up the ystem, i blocked the valves' exhausts and disconnected the vaccum port

now, could there valves be leaking and creating all this erratic boost issu?

i'm dropping the car off @ autoworx this week for other stuff, but i will ask them to check into this, and to take no chances, i'll ask them to remove those old BOVs and weld the flanges shut

anyone has ever had the same problem??

LAST YEAR, i got 382whp @ 6600rpm with 13,7psi peak boost

with AFRs at 12

but this year, i changed my old boost controller for a brand new HKS EVC-S, changed to brand new Splitfire Coilpacks, swapped the old recirc valves for brand new HKS SSQV BOVs and removed the cat in favor of a resonated test pipe

all those mods were to help minimize the boost drop, and make the turbos spool a bit faster

the HKS EVC-S was a pain in the ass to program and it seemed we never got what was programed,

and it ended up beeing much worst, i was loosing tons of boost, and getting an erratic boost curve

to get the same 382whp as last year, we had to set it up to get a peak of 15,5psi then it dropped to 12psi to redline

so at the same boost settings as last year, i would loose power

help me analyse my problem with these charts

Boost VS Power

AFR VS Power

Torque VS Power

at first we thought the boost controller might have been setup wrong, but Mitch (Mitch32) and i checked it twice and it was perfect

then i was told the problem could have been my restrictive exhaust (i have an HKS Legal cat-back, but no cat and Nismo downpipe)

but it seemed odd to me that i upgraded the exhaust and the problem was worst

WTF

i checked my SSQV for leaks and they were fine

but i do have old school HKS race BOVs and the passenger side of the car,

because i didn't want those to mess up the ystem, i blocked the valves' exhausts and disconnected the vaccum port

now, could there valves be leaking and creating all this erratic boost issu?

i'm dropping the car off @ autoworx this week for other stuff, but i will ask them to check into this, and to take no chances, i'll ask them to remove those old BOVs and weld the flanges shut

anyone has ever had the same problem??

Comment