Chapter 36 - The fix

so in the last chapter, i described how i had a huge p/s leak, and that my a/c belt had came off

but i kept driving the car around during the following week, so i did what any smart person would do in that situation...

my p/s pump was going to burn out because there was no fluid going thru it

and i didn't have to time to remove the radiator and a ton of stuff just to remove the belt

so i just cut it... i had another spare one anyway

the thing is that exactly 1 week after the track day, i was going up north to my chalet, a 4 hour drive,

so i really wanted my p/s and a/c to work for that trip

during that week i drove the car to work, without p/s, on the highway, it was a freaking pain!!! i couldn't feel my forearms when i got to work because i had to hold onto the steering wheel so much, darn 265 tires

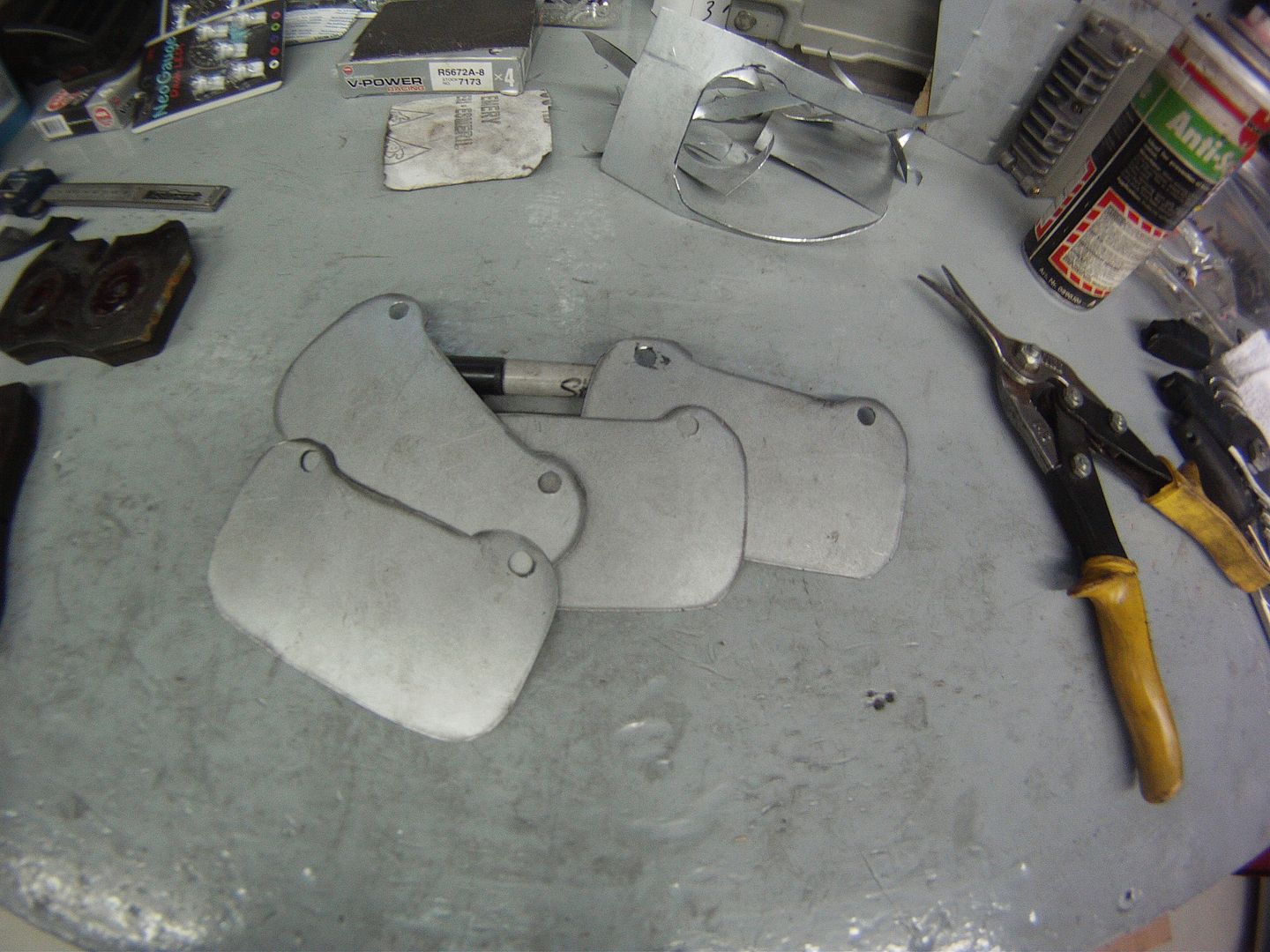

the first thing was to figure out why my brakes weren't doing crap, so i took the whole thing apart to inspect it ;

the rotors looked super glazed, no wonder why it wasn't braking

i took the pads off, and all the cylinders boots looked fine, no sign of damage anywhere

then i turned my attention to the rotors,

in an attempt to reduce the awfull awfull noize the Hawk HP+ were making (at that time) i chamfered the leading edge of each front pads

i also drove past AutoWorx and borrowed some leftover cans of Wurth Anti-squeal

after applying a good thickness, i put everything back together

i then check the wear of my front tires and quickly realized i couldn't finish my summer with sooo much camber wear

the problem wasn't actual camber, but way too much toe out, because like an asshole i had changed the alignment front VAG Motorsport's settings because they were a bit too extrem

so i went to a tire shop that my dad often deals with, and had both front tires flipped, meaning that the camber wear would now be on the outside of the tire rather than the inside

it looked like ****, but at least i could drive for the remainder of the season

---------------------------------

the next day, i checked what my p/s and a/c problem was

and sure enough i had lost the complet a/c tension pulley assembly, so i got on GTRC and found another one, rather quickly

i then saw that my main p/s hose was cracked open,

after looking under the car i realized that line was part hardline part hose, but 1 piece all the way from the p/s pump tp the rack&pinion head

so, seeing this was going to be a real PITA to fix, i enlisted the help of my father for a rare occasion

first i had to remove the radiator, argh

both of us spent a good 3 hours underneath the car to remove the line without bending it too much since i didn't want to replace the whole thing

we had to snake it thru the subframe, motor mounts, swaybar, etc, etc...

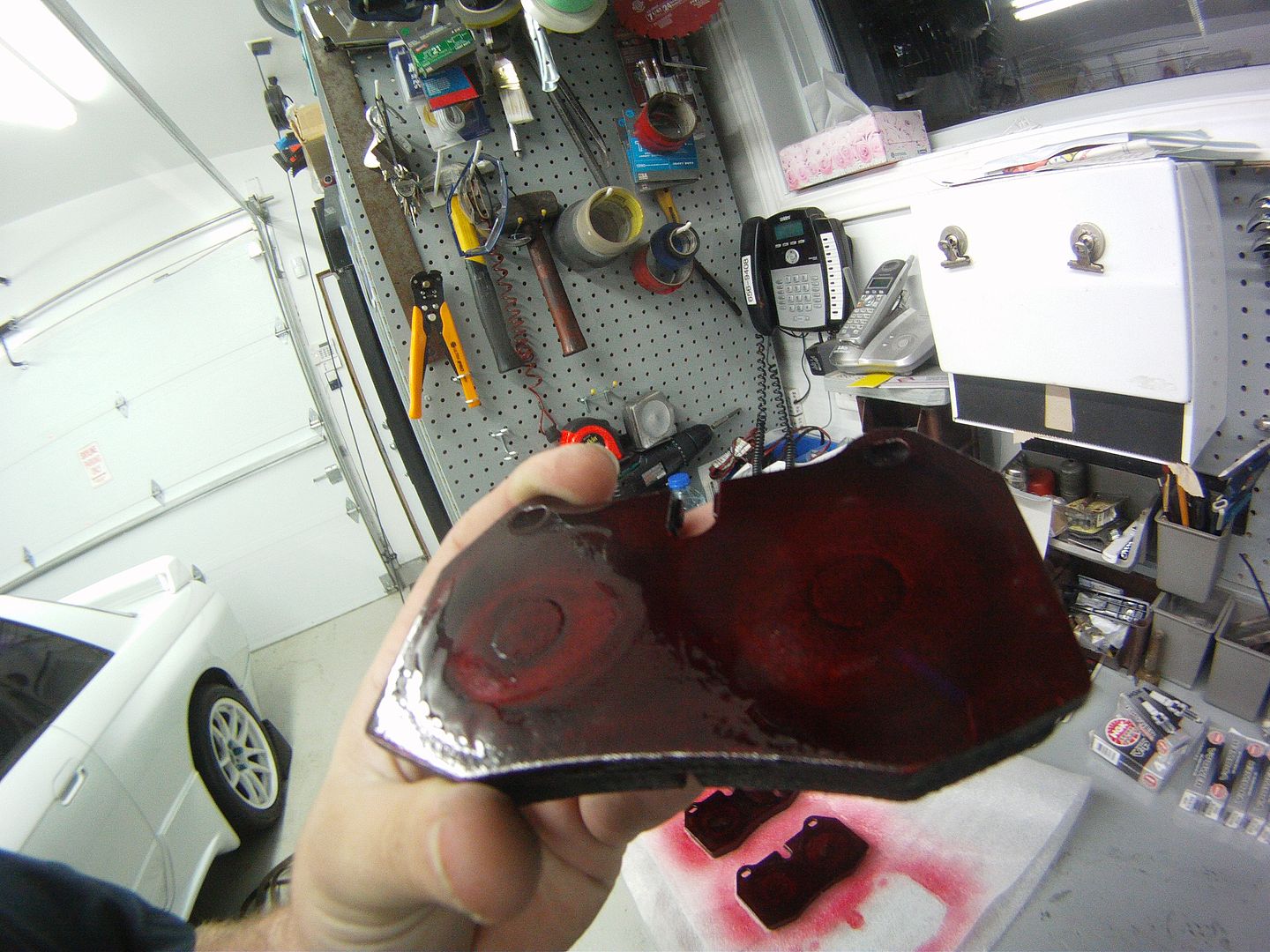

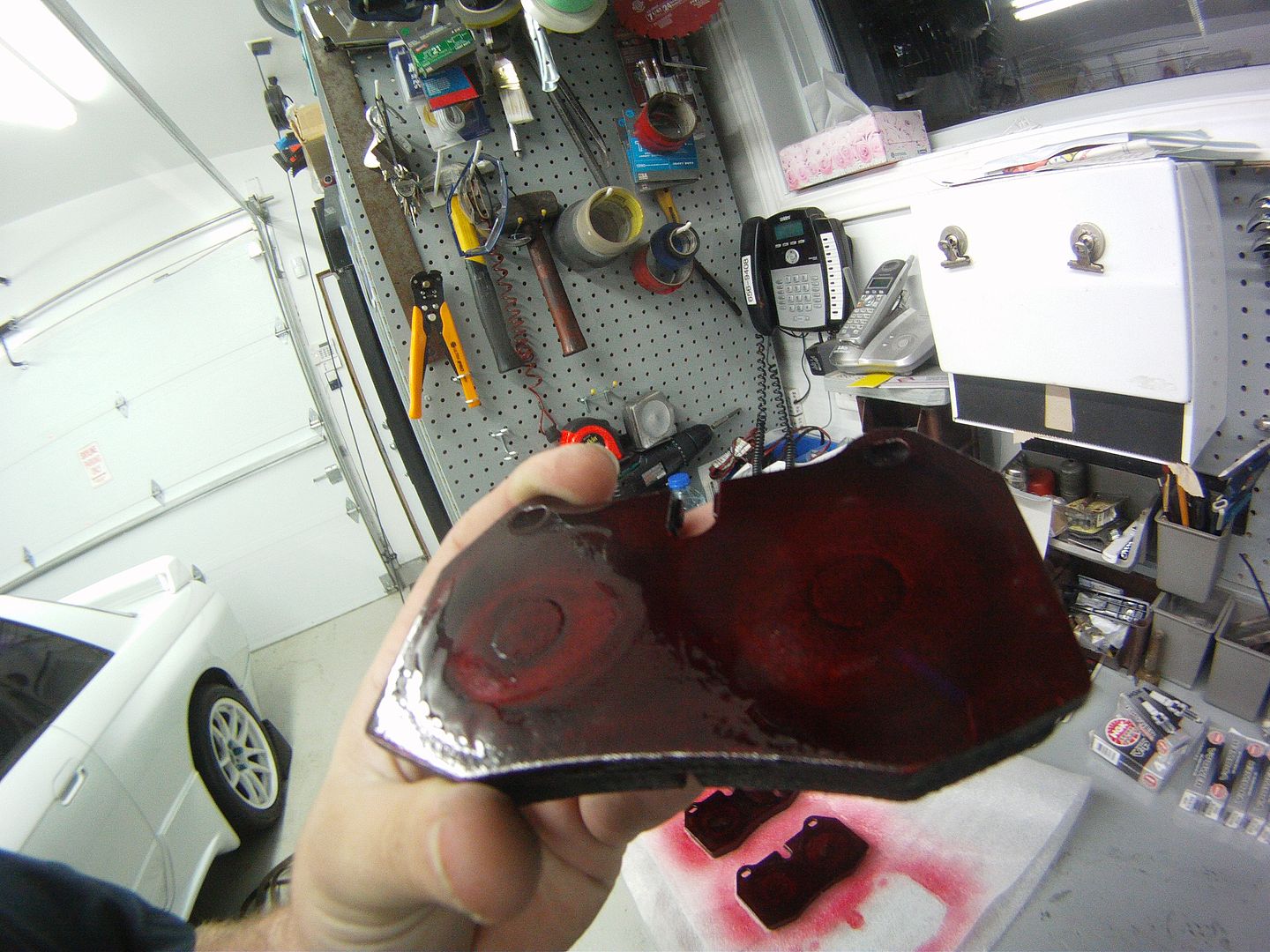

and this is what the whole fawking thing looks like

believe me you do not want to replace this line, it is by far the worst job i've ever done on my car

the soft part of the hose was completely torn open, even though its super thick and solid

i called Nissan just for kicks, and the line was worth something like 300$

and would take 3 weeks to arrive from japan

since i didn't have time to get it fixed myself, my dad brought it to an hydraulics shop

they didn't have the same fittings to go into the p/s pump (DUHH) so i told my dad to get something as similar as possible

and also, the facilitate the "putting it back on" part, i told him to get the line cut into 3 section and using fittings we could assemble it back on the car

but, just my luck he had it cut just a couple inches from the spots we had discussed

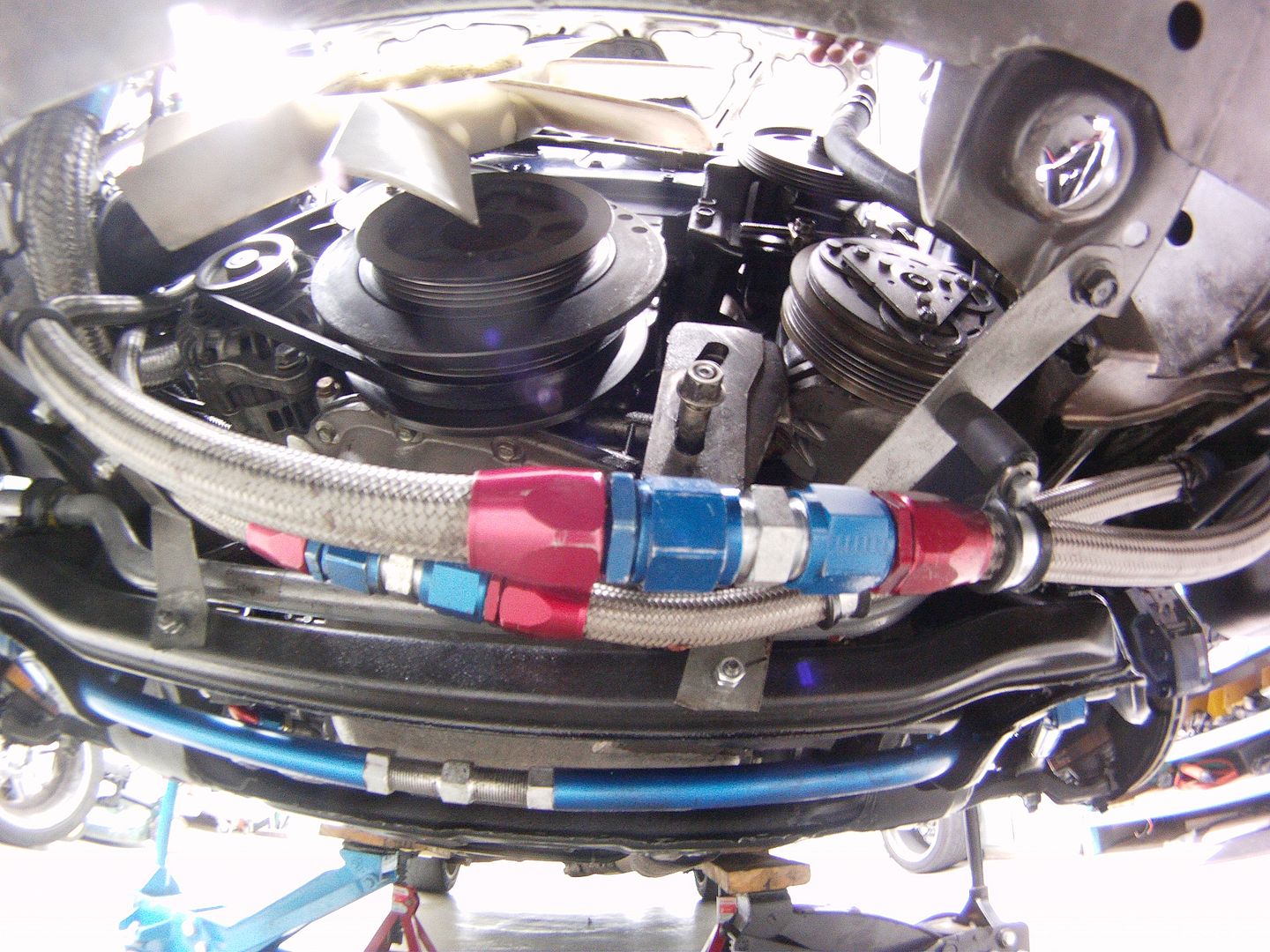

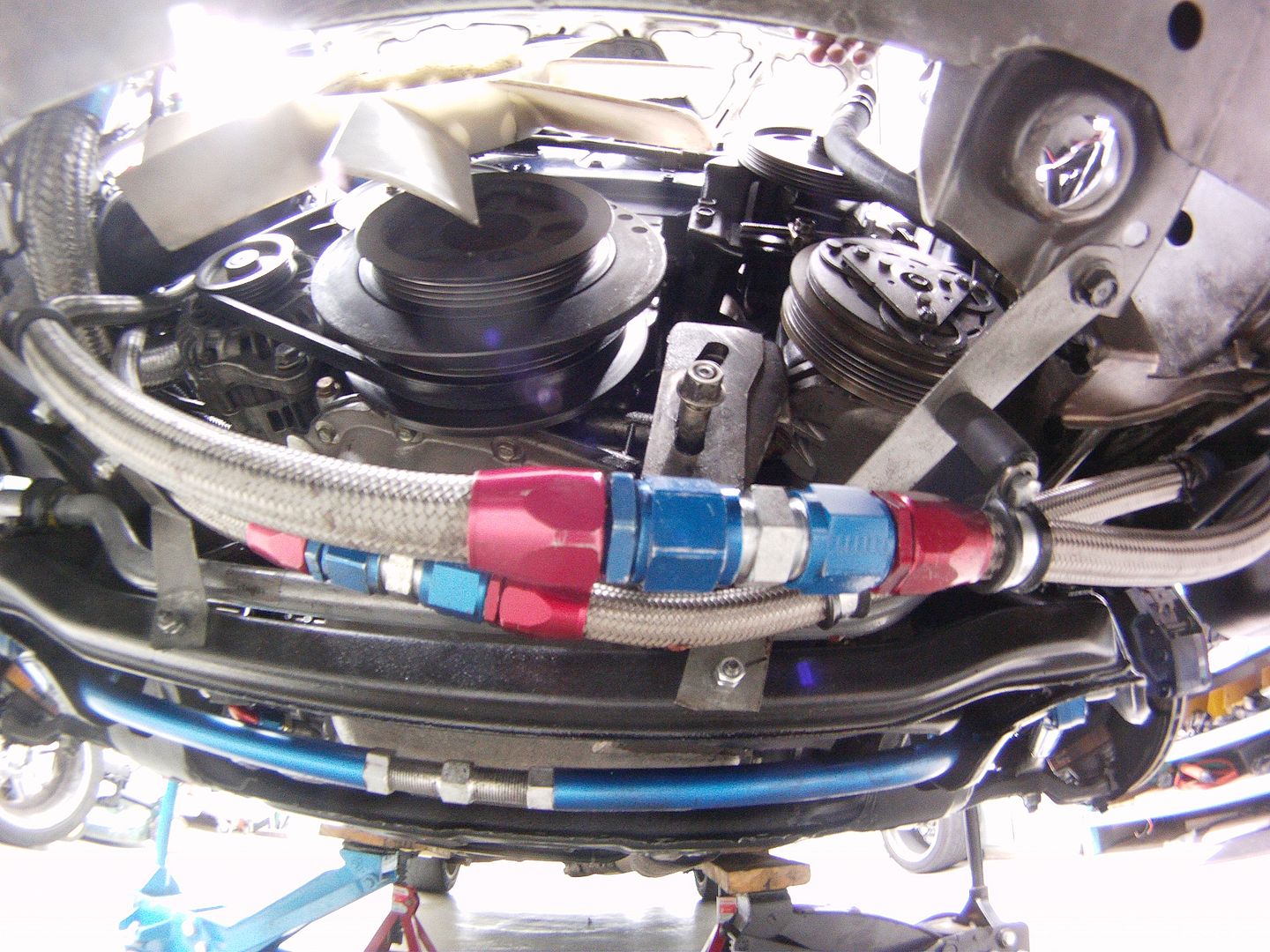

this is how it looked

how the assembling fittings look

the crimped section

and the end fitting, which looked completely different

problem is, we had received the line on the friday, when i was supposed to leave at the break of dawn on the following day

so on friday night, my dad and i went back under the car to get the line back into place

but since the assembling fittings weren't in the right spots, it actually made it even more difficult to fit because we couldn't reach the fittings with tools to tighten them up

it took another 3 hours just for that

but out of luck, the standard banjo fitting at the end of the line was just the right size to fit on the p/s pump and into the bracket that prevents it from rotating

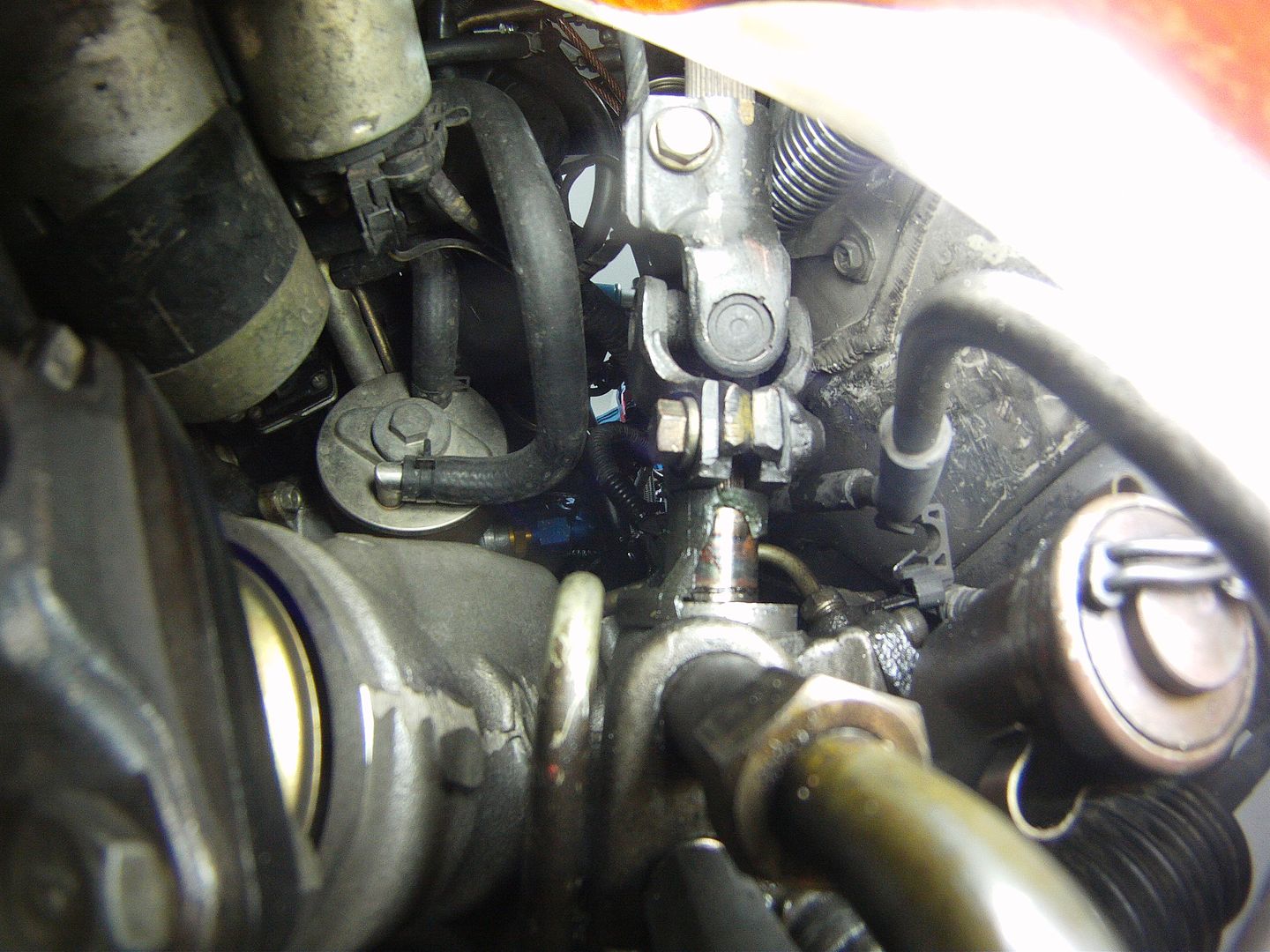

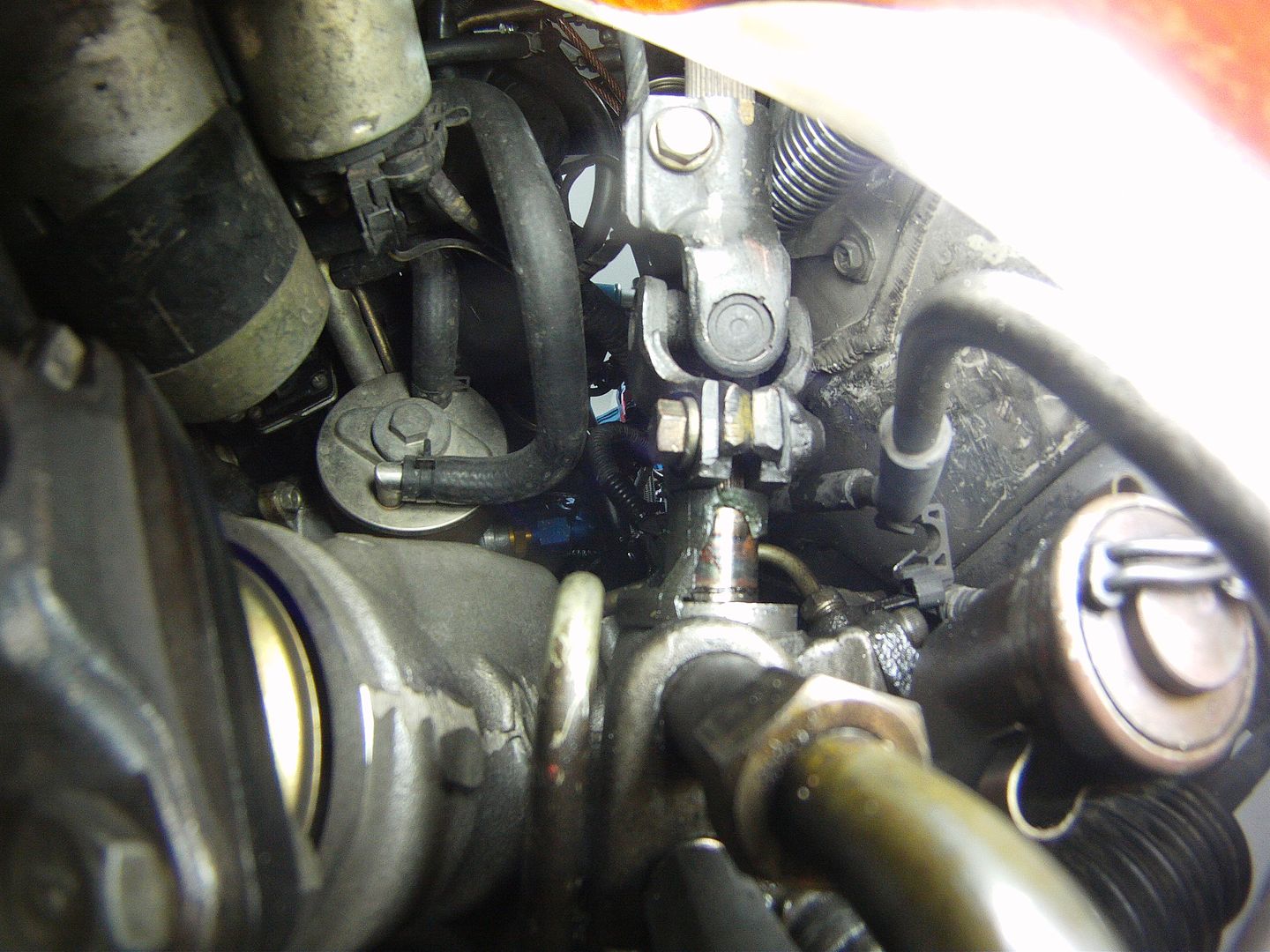

while working on that, i saw that the dust cover on top of the rack&pinion was cracked, and that the rack&pinion itself was leaking just a bit

but i realized, that it would have been much smarter to simply replace the whole line with a complete soft line (high-pressure nylon braided line), it would have been much easier to re-install, and much more reliable (as you'll see later in another chapter)

after that, it was already pretty late, but before putting the radiator back on, i wanted to fix the A/C

luckily i had received a pulley from Brian Ellis (Bellis)

quickly i bolted the pulley assembly onto the car, but since the original one wasn't there at all anymore, i couldn't compare

i fitted the spare A/C belt over it

reassembled all the other belts, the fan, and put the radiator back on

then i filled the radiator simply with (inexpensive) distilled water, and a bottle of Redline WaterWetter to make the water more viscous

filled the p/s system with good quality fluid

after everything was reassembled, only then did i start the car to see if there was any problem

there was no leak, but a loud ''squeak'' could be heard

it wasn't coming from the p/s pump

but when i checked underneath the car, the sound was louder

so i stopped the engine, and started it again

it was clear the noize was coming from the freshly installed a/c pulley

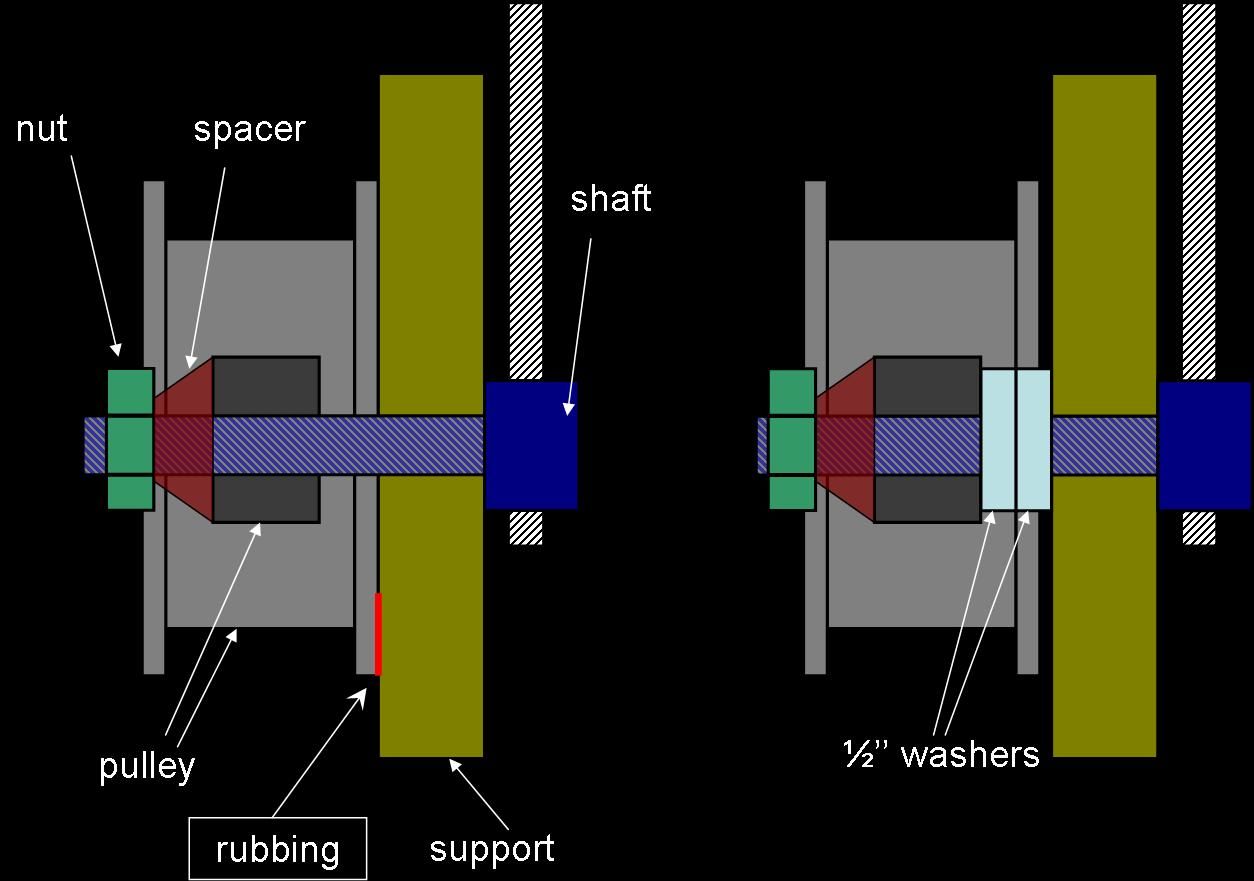

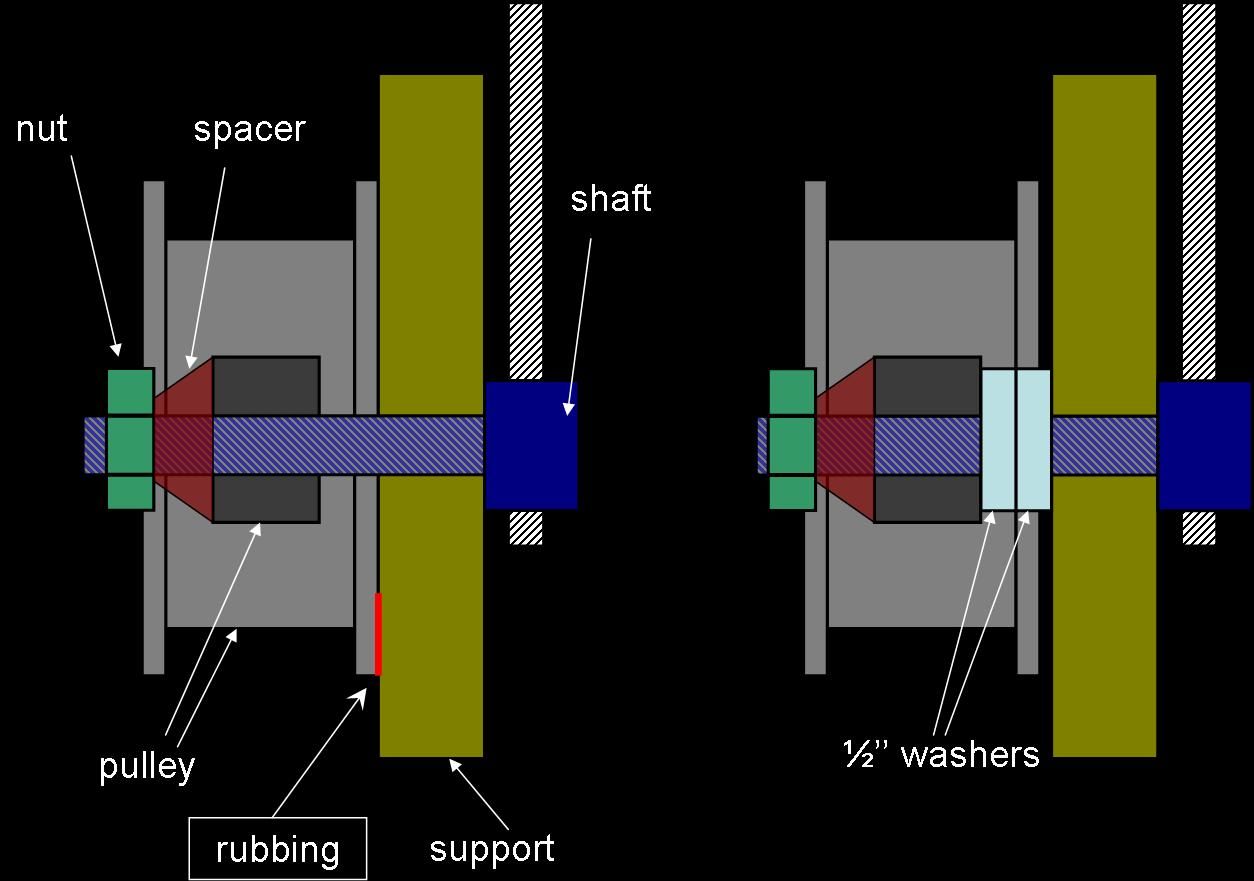

i could even see rubbing marks on the support right behing it

only when i saw the pulley jam, and the belt still turning and .. smoking did i yell to my dad to stop the engine

it was clear i was missing some sort of spacer between the pulley and the support

so i sent a text to Brian, asking if he had sent everything related to the pulley's assembly and he replied that he did

my dad was looking at me, with a look that meant 1 thing; ''son, we're going to have to take it appart again''

ohhhhh no

by taking the nut of the pulley and prying it a bit, i was able to take it off the shaft without having the belt slide off the pulley

so at first i slid a 1/2" washer on the shaft, to space the pulley outward, and tighten the pulley back on

started the car, and saw that it wasn't enough

fuuuuuuuuu

so i did the exact same thing a second time, and with two 1/2" washers, the problem was resolved

even though it was close to midnight at that point, i still decided to check the spark plugs, since it was a 600km ride in the following days

i cleaned the plugs, and everything was fine!

so the next day, saturday, i got up at 6am, and drove my perfectly functionning car all the way to my chalet

so in the last chapter, i described how i had a huge p/s leak, and that my a/c belt had came off

but i kept driving the car around during the following week, so i did what any smart person would do in that situation...

my p/s pump was going to burn out because there was no fluid going thru it

and i didn't have to time to remove the radiator and a ton of stuff just to remove the belt

so i just cut it... i had another spare one anyway

the thing is that exactly 1 week after the track day, i was going up north to my chalet, a 4 hour drive,

so i really wanted my p/s and a/c to work for that trip

during that week i drove the car to work, without p/s, on the highway, it was a freaking pain!!! i couldn't feel my forearms when i got to work because i had to hold onto the steering wheel so much, darn 265 tires

the first thing was to figure out why my brakes weren't doing crap, so i took the whole thing apart to inspect it ;

the rotors looked super glazed, no wonder why it wasn't braking

i took the pads off, and all the cylinders boots looked fine, no sign of damage anywhere

then i turned my attention to the rotors,

in an attempt to reduce the awfull awfull noize the Hawk HP+ were making (at that time) i chamfered the leading edge of each front pads

i also drove past AutoWorx and borrowed some leftover cans of Wurth Anti-squeal

after applying a good thickness, i put everything back together

i then check the wear of my front tires and quickly realized i couldn't finish my summer with sooo much camber wear

the problem wasn't actual camber, but way too much toe out, because like an asshole i had changed the alignment front VAG Motorsport's settings because they were a bit too extrem

so i went to a tire shop that my dad often deals with, and had both front tires flipped, meaning that the camber wear would now be on the outside of the tire rather than the inside

it looked like ****, but at least i could drive for the remainder of the season

---------------------------------

the next day, i checked what my p/s and a/c problem was

and sure enough i had lost the complet a/c tension pulley assembly, so i got on GTRC and found another one, rather quickly

i then saw that my main p/s hose was cracked open,

after looking under the car i realized that line was part hardline part hose, but 1 piece all the way from the p/s pump tp the rack&pinion head

so, seeing this was going to be a real PITA to fix, i enlisted the help of my father for a rare occasion

first i had to remove the radiator, argh

both of us spent a good 3 hours underneath the car to remove the line without bending it too much since i didn't want to replace the whole thing

we had to snake it thru the subframe, motor mounts, swaybar, etc, etc...

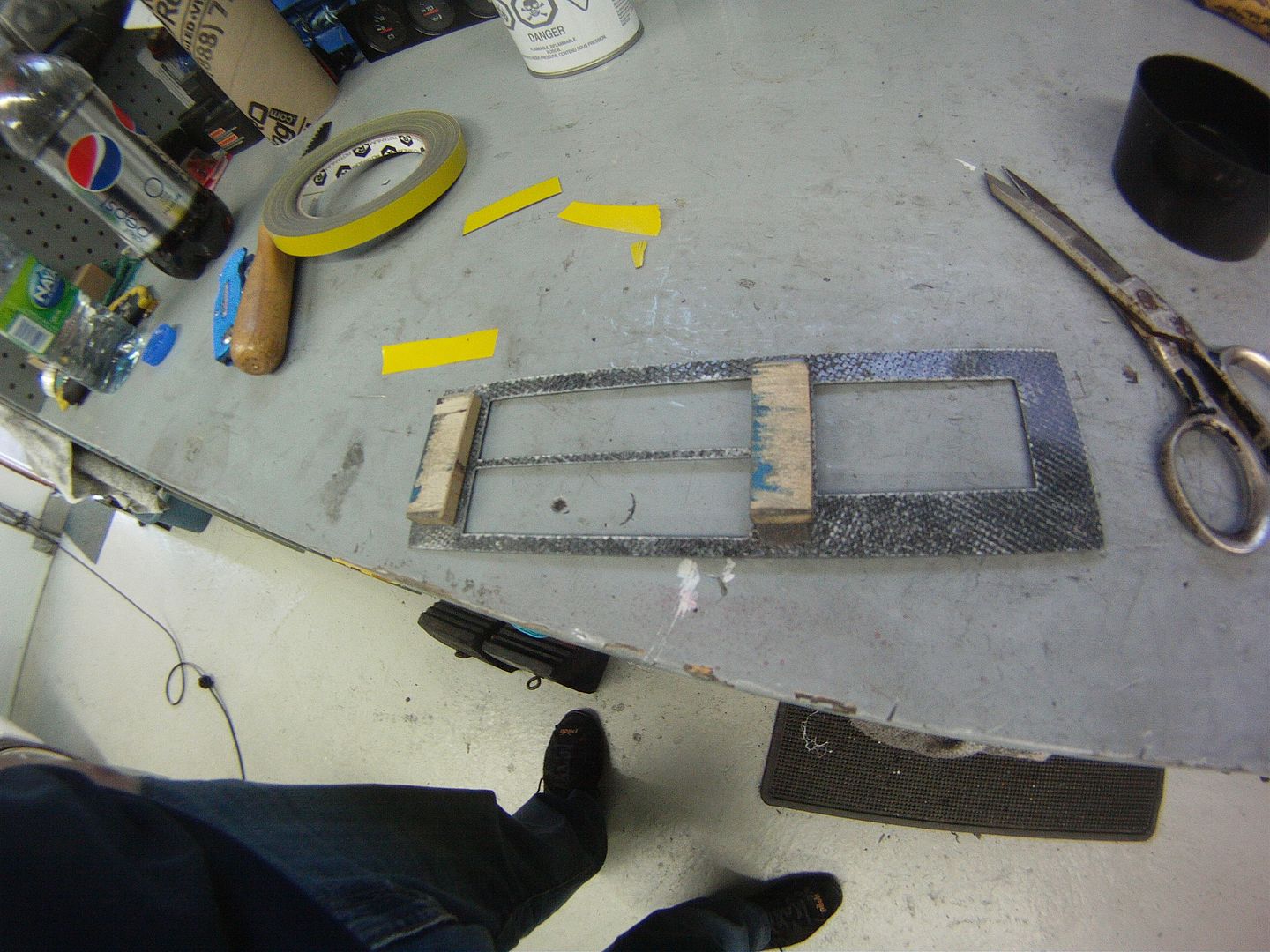

and this is what the whole fawking thing looks like

believe me you do not want to replace this line, it is by far the worst job i've ever done on my car

the soft part of the hose was completely torn open, even though its super thick and solid

i called Nissan just for kicks, and the line was worth something like 300$

and would take 3 weeks to arrive from japan

since i didn't have time to get it fixed myself, my dad brought it to an hydraulics shop

they didn't have the same fittings to go into the p/s pump (DUHH) so i told my dad to get something as similar as possible

and also, the facilitate the "putting it back on" part, i told him to get the line cut into 3 section and using fittings we could assemble it back on the car

but, just my luck he had it cut just a couple inches from the spots we had discussed

this is how it looked

how the assembling fittings look

the crimped section

and the end fitting, which looked completely different

problem is, we had received the line on the friday, when i was supposed to leave at the break of dawn on the following day

so on friday night, my dad and i went back under the car to get the line back into place

but since the assembling fittings weren't in the right spots, it actually made it even more difficult to fit because we couldn't reach the fittings with tools to tighten them up

it took another 3 hours just for that

but out of luck, the standard banjo fitting at the end of the line was just the right size to fit on the p/s pump and into the bracket that prevents it from rotating

while working on that, i saw that the dust cover on top of the rack&pinion was cracked, and that the rack&pinion itself was leaking just a bit

but i realized, that it would have been much smarter to simply replace the whole line with a complete soft line (high-pressure nylon braided line), it would have been much easier to re-install, and much more reliable (as you'll see later in another chapter)

after that, it was already pretty late, but before putting the radiator back on, i wanted to fix the A/C

luckily i had received a pulley from Brian Ellis (Bellis)

quickly i bolted the pulley assembly onto the car, but since the original one wasn't there at all anymore, i couldn't compare

i fitted the spare A/C belt over it

reassembled all the other belts, the fan, and put the radiator back on

then i filled the radiator simply with (inexpensive) distilled water, and a bottle of Redline WaterWetter to make the water more viscous

filled the p/s system with good quality fluid

after everything was reassembled, only then did i start the car to see if there was any problem

there was no leak, but a loud ''squeak'' could be heard

it wasn't coming from the p/s pump

but when i checked underneath the car, the sound was louder

so i stopped the engine, and started it again

it was clear the noize was coming from the freshly installed a/c pulley

i could even see rubbing marks on the support right behing it

only when i saw the pulley jam, and the belt still turning and .. smoking did i yell to my dad to stop the engine

it was clear i was missing some sort of spacer between the pulley and the support

so i sent a text to Brian, asking if he had sent everything related to the pulley's assembly and he replied that he did

my dad was looking at me, with a look that meant 1 thing; ''son, we're going to have to take it appart again''

ohhhhh no

by taking the nut of the pulley and prying it a bit, i was able to take it off the shaft without having the belt slide off the pulley

so at first i slid a 1/2" washer on the shaft, to space the pulley outward, and tighten the pulley back on

started the car, and saw that it wasn't enough

fuuuuuuuuu

so i did the exact same thing a second time, and with two 1/2" washers, the problem was resolved

even though it was close to midnight at that point, i still decided to check the spark plugs, since it was a 600km ride in the following days

i cleaned the plugs, and everything was fine!

so the next day, saturday, i got up at 6am, and drove my perfectly functionning car all the way to my chalet

Comment