Its almost tomorrow afternoon..

Announcement

Collapse

No announcement yet.

Frankiman's street/track GTR project

Collapse

X

-

-

Chapter 42 - Interior works

week5 - 2011, part 1/2

disclaimer :

the following story depicts actions that occured between May 27 and june 4 2011

information is recalled purely from memory, endure with me

if you've read the last chapter, you know i had been working on modifying a Cusco roll cage during week4

after all the hole were drilled in the brackets and the harness bar, i bolted it all together to check for fitment;

since the harness bar was a bit too long for no good reason, i cut off bits of it at each end;

then i buffed alot of the rust off the feet of the main hoop, i don't know why it was so corroded there and where the paint had gone;

then to make it all look better and eliminate sharp edges, i traced a round cercle on the brackets were i'd cut some of it off;

my dad came to help me, since what was done next couldn't easily be done alone,

standing outside the garage, my dad was holding the hoop firmly while I was using a cutter/grind electric tool to cut the thick steel brackets into shape,

after all of the brackets were cut, i spend a good amount of time smoothing all the edges with my pneumatic sander;

i also did the same to the 'fixed' cross brace;

i then cut 1/8" steel plate about the size of the hoop's feet, and drilled matching holes in them,

these plates would go underneath the car to bolt the cage onto the floor;

using some of the hardware i had bought, i test fitted the plate with the hoop;

then i had a brilliant idea on a setup that would allow me to store anything on the new backseat,

it will all make sens in time,

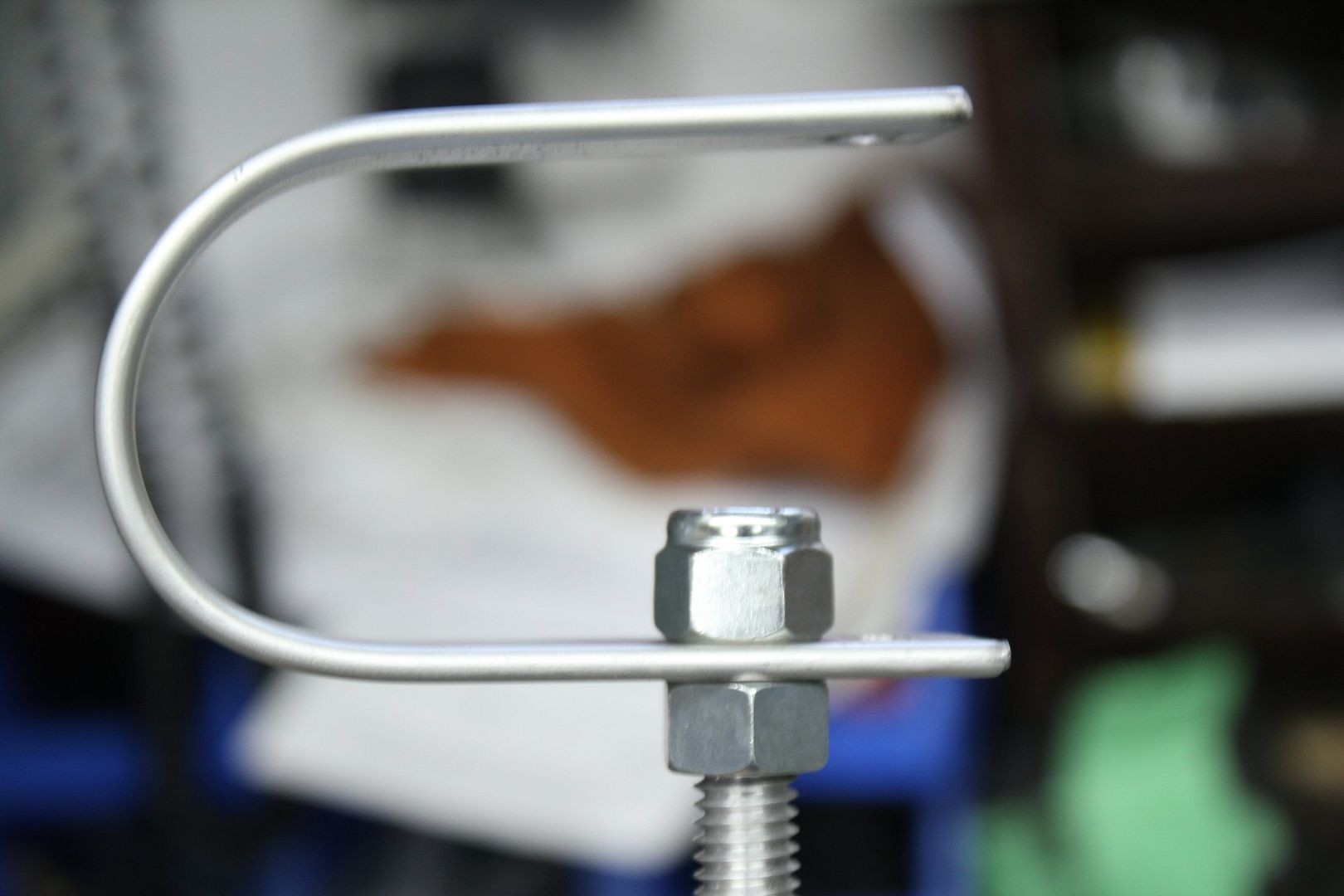

i cut and bent small bars of aluminium, drilled and tapped holes in them to make little 'C' clamps like such;

i had bought 4' long 3/8" aluminium rods, which were the exact lenght i'd need,

so i threaded about 2" after each of the ends;

so the rod could be bolted to the clamps as such;

and finally this is what it ended up looking like,

this is not made to be structural at all;

thats all about the cage for week5, more in next week's update

----------------------------------------

my buddy also came back during that week to continue work on the A/C control module's harness which was coming along nicely

thats not all for week5, keep reading -->

Comment

-

Chapter 42 - Interior works

week5 - 2011, part 2/2

disclaimer :

the following story depicts actions that occured between May 27 and june 4 2011

information is recalled purely from memory, endure with me

the work on the new back seat area continued,

while messing around inside the car, i found out that a 1/8" bar would fit perfectly in the hooks that usually hold the back seat in place,

this would be a defining discovery for my design;

using yet another piece of cartboard, i conituned mocking up the boards i'd make for the back seat area,

whilst considering the roll cage and racing harness;

then i called upon yet again the help of my father, since his original trade was carpentry,

he was very skillful with saws, mostly circular saws,

i bought a 4x8 panel of 1/2" plywood at home depot, which would be plenty;

using the cartboard mock-ups, i traced the outline on the plywood;

then simply watched my father work his magic,

i test fitted the panel after the first raw cut, then many adjustments were done ;

when the deck was finalized, my dad made me realize i didn't consider the thickness of the wood whilst cutting the mock-ups,

so other adjustments had to be done prior to cutting;

we reapeted the same steps for the back rest;

this was the end result;

with the deck in place, i traced lines collinear to the supports undeneath, to drill some holes

i drilled and tapped the supports to yet again avoid the use of nuts;

i did the same with the back rest, but using masking tape, collinear to the bar behind it;

then drilled and tapped the bar;

to cover up the ugly plywood i wanted a nice tough dark-ish textured fabric,

but to avoid having the fabric getting ripped by some splitters of the plywood,

i glue a layer of wrapping foam on both the deck and the back;

then i called upon the help of my mother, who is an outstanding seamstress in her free time,

she had found the exact fabric i wanted,

she cut the fabric in the shape of the panel, with a bit more extra, and sewed the edges;

the rest of the fabric was wrapped around and stapled behind,

the end result looked awesome!

we did the same with the back rest, but i added something extra,

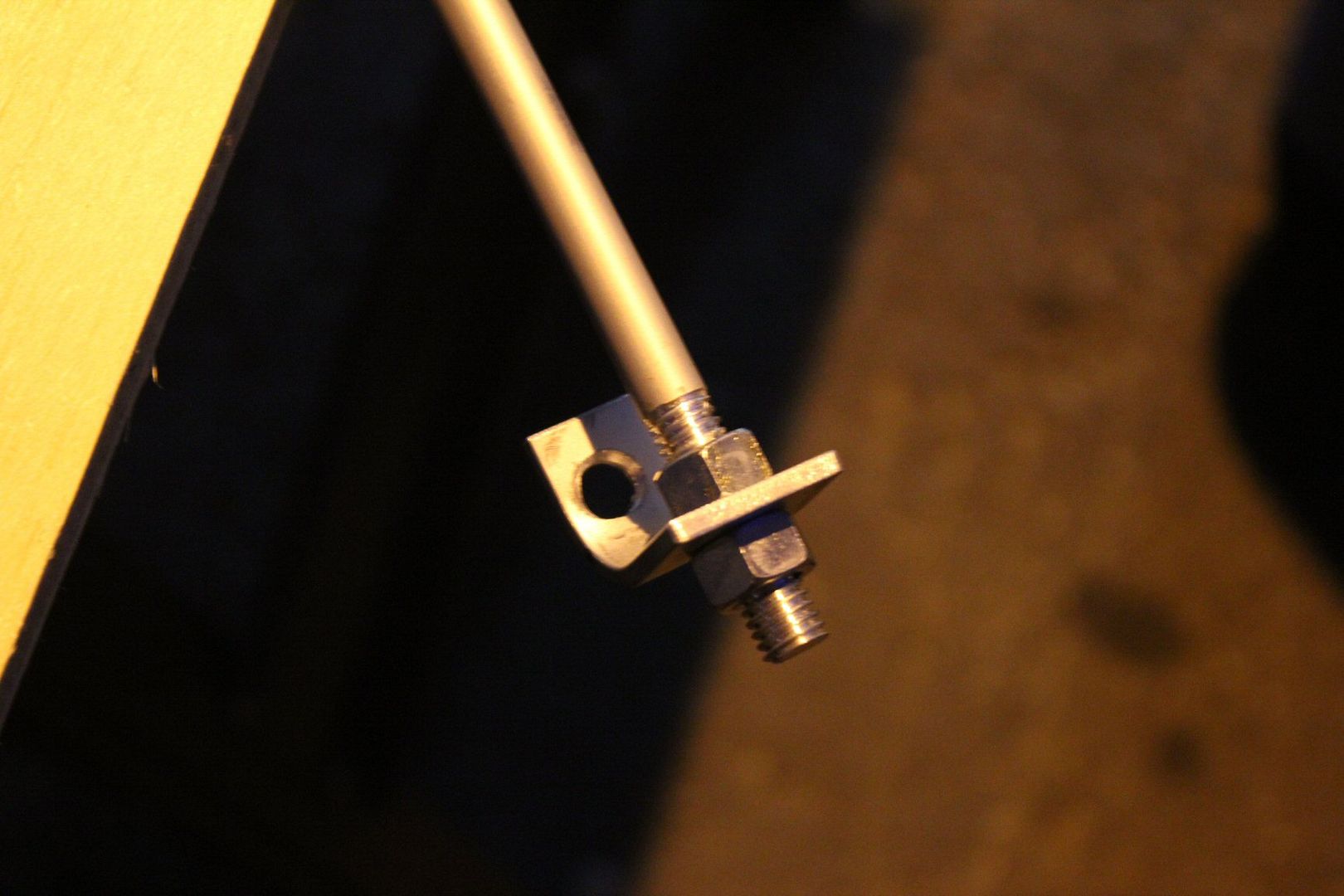

i modified another 3/8" aluminium rod and made 3 brackets to hold it;

to make sure it wouldn't tear through the wood, this is how it would be fastened;

my mom and i finished up the back rest, while clever techniques to hide seams and edges and such;

i bolted the rod to it;

then i punched holes in the fabric where all the holes i drilled in the wood were,

i even modified countersunk screws the make it much much easier to align them into the respective holes in the aluminium brackets,

using these screws, their heads would be flush with the surface of the boards, for a clean look

for the back rest, the fabric was longer at the bottom and the top,

to hide the holes for the racing harness at the bottom,

and to hide the edge of the speaker deck at the top,

this was the final result;

more on this and the cage in the week6 update soon

stay tuned!

thanks for reading!Last edited by frankiman; 03-12-2012, 11:55 AM.

Comment

-

Do you have a corduroy Skyline?

Comment

-

Will that cage be track legal (like the nhra or whatever) Who do you get to approve it being homemade?

Heh, nice "picnic" table for a back seat Black 1991 GTR. Serious garage stand mantle/parts car.

Black 1991 GTR. Serious garage stand mantle/parts car.

Black 1990 Pulsar GTiR. Sold

Silver 1989 GTR. Sold

Black 2010 Subaru WRX. Weekend warrior. Sold.

Black 2013 F-150 FX4 ecoboost. Daily driver.

White 2012 Ford Explorer Limited. Family wagon.

Sorry for my offensive comments, I r socially retard.

lolstart by having A ROLLING GTR then we talk u ******* mofo funzy little *****

Comment

-

the cage itself would probably be legal, but i scrapped the homologation sticker off when i painted it,Originally posted by NismoS-tune View PostWill that cage be track legal (like the nhra or whatever) Who do you get to approve it being homemade?

Heh, nice "picnic" table for a back seat

but the harness bar for sure wouldn't be legal, but could still pass inspection

but anyway, i don't think i'll ever enter an event where those things are required, its mostly club racing thats requires that, i do lapping and time attack

and you'll see when that back seat is done

good, go write some!Originally posted by Willis View PostJust read this thread start to finish. Nice thread man! I never thought to use my gopro in the garage, might have to start. Beats using my iphone.

Reading your thread actually gave me some motivation to update my own thread.

Sexy car

and thx

Comment

-

Chapter 43 - Interior Works continued

week6 - 2011, part 1/2

disclaimer :

the following story depicts actions that occured between June 6 and 11 2011

information is recalled purely from memory, give me a chance

if you've read the last chapter, you know i was hard at work making a custom rear seat section

you have to remember that this setup is not for seating people,

but since i knew my back seat couldn't be used anymore with my cage in place,

and i didn't want to simply remove the back seat and have to look at the ugly inner sheet metal,

so i decided to make something that looked oem, was much more practical but still lighter than stock

with the way the OEM GTR rear seats are its an assle to store anything on them,

but with the much thinner and flat panels, alot more stuff can be stored behing the front seats

last week i had actually finished the install of the new panels, but some bodywork could still be seen in some places,

so i cut up a couple more pieces of fabric that i glued in those spots,

the middle and the inner fenders (pictured later);

also, this is how the surface of the panels looked when screwed into their support;

------------------------------------

back to the cage,

the week prior, i had finished setting up the cage and was ready to paint it,

i sanded all of the parts down to a smooth matte surface,

then outside with a ladder and used a bunch of hook straps to hang all the cage parts in my good ol' maple tree;

i started with 2 coats of primer;

and tried to get the paint in every little spaces,

but doing this outside meant i had to work with a good amount of wind that day,

which made it all much more complicated;

after that i started spraying Tremclad industrial semi-gloss black paint;

spraying all the parts in the wind took about 15 minutes for each coat,

for good durability i wanted to have at least 10 coats on there,

but with so many parts to paint and the day coming to an end,

i quickly realized i was going to run out of two things;

1- daylight

2- paint

so between two coats, i quickly drove to home depot (which is a blocks away) and got some more cans before it closed;

and since i didn't want the paint to dry up and start again the next day, i decided to just keep painting it in the dark,

again between two coats, i grabed a bunch of 300 watt lights with electrical cords and setup 3 lights around the tree;

(don't be fooled by the image, i ajusted the camera for more light but it was almost completely dark at the time)

i kept going well past 11pm, just sitting in a lawn chair drinking beer,

my neighboors were probably wonderiing wtf i was going that late lighting up my tree;

after it 10 or so coats, when it was dry to the touch, i took it back inside the garage to dry overnight,

i setup a clever type of clothes line to have all the pieces hanging away from the car, in front of the fan and unable to hit each other if something started to sway;

in total I used almost 5 cans of paint

when i got the chance to work on it again, it was 2 days later, so the paint was perfect,

but since its semi-gloss paint with no clear coat, it was still very vulnerable to scratches,

so i wrapped it all in newspaper before putting it back into the car;

but now none of the holes had been drilled in the floor and fenders to bolt the cage in,

so i placed all the pieces where they would be,

and using a super practical Mastercraft right angle drill in got from the in-laws, i was able to drill in the sheet metal through the mounting holes of the cages bars while beeing very uncomfortably twisted working in a tight environnement,

thanks drill;

with the fabric, it looked seamsless;

this is the hardware i would use, high grade bolts with nylon locknuts,

and rubber washers on the underside to make it water tight,

i wouldn't want water comming it from the fenders now would i?

the bolts would obviously be upwards, with the bolt heads sitting just over the rear tires inside the fenders;

the floor it was easy to drill through, was since its an uneven surface because the sheetmetal is ondulated for ridgidity,

its hard to drill exactly where you want to since the drill bit always wants to go into a crevasse,

and there is alot of insulation material that gets stuck in the drill bit too, even stopping it from spinning,

but finally, holes were done and the hoop was bolted down...

with the large backplates underneath;

then the newspapaer wrap came off and all the main parts were bolted to each other;

this was the final result,

(the driver-only harness bar idea was later dropped because of its lack of ridgidity in favor for the full width bar,

it looked so great, and the way i made it you can't see any sheet metal, not even the holes where the harness go through;

after that i added the strap bar, now its much easier to understand my vision of this bar

i glued a little rubber pad on the inside of the U bracket to make sure the bar wouldn't slide up and down the hoop,

with both the lower and upper rods, i can strap any big object in the back seat while making sure it doesn't move using straps;

for example, heres a crappy picture i took with my cellphone much later in the summer during a roadtrip with my girlfriend,

we put a cooler, bags of food, pillows and blankets back, it was very useful;

i later changed the bolts inside for pure Ti ones, for obvious reasons;

that was that for the cage install

keep reading for more --->Last edited by frankiman; 03-19-2012, 11:01 PM.

Comment

-

Chapter 43 - Interior Works continued

week6 - 2011, part 2/2

disclaimer :

the following story depicts actions that occured between June 6 and 11 2011

information is recalled purely from memory, give me a chance

if you've read the last chapter, you'll also know i was working on relocating the Climate control module to the armrest

by now, my buddy had all 36 wires extended,

it was now time to put the wiring harness back into the car, it got pretty caotic under the dash;

beeing a true pefectionnist, my buddy wanted to make the install as well as possible,

a little taped in and there cleaned it all up;

not easy to work under there;

the whole harness was passed behind and then through the instrument panel;

the two main sections of the harness were in a plastic loom, to make it cleaner (again),

we ran them around the shift lever to the armrest;

i cut a hole in the bottom of the armrest's storage compartment for the harness;

i shaved the mounts off the control module to make it fit inside the compartment;

and voila, the module fits tightly into the compartment, and it doesn't look bad at all,

as simple as that, all i had to do was put the armrest back in place;

then i realized why the armrest always felt like wobbling, the screw it closes on was wrong, heh?

------------------------------

in other news,

i modified the brackets that were holding the catch can hose over the intake manifold,

i made holes that were threaded to avoid stupid nuts,

and cut them so the clamp would sit outside while beeing block from rotating,

the brackets were bent inward so that the hose would touch and be completely parallel,

------------------------------

and something much much more interesting,

i bought new tires for summer 2011,

i had used Falken Azenis and Yokohame Neovas in the past,

the Falken sucked in the rain and didn't stick enough, got greasy when really heated,

on the other hand the Neovas were incredibly grippy, but wore way too fast and cost a fortune

i was looking to get tires in the same "max" performance category, in the 275/40/r17 size

my choice would finally come between the Kuhmo XS and the Dunlop Star Spec

both had been proven great track tires and cost relatively the same thing (then),

but from what i heard from auto-x guys is that the Star Spec had really stiff sidewalls,

which would be great for setup where the tires would be stretched outward (narrower wheel like me)

and reading many many reviews online, i came to the conclusion that the Dunlop wore less and were better in the wet,

better road tires in general

on the downside, the Dunlops were only available in 265/40/r17

but i was ready to let it pass for good tires

the best quote i got in canada for a set of 4 tires was ~1400$ tax inc (friendly price too!)

i ended up buying them from the USA from Tirerack at half the price,

but to avoid the huge brokage/shipping costs,

i had them shipped to a warehouse just on the other side of the border in New York state,

all i had to do was drive down there, cross the border, go to the warehouse 1km away and pay a certain fee,

i think it was 8$ per package (then) and i had 2x2, so 16$

heres me picking them up..... yeah they do ALOT of tires for canadians;

then cross the border back into canada WITH the invoice,

go inside and manually pay the taxes and brokage fees (7% for japanese made)

and get back home

calculating the cost of the tires, shipping inside the states, warehouse fees, taxes, brokage fees, and even gas, it cost me 950$ in total, a 450$ saving

and... i got back home within 2 hours !

(the border gates were completely empty on a thursday evening, both ways)

Dunlop Direzza Z1 Star Spec 265/40/r17

my new tower of power

the threads are so agressive and deep, great for evacuating water !

so thats it for week no6

the interior is done, next up is some more exterior carbon mods

more info in the week 7 update

stay tuned !!

thanks for readingLast edited by frankiman; 03-19-2012, 11:19 PM.

Comment

Comment