Chapter 46 - So fresh and So clean

week9 – 2011, part 1/2

disclaimer :

the following story depicts actions that occured between June 29 and july 5 2011

information is recalled purely from memory, give me a chance

if you've read the last chapter, you know i had taken off all 4 wheels for no apparent reason..

well no, i took them off to get them re-painted (3rd time) and mount the new tires on,

so one night i packed my dad's 4x4 with 8 tires total;

the place where i was getting them painted was a 40 min drive from home, but in summer 2011 i had an engineering internship 60 minutes away, in the same direction

and that place closed as early as 5pm

so i took the 4x4 and stopped there on my way home after work, just before 5pm,

explained them which tires to put where and what type of paint job i wanted, this time

my phone was dead so i asked the secretary to take a picture and send it by email

this was to see the difference in total height (width) of the new and old tires;

meanwhile, i got something else done...

i really wanted center caps for my wheels because the axle nut was ugly as fawk,

but Work doesn't make any center caps for the Emotion CR Kai wheel, every other emotion yes, but not the CR Kai

and after mucho searching on the web, i didn't find anything anyone had done to make some for those wheels

and.. i didn't want to modifiy the wheel to be able to receive center caps and hold them on tight,

so since the GTR is AWD, it has 4 axles, thus 4 axles nuts/threaded shafts, each identical

why not just make something that would screw over the axle nut heh?

so using high tech measuring tools, i found the thread to be M24x2 (i think, only going from memory here...)

so using a wheel, i decided on the best dimensions for the center cap to come flush with the wheel and cover most of the wheel bore without affecting the removal/install of wheel spacers

this was the first prototype;

the slot in there to be able to screw on/off the caps with a tool (a 1/8" x 2" steel plate)

the caps are made of aluminium, CNC machined the exact specs of my drawings

p.s. i no longer have the drawings for the caps since my computer pooped itself not long after, mid summer 2011, and i lost everything

this is how it would be mounted,

screwed directly onto the axles, with a diamter smaller than the hub, not to interfere with the spacers;

and how it looked with a wheel on;

but since i have different offset wheels and width spacers front / rear, the dimensions would be a bit different for the rear wheels to fit properly

and i had them all painted at the same time as my wheels, the same color;

(2 front + 2 rear + 1 spare front)

and picked up my freshly painted awesome looking wheels;

one thing i was really anal about was the inside finish, because they usually left the insides on the wheels in a rough finish, even powder coated wheels,

but with all brake dust the wheels saw from track time and street driving, it got into the paint and was impossible to clean off

so i asked for a special 'as smooth inside as outside' paint job

which i got for a certain extra, but i'm REALLY glad to have it;

tested the look with the as-well-freshly painted nuts;

all of it on the car;

and the aforementionned tool;

then i put a coat of PoorBoy's wheel scealant inside the wheels, to keep the brake dust from sticking,

those with some detailling knowledge will certainly cringe from seeing the following picture, since i was later told i had used about 10000% too much;

then i fooled around with an industrial paint marker that i got from work, to fill the lettering on the tires,

i did it only on the inside too see how it would look, but for importantly if it would hold;

the then stance...

lets just say that putting 265 tires of a 9" wide rims, makes it look like balllloooons;

but the flushness is perfectly perfect;

but now the tires had a bit bigger diameter, and with a messed up still aligment (my mistake) i was having issues clearing the wheel wells;

--------------------------------

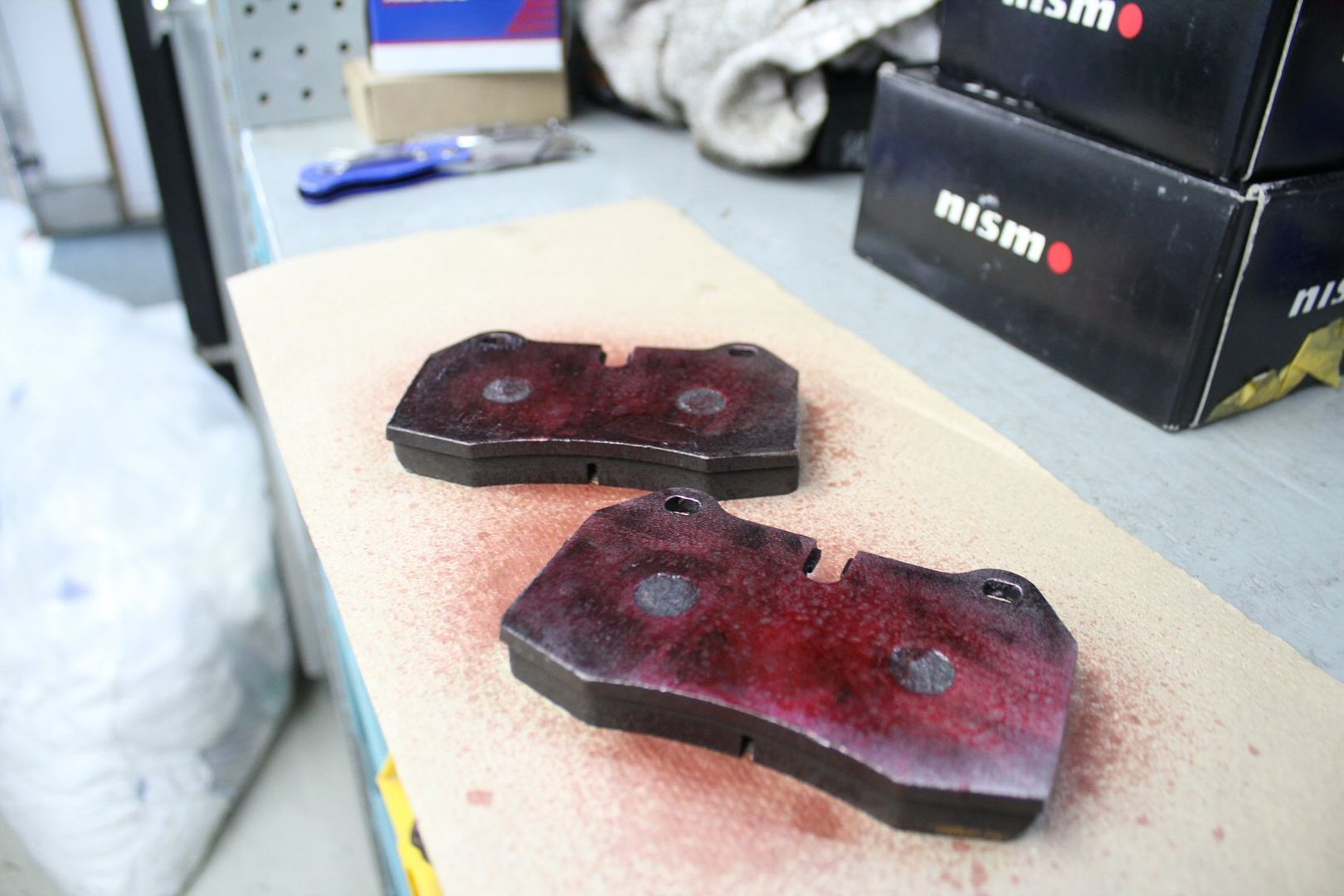

then i moved on to swapping my brakes back from the stock pads to finish the last season

lets just say i have alot of spare pads;

this is the stock BCNR33 pads i got from Daryl which i used at the end of the last season (2010)

i don't know exactly the reason why its beveled that way, but theres only about 2/3 of the surface beeing used ;

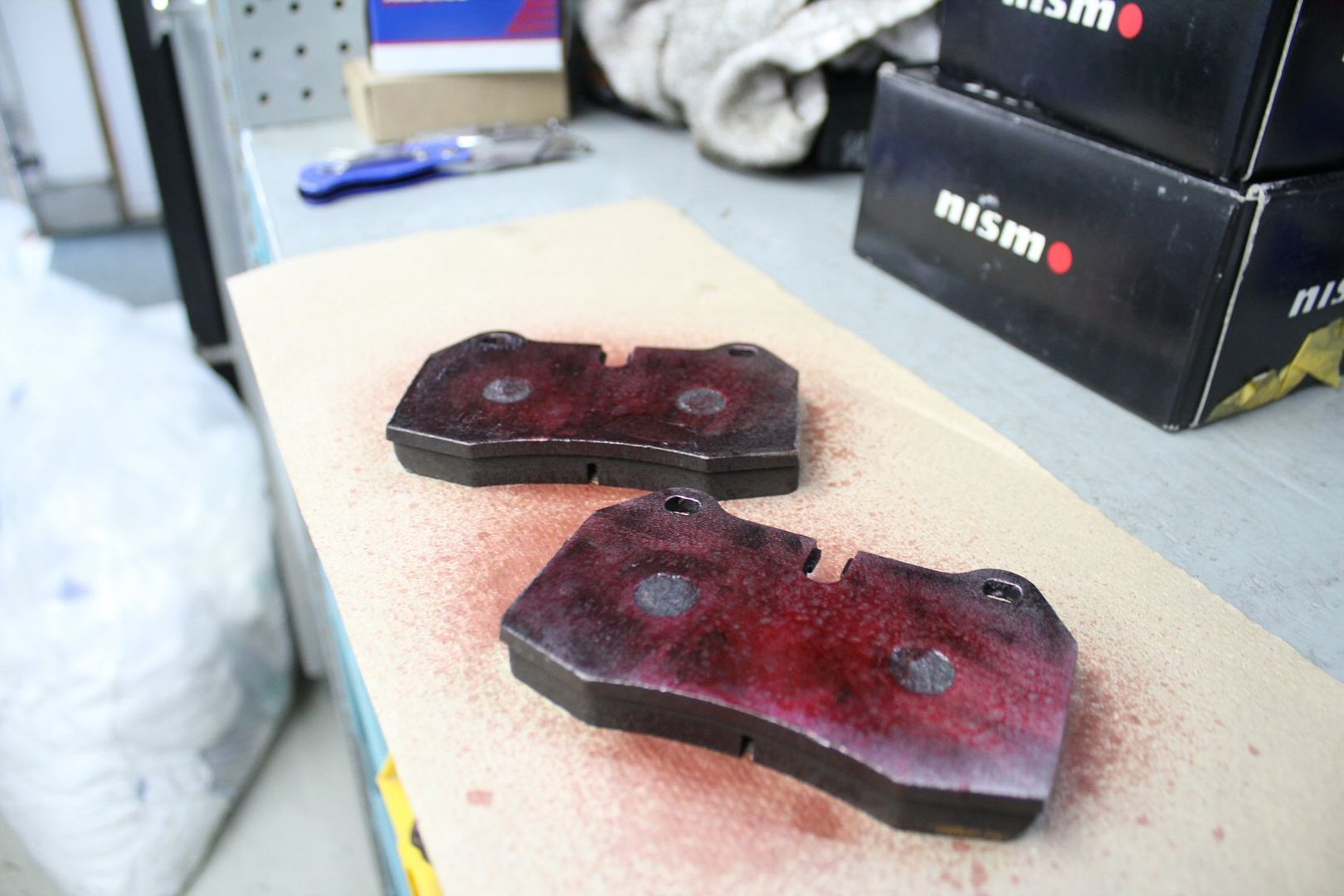

for some reason i was having interference issues between the new Hawk HP+ pads and the powdercoat inside the calipers,

i had to grind down the edges to make it slip in easily, from this;

to this ;

then i enlarged the holes on my custom pad shims to make it easier to work with them ;

and gave the new HP+ pads a nice coat of Anti-Squeak ;

part 2 follows...

week9 – 2011, part 1/2

disclaimer :

the following story depicts actions that occured between June 29 and july 5 2011

information is recalled purely from memory, give me a chance

if you've read the last chapter, you know i had taken off all 4 wheels for no apparent reason..

well no, i took them off to get them re-painted (3rd time) and mount the new tires on,

so one night i packed my dad's 4x4 with 8 tires total;

the place where i was getting them painted was a 40 min drive from home, but in summer 2011 i had an engineering internship 60 minutes away, in the same direction

and that place closed as early as 5pm

so i took the 4x4 and stopped there on my way home after work, just before 5pm,

explained them which tires to put where and what type of paint job i wanted, this time

my phone was dead so i asked the secretary to take a picture and send it by email

this was to see the difference in total height (width) of the new and old tires;

meanwhile, i got something else done...

i really wanted center caps for my wheels because the axle nut was ugly as fawk,

but Work doesn't make any center caps for the Emotion CR Kai wheel, every other emotion yes, but not the CR Kai

and after mucho searching on the web, i didn't find anything anyone had done to make some for those wheels

and.. i didn't want to modifiy the wheel to be able to receive center caps and hold them on tight,

so since the GTR is AWD, it has 4 axles, thus 4 axles nuts/threaded shafts, each identical

why not just make something that would screw over the axle nut heh?

so using high tech measuring tools, i found the thread to be M24x2 (i think, only going from memory here...)

so using a wheel, i decided on the best dimensions for the center cap to come flush with the wheel and cover most of the wheel bore without affecting the removal/install of wheel spacers

this was the first prototype;

the slot in there to be able to screw on/off the caps with a tool (a 1/8" x 2" steel plate)

the caps are made of aluminium, CNC machined the exact specs of my drawings

p.s. i no longer have the drawings for the caps since my computer pooped itself not long after, mid summer 2011, and i lost everything

this is how it would be mounted,

screwed directly onto the axles, with a diamter smaller than the hub, not to interfere with the spacers;

and how it looked with a wheel on;

but since i have different offset wheels and width spacers front / rear, the dimensions would be a bit different for the rear wheels to fit properly

and i had them all painted at the same time as my wheels, the same color;

(2 front + 2 rear + 1 spare front)

and picked up my freshly painted awesome looking wheels;

one thing i was really anal about was the inside finish, because they usually left the insides on the wheels in a rough finish, even powder coated wheels,

but with all brake dust the wheels saw from track time and street driving, it got into the paint and was impossible to clean off

so i asked for a special 'as smooth inside as outside' paint job

which i got for a certain extra, but i'm REALLY glad to have it;

tested the look with the as-well-freshly painted nuts;

all of it on the car;

and the aforementionned tool;

then i put a coat of PoorBoy's wheel scealant inside the wheels, to keep the brake dust from sticking,

those with some detailling knowledge will certainly cringe from seeing the following picture, since i was later told i had used about 10000% too much;

then i fooled around with an industrial paint marker that i got from work, to fill the lettering on the tires,

i did it only on the inside too see how it would look, but for importantly if it would hold;

the then stance...

lets just say that putting 265 tires of a 9" wide rims, makes it look like balllloooons;

but the flushness is perfectly perfect;

but now the tires had a bit bigger diameter, and with a messed up still aligment (my mistake) i was having issues clearing the wheel wells;

--------------------------------

then i moved on to swapping my brakes back from the stock pads to finish the last season

lets just say i have alot of spare pads;

this is the stock BCNR33 pads i got from Daryl which i used at the end of the last season (2010)

i don't know exactly the reason why its beveled that way, but theres only about 2/3 of the surface beeing used ;

for some reason i was having interference issues between the new Hawk HP+ pads and the powdercoat inside the calipers,

i had to grind down the edges to make it slip in easily, from this;

to this ;

then i enlarged the holes on my custom pad shims to make it easier to work with them ;

and gave the new HP+ pads a nice coat of Anti-Squeak ;

part 2 follows...

aint head lights

aint head lights

Comment