Announcement

Collapse

No announcement yet.

Caliber's R32 GTR Project

Collapse

X

-

Really cool build dude, are there any updates? Keen to see the rims if you've managed to get them on?

-

Just a teaser of the carbon kevlar endeavour. The interior trim is to come. Mass ordering parts so they should be pouring in in the next few weeks hopefully to kick it into high gear.

Leave a comment:

-

The battery holder is from some off-road company, ballistic fabrication I believe, made specifically for the optima battery, it came unpainted but I covered it in that wrinkle effect paint.Originally posted by tman7878 View PostSick build.

Where'd you get the battery relocation tray? And what did you coat it with?

Leave a comment:

-

I got it off a member here but it's from a company called demon. Search demon surge tank and there should be some on their website and ebay. I like the radium ones but they are more based around twin Bosch pumps.Originally posted by sb119 View PostWhere did you pick up your surge tank from? I was planning to go with a Radium Engineering one but they don't make exactly what I want so I'm looking into other options

Leave a comment:

-

Sick build.

Where'd you get the battery relocation tray? And what did you coat it with?

Leave a comment:

-

Where did you pick up your surge tank from? I was planning to go with a Radium Engineering one but they don't make exactly what I want so I'm looking into other options

Leave a comment:

-

So I got all the carbon kevlar supplies to start overlaying things so let's hope it goes well. Here's the kevlar fabric, it's the closest I could find to the bride kevlar seat pattern. I'm expecting it'll darken up with the epoxy resin.

And about half way through the partial wire tuck, adding some remote jump posts in the engine, used some Audi parts as everything aftermarket looked like junk. It'll make jumping and charging much easier. The insulated positive box and there's the negative post by the strut tower bolt, placement is to be decided

Leave a comment:

-

Holy $hit that set up looks great! Both the surge tank/pump and turbo plumbing.

Leave a comment:

-

Yeah thats a pretty small area to work with for hard lines. Gold AN fittings look good!

Leave a comment:

-

So a small update, seems to be what they are now.

I had to scrap the hardlines between the pump and surge tank, couldn't make it fit whichever way I made it. So some flex lines later and it fits perfect and looks decent IMO,

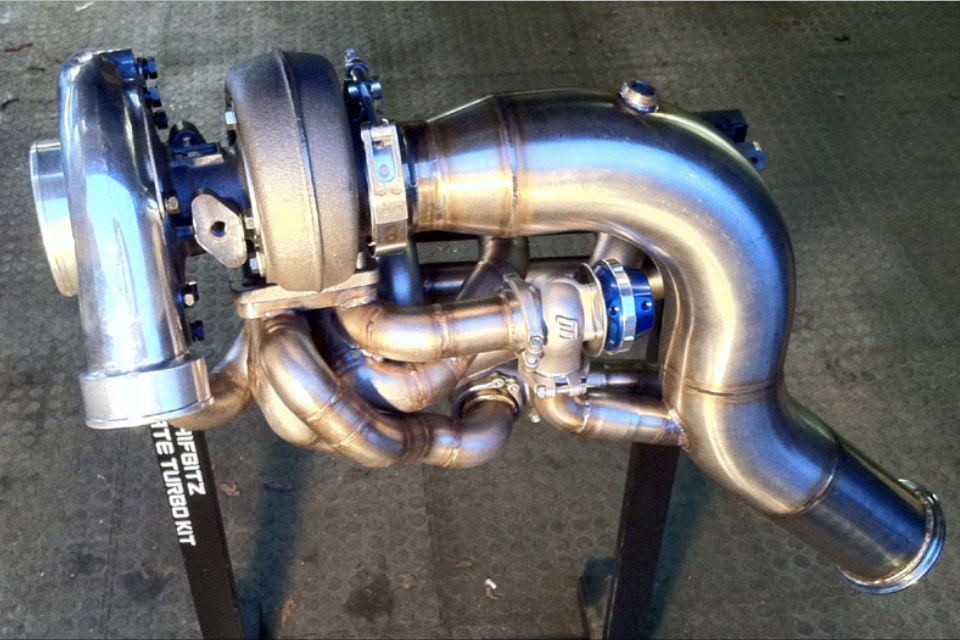

Also finally bought a project whifbitz twin scroll manifold , downpipe, and mid pipe after saving for a while. I chose this manifold as it's the only one that has the option of recirculating the wastegates back into the exhaust. Anyways owner said its a three week wait to make, here's what I can look at in the time being

Last edited by caliber676; 02-12-2014, 03:30 AM.

Last edited by caliber676; 02-12-2014, 03:30 AM.

Leave a comment:

-

^ you must be mistaken, the hardlines pictures above are for fuel not the brakes. You are correct though, you shouldn't be using anything but the approved double walled tubing for brake lines with the approved ISO/ bubble flares

Imagine using though -8an lines for brakes lolLast edited by caliber676; 02-07-2014, 12:07 AM.

Leave a comment:

-

Are you sure you should be using aluminum piping for brake lines? "Brake lines should always be fabricated from Bundy tubing having a wall thickness of 0.028" minimum. Brake line pressures can and do exceed 1000 psi. On no account should copper, aluminum, or commercial fuel line be used, despite the fact that they are easily available and appear to be easy to work with. Pure copper tubing work-hardens and becomes very, very brittle- especially at flare fittings. Under the cyclical loadings seen from brake applications, and in the presence of moisture (and possibly high concentrations of chlorides, if you live in a road salt area), they will almost certainly fail. They will tend to crack and fail right at the flare, generally with little or no warning. (Copper also catalyzes the auto-oxidation of fuel, the mechanism of sludge formation. Copper should never be in contact with fuel.)" quoted off the Internet from a quick google search. Are these lines certified to be used as brake lines? Just curious.

Leave a comment:

-

Leave a comment: