TTBB Oil Cooler Project ( Pics, Ideas & Experience )

The purpose of my threads is not to show off but to make some designated people think and create ideas for themselves and many different communities with hope that they come back with better ideas and even more cleanlier explanations.

May be some people will find this information useful or maybe use some of the ideas from this thread on their own projects...

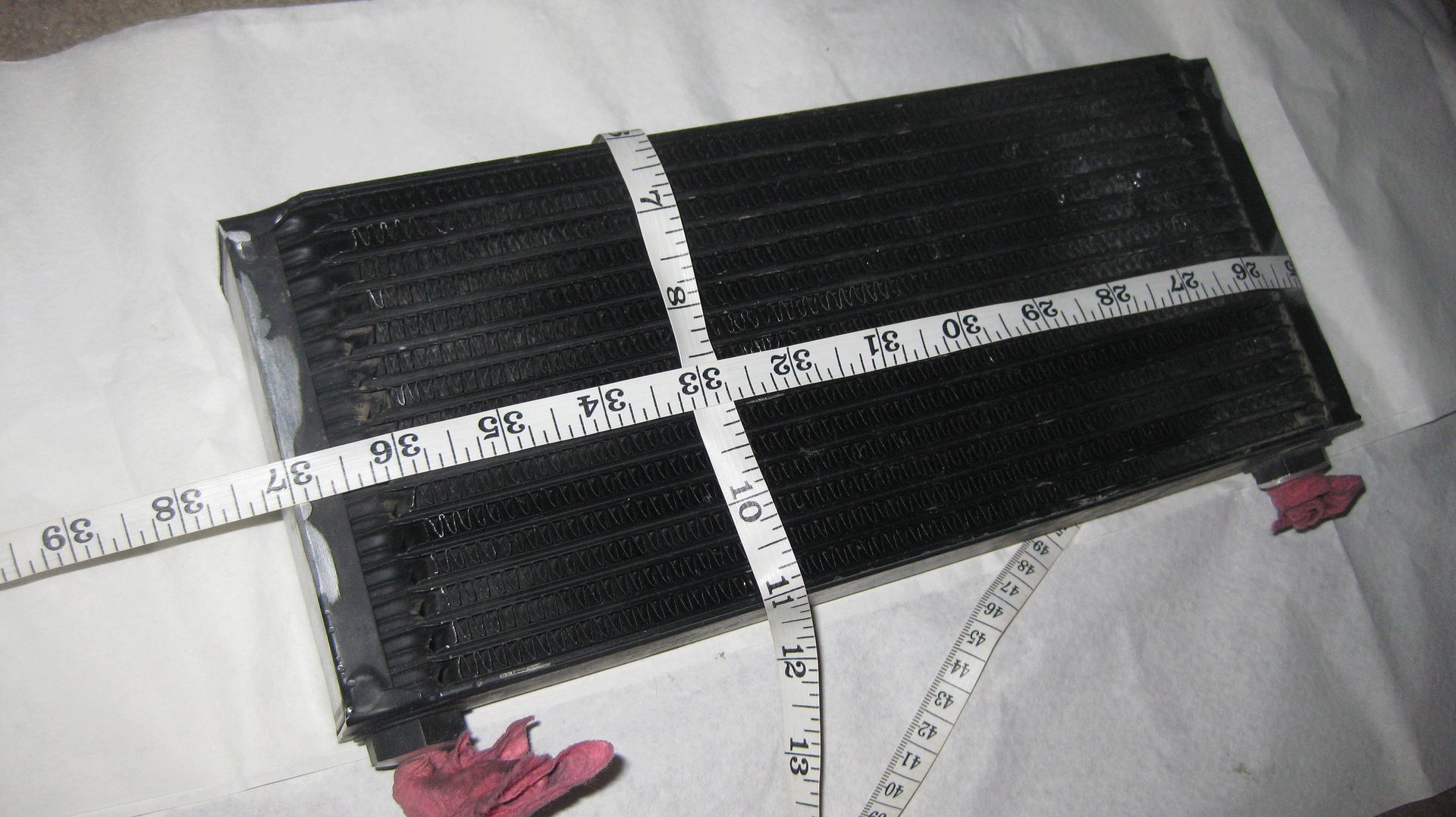

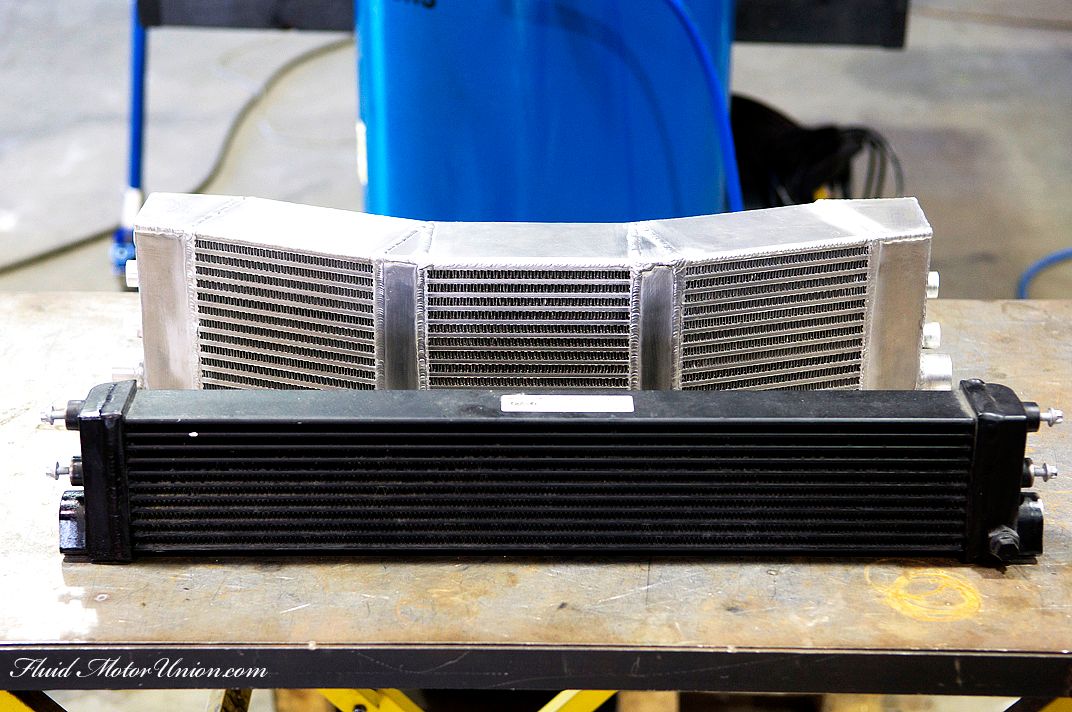

Here it is, there is many different types and brand of Oil coolers but ive decided to stick with OEM, so, here is the Oil cooler choices I had. Top to bottom:

Saab 9000 2.3 Factory Oil Cooler

Ford F150 OEM Transmission cooler

HUGE RX7 Stock Oil Cooler

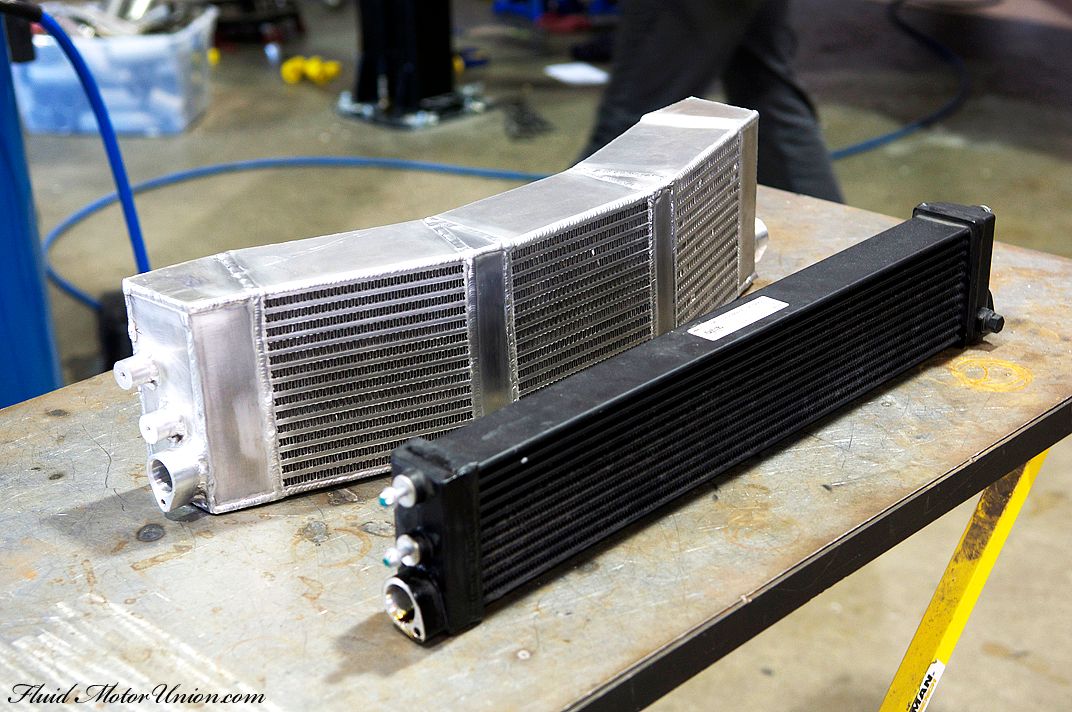

The one on the right is a variant of the smaller F150 tranny cooler:

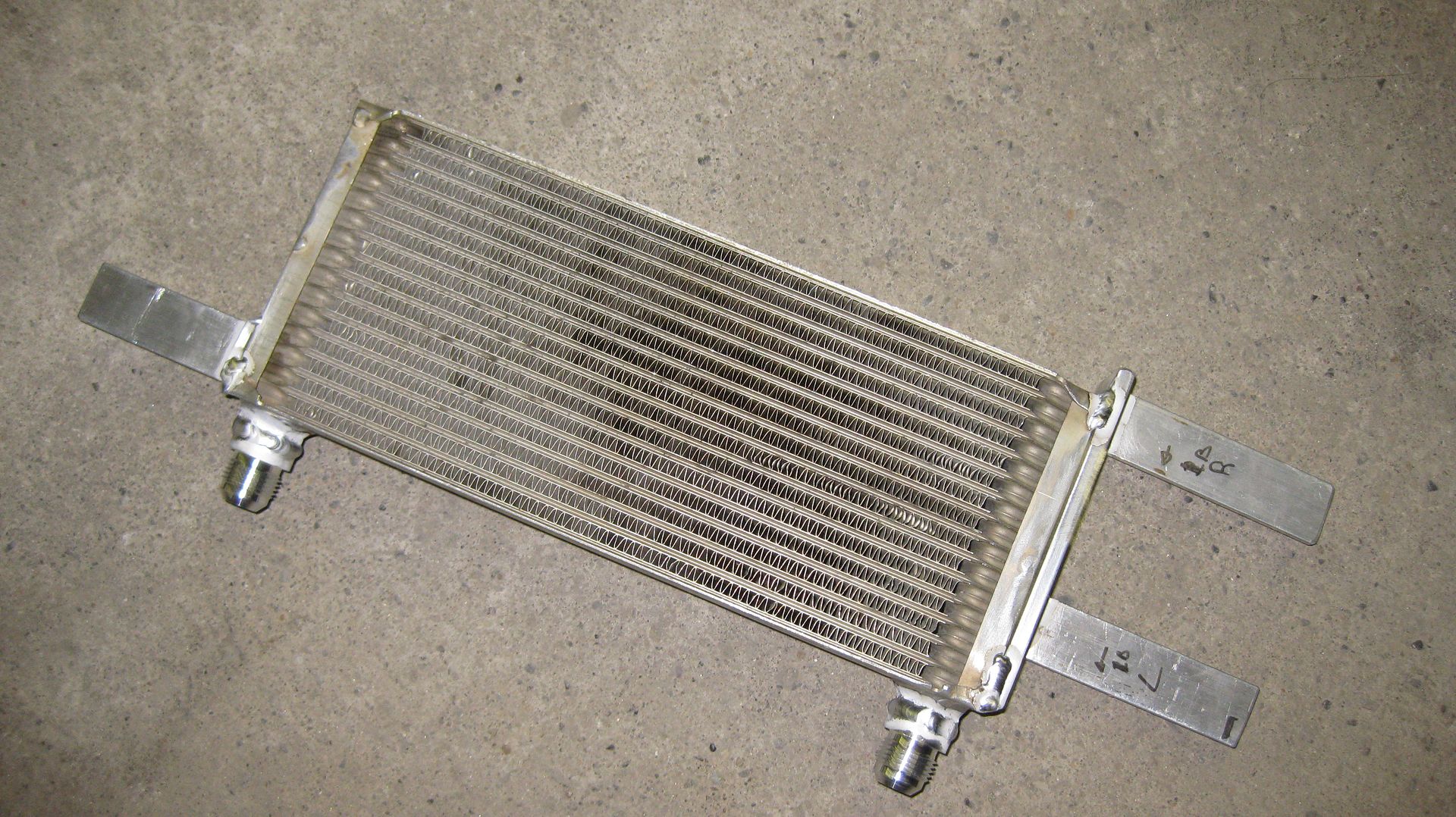

But the RX7 oils cooler looked overkill with its dimensions and thermostat, they must be running some sort of oversize oil pump just to support this size of oil cooler.

The 300zx TT looked really small:

So I used Saab 9000 2.3 Turbo cooler and it seems to be working great for the last few years:

Dimensions

Thickness

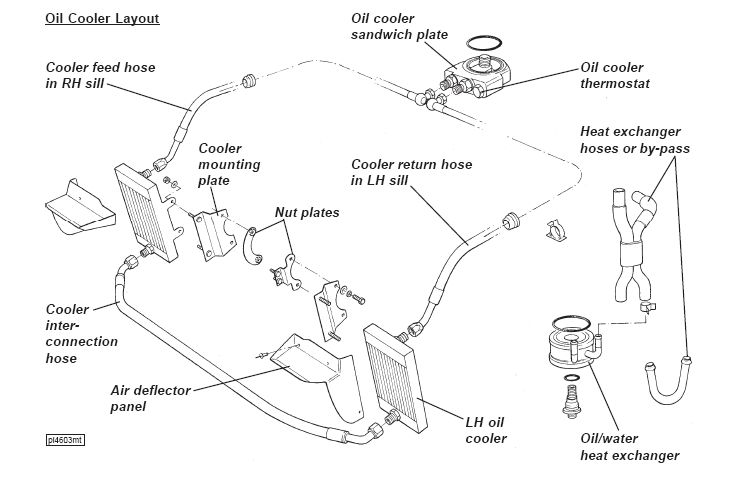

I welded -10 bungs and some straight pieces of aluminium arms to connect cooler solidly in the space in front of my AC rad and between hood hinge and AC Dryer thing (will remove my AC soon)

Im not sure if there has to be P/S lines somewhere there or not, I reroute my lines, when I did Hicas elimination, that there is no power steering loop for cooling!

The connectors that holds the -10 lines together and prevent hoses from wobbling around are from some kind of Ford Focus coolant lines.

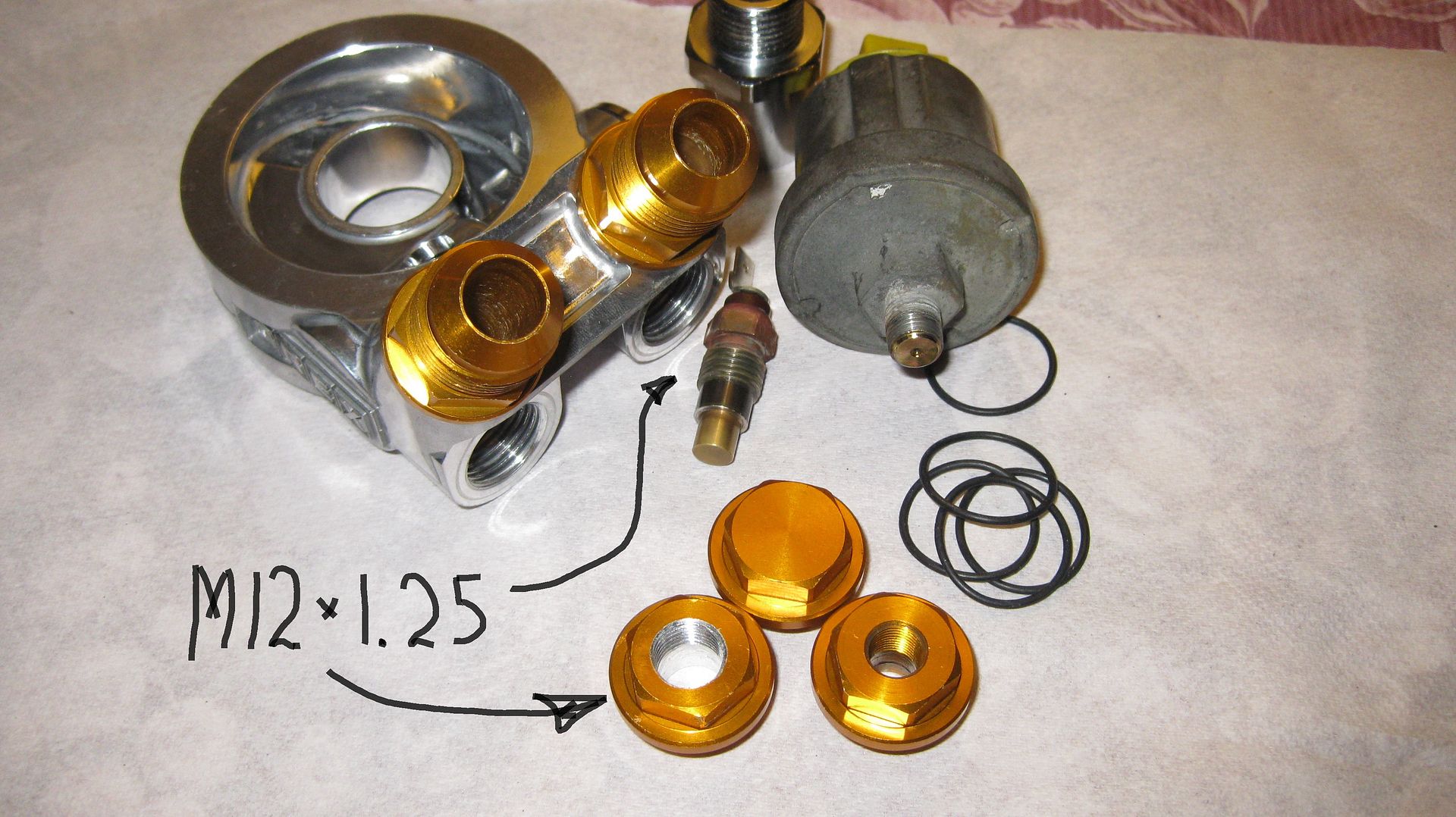

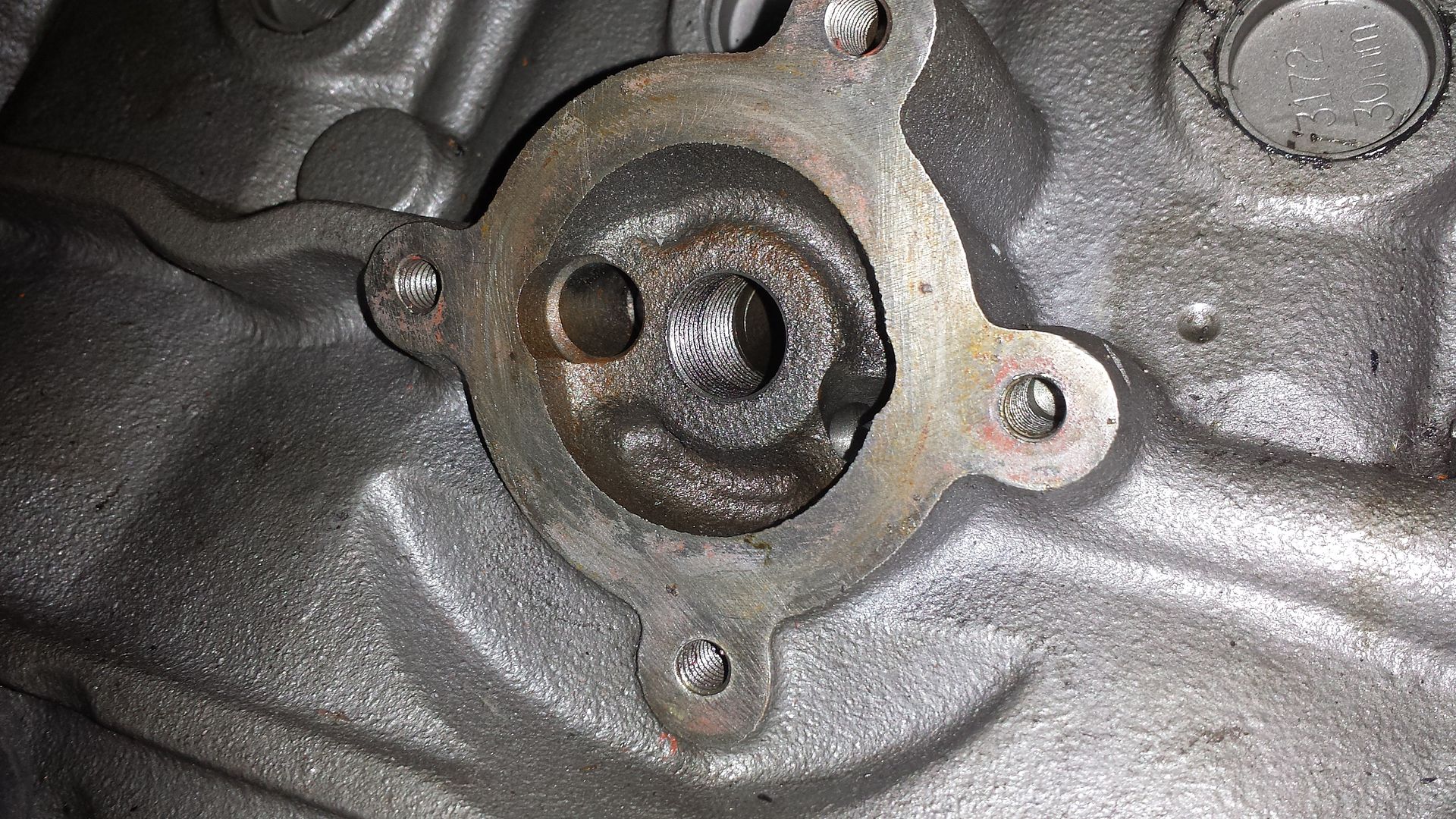

Next is I removed the oil to water heat exchanger, which I think is a completely useless thing IF, you are using proper oil cooler and install "Raw Brokerage" (Link might die with their site upgrade) filter to block stud! You can also find similar stud on very old Datsuns:

Of course i wanted to keep both Pressure and Temperature gauges working on the dash so I used included cap with 1/8 NPT for Oil pressure sending unit and I had to drill and Cut one cap for oil temp sensor:

Comment