Looks good man.... Like the gauge setup.

Announcement

Collapse

No announcement yet.

Project mexi skyrine ver.2

Collapse

X

-

wasnt gonna update but i washed it tonight for this weekend and realized i dont have any pics of it actually clean.

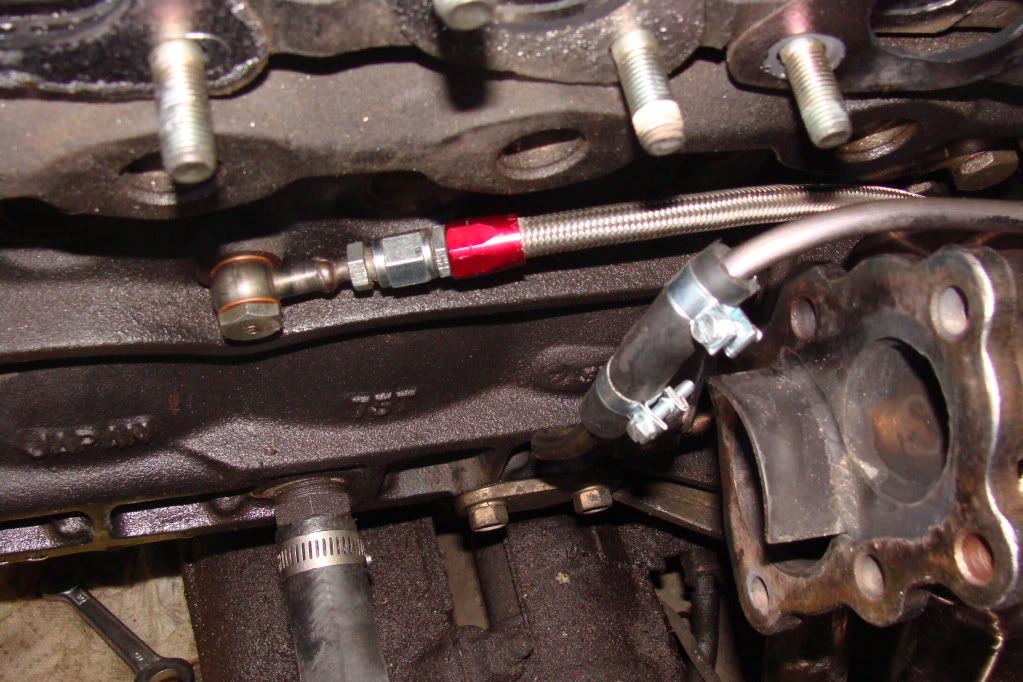

just for you ppl who said my wideband o2 was too close. it is now 15" or so away from turbo.

RB25 Powered RWD GT-R

RB25 Powered RWD GT-R

Owner for Turtle Garage Hicas Delete Systems

Comment

-

had a blast at round 1. froze on saturday and burned on sunday. also hardparked like a boss.

went on macleod and took a pic randomly

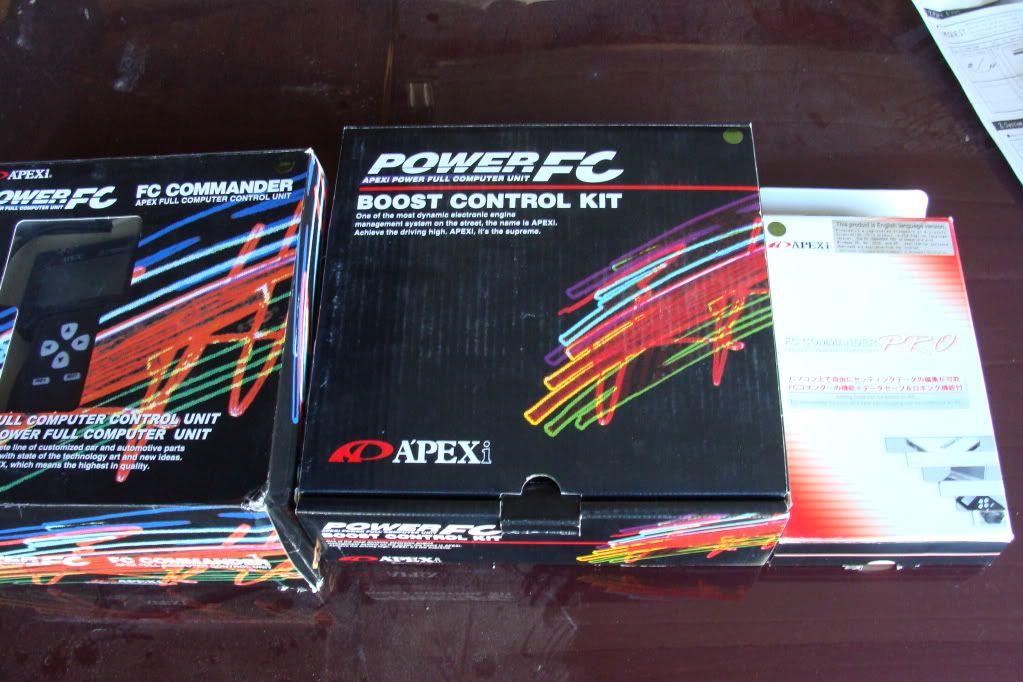

and got my power fc. thanks to jason delehay for it and cody duthie for bringing it for me.

The fun begins now! RB25 Powered RWD GT-R

RB25 Powered RWD GT-R

Owner for Turtle Garage Hicas Delete Systems

Comment

-

finally an update.

bought myself a:

Holset HY35 turbo

top mount mani

38mm wastegate with sceamer pipe

all 3" stainless for dp

aluminum intake pipe with new couplers

10 row oil cooler

also ordered:

660cc injectors

Q45 throttle body

Z32 maf

tomei fuel pressure regulator

k&n air filter

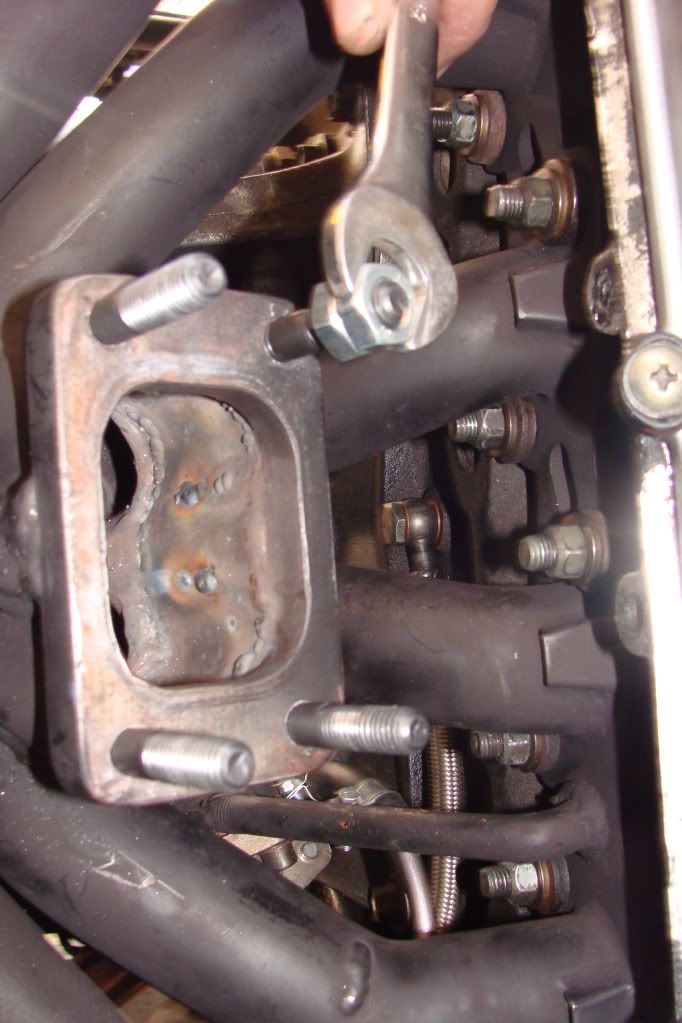

took off the stock crap. and as everyone does i broke one of the studs.

good ol easy out.

got the coolant return and oil feed done

had to get the manifold rewelded as the turbo didnt fit

then painted it with high heat flat black paint.

well lookey here the stock oil drain pipe works perfect

also heres where i mounted my commander

and best for last i got the manifold and turbo together for the final test fit.

was also trying to figure out some i/c piping

RB25 Powered RWD GT-R

RB25 Powered RWD GT-R

Owner for Turtle Garage Hicas Delete Systems

Comment

-

update. got lots of stuff. still waiting on more.

list of stuff thats in the picture:

Intercooler piping: (all aluminum)

-2 3" 90 degree bends

-1 3" 180 degree bend

Exhaust: (all stainless)

-1 3" 90 degree bend

-1 4"-3" reducer

-1 3" flex pipe

-1 3" v-band set

-1 4" v-band set

-1 vibrant o2 bung

Greddy type r bov

oil cooler

660cc injectors

Q45 throttle body

aluminum intake pipe

z32 maf

bunch of fittings for catch can and oil cooler

Ok so for the first step this weekend. catch can

catch can parts list:

-1 3/4"npt pipe tap

-1 1/2"npt pipe tap

-2 3/4"npt to -12an 90 degree fittings

-4 -12an straight fittings

-2 -12an 90 degree fittings

-1 -12an weld bung

-3 -12an to 1/2"npt straight fittings

-2 meters of -12 nylon braided line

ok started off taking off the valve covers and threaded the back with the 3/4"npt pipe tap i bought then installed and Teflon'd the 3/4"npt to -12an 90 degree fittings

the 1/2"npt is one the right and 3/4"npt is on the left. these were not cheap to buy.

then started working on the catch can

drilled 3 holes and threaded with the 1/2"npt tap

teflon teflon teflon

bolted into place

i didnt have any washers so i figured 50yen would do

and now for the lines. man they were a ******* curse. i had to tape them and hold on to the nylon braided so it didnt slide down the hose when putting on the fitting. and oh ya i had to hold the tape with my teeth and push on the red part with my hands (ill post pics of the next one if you want)

heres most of the fittings:

one end on

taped the line with packing tape and checked where to cut:

cut the hose with hose cutters i bought

does a sexellent job of doing so. shows buying the right tool is best

one complete hose done

boom an hour later and second hose done

-12an weld bung gets welded here

and eventually will be connected as so (after welding)

that sums up today much more to come

pics of q45 throttle body and hot side piping

RB25 Powered RWD GT-R

RB25 Powered RWD GT-R

Owner for Turtle Garage Hicas Delete Systems

Comment

-

ya cant wait. i would like to drive it at sunday funday with just stock injectors. maybe make it a 2 day and get it tuned the saturday beforeOriginally posted by Supraclean View PostLiken the updates man, just checked it quick on the phone. Engine gets mad style/ taste points from me.

Also good choice on the fancy yet functional catch can setup, really sets it off.

Getn excited for tune with this thing or what? doubt it will be ready tho. alot of welding to be done still

RB25 Powered RWD GT-R

doubt it will be ready tho. alot of welding to be done still

RB25 Powered RWD GT-R

Owner for Turtle Garage Hicas Delete Systems

Comment

-

update.

exhaust and turbo weekend.

so i finally arranged a full day with my cousin (welder) and we got my exhaust built.

after roughly 8 hours of fabbing and welding this is what we got

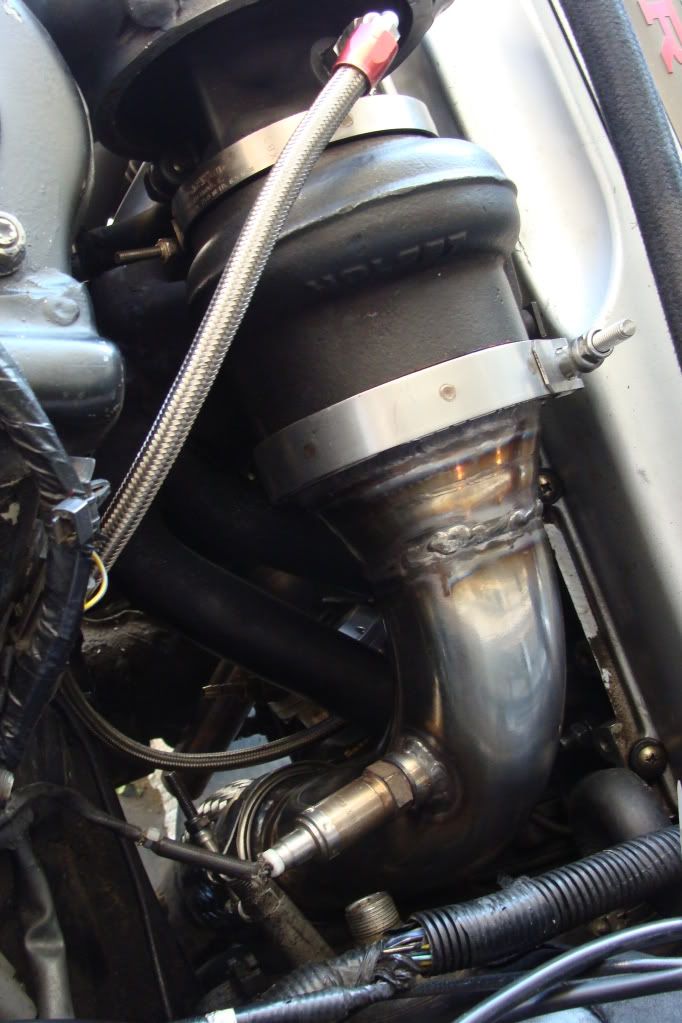

turbo elbow downpipe and screamer pipe all stainless all tig welded

now that those were made it was time to finally bolt down everything related to turbo

no pictures of the manifold to head gaskets but they are all new and sprayed with copper gasket all bolted down safely

next was new studs for the turbo. using two nuts they tightened up nice.

picture of the copper gasket spray i used. also the high heat gasket maker for the oil drain.

all sprayed up and ready for the turbo. had to cut one of the studs to clear the turbo

gasket maker on

painted with high heat paint and bolted up

turbo bolted on. new nuts and lock washers too

first v band on

both v-bands on and o2 and wideband o2 in

final pic

next update will be fuel and oil stuffRB25 Powered RWD GT-R

Owner for Turtle Garage Hicas Delete Systems

Comment

Comment