Originally posted by gtrjon

View Post

Announcement

Collapse

No announcement yet.

REIMAX (Collar clearances, pics)

Collapse

X

-

Im sorry,would i be intrested in macining NEW REIMAX GEARS?? - NO; Would i be intrested in Allens collars for reimax gears - Yes. But i think his price for limited collars for Reimax gears would be too high, if he ever do them! In my opinion this is simple task and that shouldn cost any more expensive, unless i repeat unless, your machine or jig is strictly set on producing only stock size collars, and not used for anything else!Originally posted by vaderj View PostI'm in calgary aswell, would you be interested in splitting the cost of getting a few reimax inner gears machined with the proper id to match the long snout crank?

In short words - YES. Because paying... ???, how much did you payed for the new crank? I wouldnt afford! And if you are buying second hand r33 crank you have really good chance to end up with large clearances!Originally posted by gtrjon View Postso after all of this research and these conclusions you are saying there is no point in buying a r33/34 crank and best option is a r32 crank with allens collars if using a oem or n1 pump? correct me if i am wrong.

Besides there is a bunch of other places that sells collars, for example yesterday i found a new ( to me) website "raw brokerage" they sell collars as well, i never tried them but they still might be good (clearancevise). The only 3 ive tried were: Jun, Australian, and Allen, where i found out Allens one being extremelly properly done, with the right tolerances!

My plan is to use this 60k km oil pump with Allen collar, and if hi will not going to agree in prodicing the Reimax spec collars ill probably try to return it back to Reimax through the Feastauto, where i got it from! Because this is BS, i paid $450 for this gearset and it is not even the same as stock/n1 diameter gears!Last edited by tryingtobebest; 03-04-2011, 06:44 PM.

Leave a comment:

-

so after all of this research and these conclusions you are saying there is no point in buying a r33/34 crank and best option is a r32 crank with allens collars if using a oem or n1 pump? correct me if i am wrong.

Leave a comment:

-

I have to disagree with you here! Even though all of this stuff is used, i clearly do not see anything wrong with it!Originally posted by archaeic_bloke View Postcan you measure the diameter of the R33 crank flat to flat?

I wish I had measured my R34 crank then we could have compared! we just need someone to measure a new R34 crank then,

the other possibility is that usually when one metal is softer than another, the hard one, even though only marginally harder, (even different grades of hardened steel) will still deform the softer metal, so if the oil pump gear is harder than the crank itself, it makes sense that these old cranks you measure here are soo much larger clearance wise, because they've been deformed from the original perfect shape!

its just a theory, all that to say we really need someone with a brand new R34 crank and oil pump (oem/N1) to measure those clearances, that would be key!

then we could conclude wether its a nissan engineering fault, or if its just wear on the materials.

EDIT: Actually, looking at the photo you just posted, its 100% obvious that the crankshaft must be made of a softer steel than the oil pump gears! so I would say that truthfully the clearance you are measuring is so bad because thats all used stuff...

we deffinitely need to see what a new crank compares like.

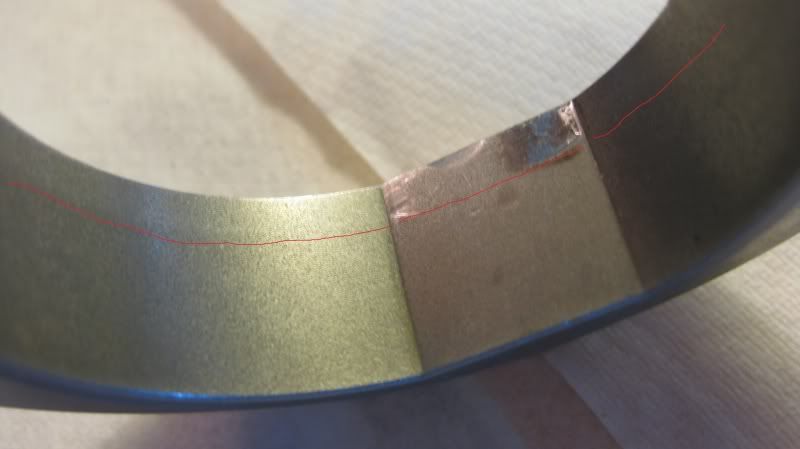

Look at the last picture in the post 18, you clearly see that there is no warpage or some kind of phusical distortion of that perticular oil pump drive, except where the oil pump was hitting. Why was it hitting there?? - Too much wobble since beginning!!!

Post 14, second picture from the end. 90% of the oil pump area ( under the red line) is never even been attached to the crank, which means - brand new condition! Unless you want to phusically or even theoretically prove that that perticular oil pump gear is worn in any whay, in that area!!!!

I can probably use a paint to express myself better on the pictures, since ESL to me! But I strongly belive that someone is understanding me clearly and can chim in!Last edited by tryingtobebest; 03-04-2011, 06:14 PM.

Leave a comment:

-

i have a brand new r34 crank sitting in the back of my gtr right now lol. only thing is dont have my n1 oil pump yet going to be a whille before i get one....

Leave a comment:

-

can you measure the diameter of the R33 crank flat to flat?

I wish I had measured my R34 crank then we could have compared! we just need someone to measure a new R34 crank then,

the other possibility is that usually when one metal is softer than another, the hard one, even though only marginally harder, (even different grades of hardened steel) will still deform the softer metal, so if the oil pump gear is harder than the crank itself, it makes sense that these old cranks you measure here are soo much larger clearance wise, because they've been deformed from the original perfect shape!

its just a theory, all that to say we really need someone with a brand new R34 crank and oil pump (oem/N1) to measure those clearances, that would be key!

then we could conclude wether its a nissan engineering fault, or if its just wear on the materials.

EDIT: Actually, looking at the photo you just posted, its 100% obvious that the crankshaft must be made of a softer steel than the oil pump gears! so I would say that truthfully the clearance you are measuring is so bad because thats all used stuff...

we deffinitely need to see what a new crank compares like.Last edited by archaeic_bloke; 03-04-2011, 05:42 PM.

Leave a comment:

-

I'm in calgary aswell, would you be interested in splitting the cost of getting a few reimax inner gears machined with the proper id to match the long snout crank?

Leave a comment:

-

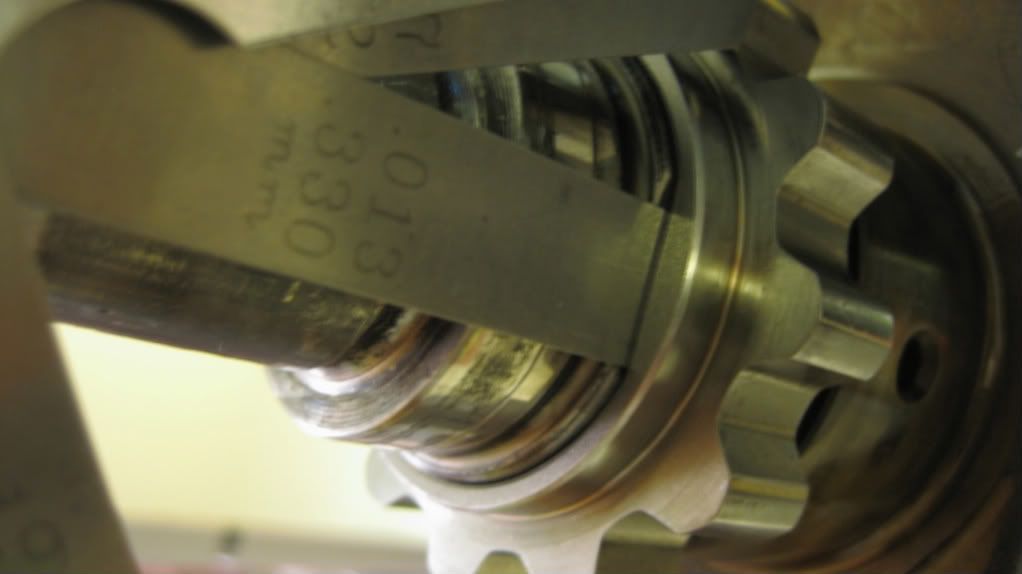

So here is another update withe the measurments of my ~R33 crank! They are not looking very good!

Firs is stock pump gear! .014 and .013 comes to an average ~ .006" on each side - even more than with australian collar! THIS IS CRAZY

Now with Reimax gears - .019 and .018 SO - ~.009 each side! No matter what metal this would be made of they will brake soon or later with this wobble!

In the end i would like to state my opinion, because i see sometimes people are saying that there should be a clearance, if Nissan engeneers did it so there should be one! I would like to say that Nissan almost missed the oil pump with theirs early short oil pump drives, and in the "upgraded" drive they only bend aid this problem extending the drive, so no they didn't pay enough atention in that area and the clearances there should be much smaller than what we experiencing right here!

Leave a comment:

-

Some more info would help this soon the be sticky: diameter (flat spot to flat spot) of inner gear on Tomei, HKS, JUN etc. oil pumps...

and maybe the diameter of the collar its self.

Went to see how those pumps work (eccentric oil pump) Simple!Last edited by GTRADDICT; 03-02-2011, 09:41 PM.

Leave a comment:

-

+1 on the sticky request!! Good show!!! Very Informative, great info.Originally posted by M13 View Postwow, thank you for doing this.

You've just improved the community. Lately, I've been missing this kind of information and maturity on this forum. The immature and useless questions every second thread were making me miss the good ole days. The information you provided with detail, coherency and passion will help many in the future.

Mods, please sticky!!

Leave a comment:

-

wow, thank you for doing this.

You've just improved the community. Lately, I've been missing this kind of information and maturity on this forum. The immature and useless questions every second thread were making me miss the good ole days. The information you provided with detail, coherency and passion will help many in the future.

Mods, please sticky!!

Leave a comment:

-

UPDATE #1

I received a collar from Allen (jdms13rhd) and all i can say is that im very very pleased and impressed with quality, craftmenship and clearances of the collar!

I also received second STD oil pump to doble verify all of the findings!

Here is the beginning, you can see Caliber676's oil pump (he said around 60k km) and GTRBrian's pump (He stated around 80k km was on his)

Here is the first pump (~60k km), as you can see .0015" and .0025", so arond 0.002" each side. Even though that Allen was promising ~.001 each side i think, by the feeling of collar going in and out of the pump inner gear, it almost feels like TOO LITTLE CLEARANCE!!! And when the collar is oing to be pressed on, its going to stretch a little, making the clearances even more tighter!)

Here is the Reimax set! As i was saying before the gear is larger than stock so, here is the specs on it: 0.007" and 0.009" which comes roughly around .008; much much better than my stock R33 cranck!

And in the end, here is another stock pump with ~80k km, as you can see clearances are very very tight! .002 and .0025" so ~ .002 each side which = very very good!

If you guys can see there is a clear image of the old short collar, the part of the drive where tche collar was not touching is like new, so i can say that my measurmens are practically identical to the new pumps!

In the end I would like to thank Allan for doing his research on this problem, ask him to use even more stronger metal in the feauture, if it is possible of course (in order to be bulletproof on international market) and recommend him to decrease inner diameter of the collar by .012 - .025". This, in my opinion will make collar a bit thicker and increase the thickness of the hard working flat spots of collar which make them a little bit stronger.

Thank you Allen

Watch for an update in this thread guys as im going to post some pics of my current crank, and the update after ill install the collar!Last edited by tryingtobebest; 04-06-2013, 10:49 PM.

Leave a comment:

-

are the internal gear and collar the same material? is there a reason an interference fit isn't used?

Leave a comment:

-

ExactlyOriginally posted by derk View Postbeacuse the "fixed" crank still has too much clearance, it has a longer drive, but theres still too much play

^ thats what i gathered from reading this thread anyway

I did a quick measurments of my crank and it looks to be exactly the same diameter as the collar from Australia!

Yes, this way you will know for shure and trust to your oil pump!!! But firstival we should find the collar to be within a specs!Originally posted by GTRADDICT View PostIf this is true... There is no use upgrading to a R33 crank? Just have to fit collar?Last edited by tryingtobebest; 02-27-2011, 09:24 PM.

Leave a comment:

-

If this is true... There is no use upgrading to a R33 crank? Just have to fit collar?Originally posted by derk View Postbeacuse the "fixed" crank still has too much clearance, it has a longer drive, but theres still too much play

^ thats what i gathered from reading this thread anyway

Leave a comment:

Leave a comment: