TTBB BIG Brand Clutch/es Review

In the beginning I want to say that I was madly and deeply in love with OSGiken clutches, I loved everything about them, engineering, construction, longevity and of course price! But since very recently ive order a rebuild kit for my triple plate and was stabbed in the back by my loving one! In this thread I would like to share some of my findings and ideas supported with pictures. All the measurement’s been taken by brand new Starrett caliper and are in millimeters.

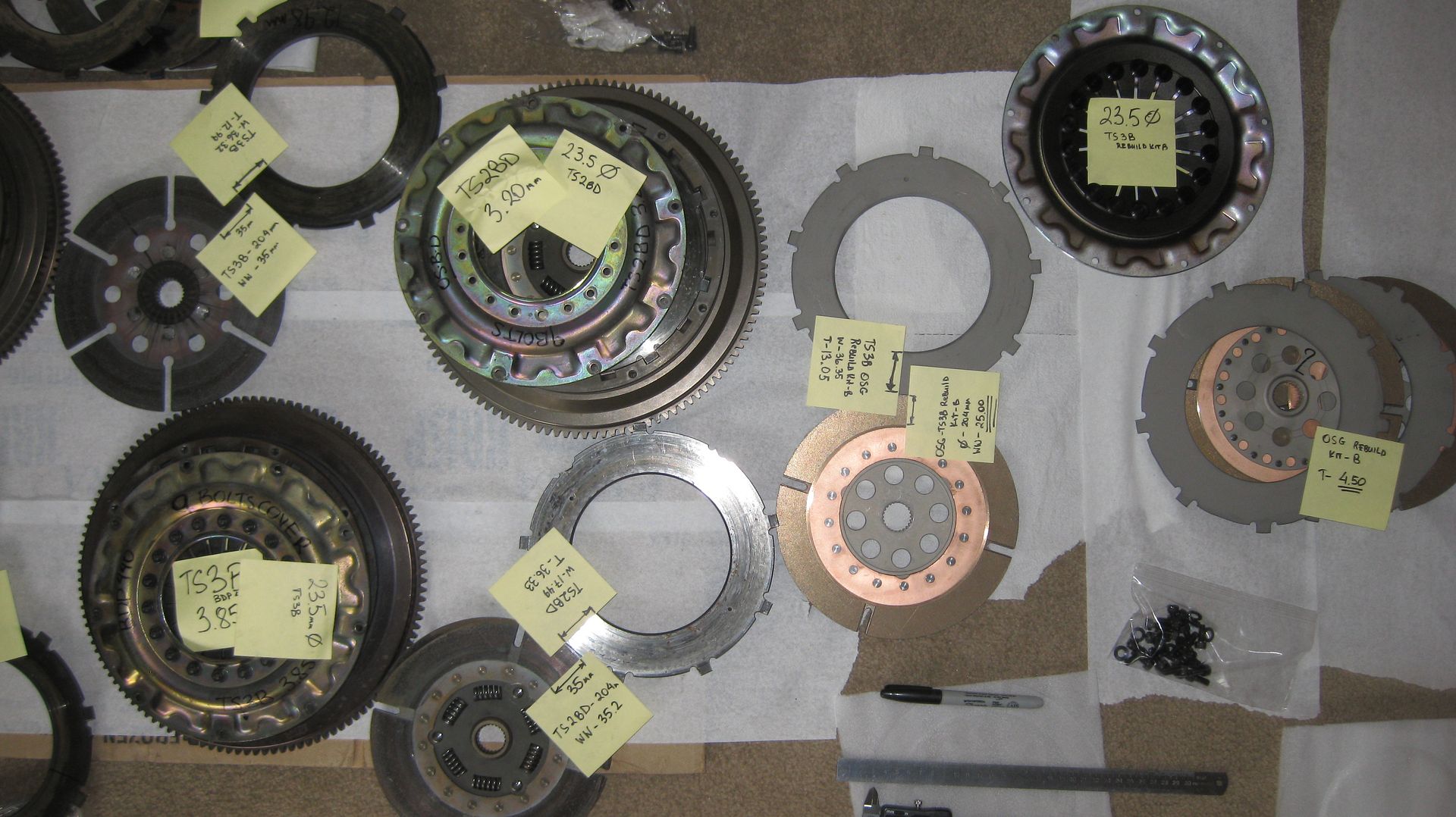

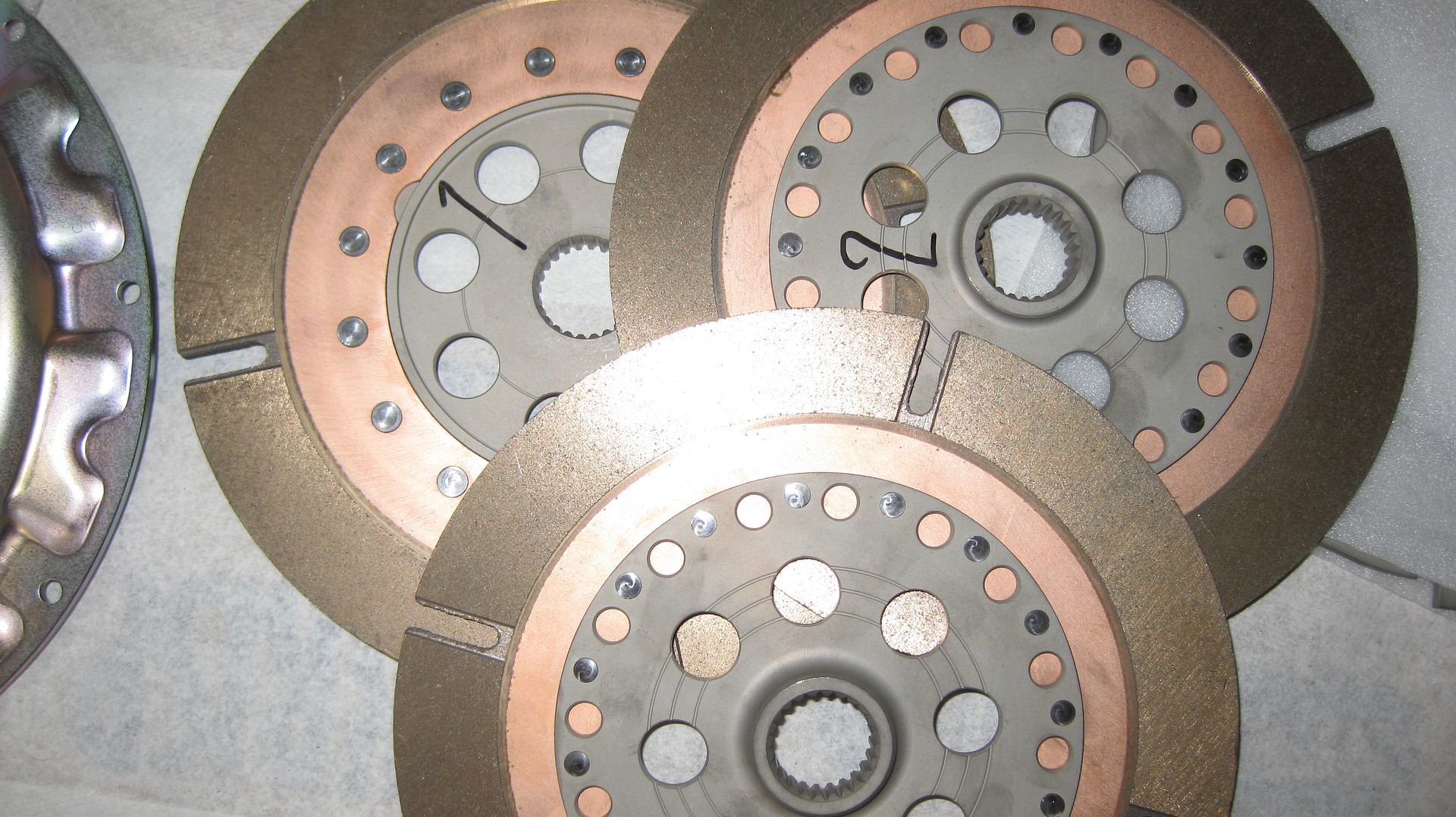

Here is how my ultimate OSGiken clutch comparison test “OLD vs NEW” is looks like! Please try to concentrate on the clutches layout because some pictures ended up being from the side!

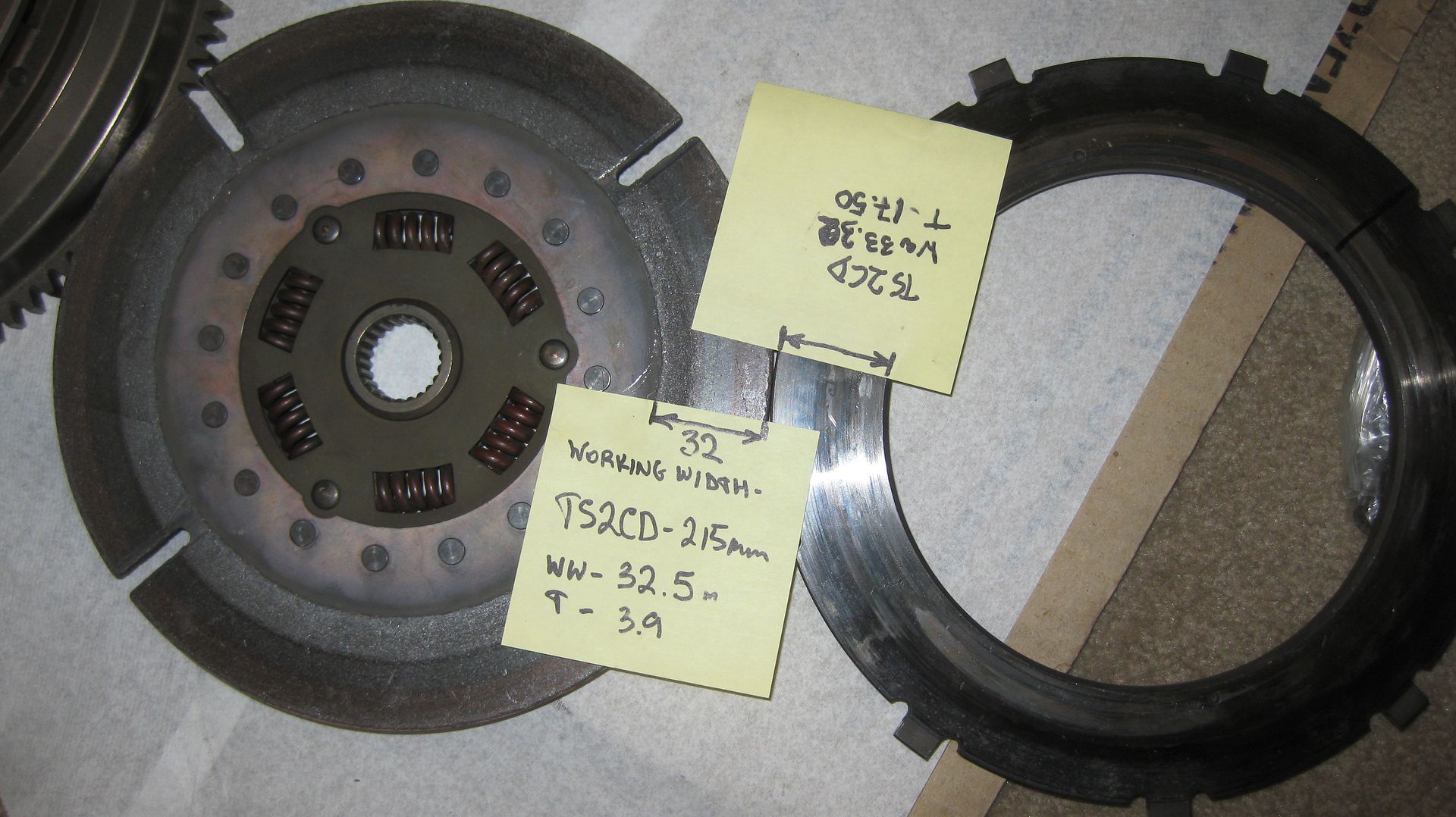

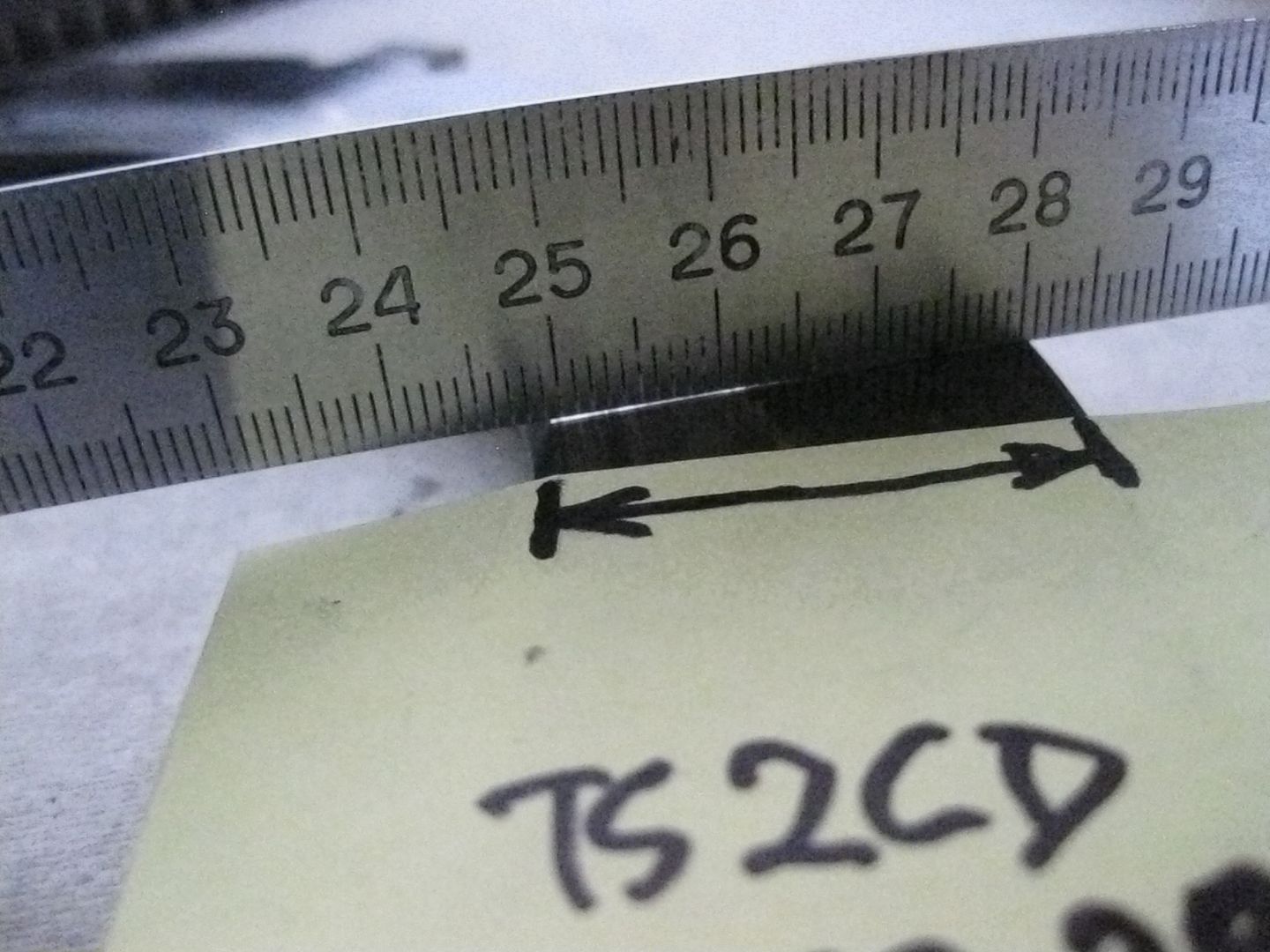

#1 TS2CD (18 bolt cover all the rest are 9 bolts)

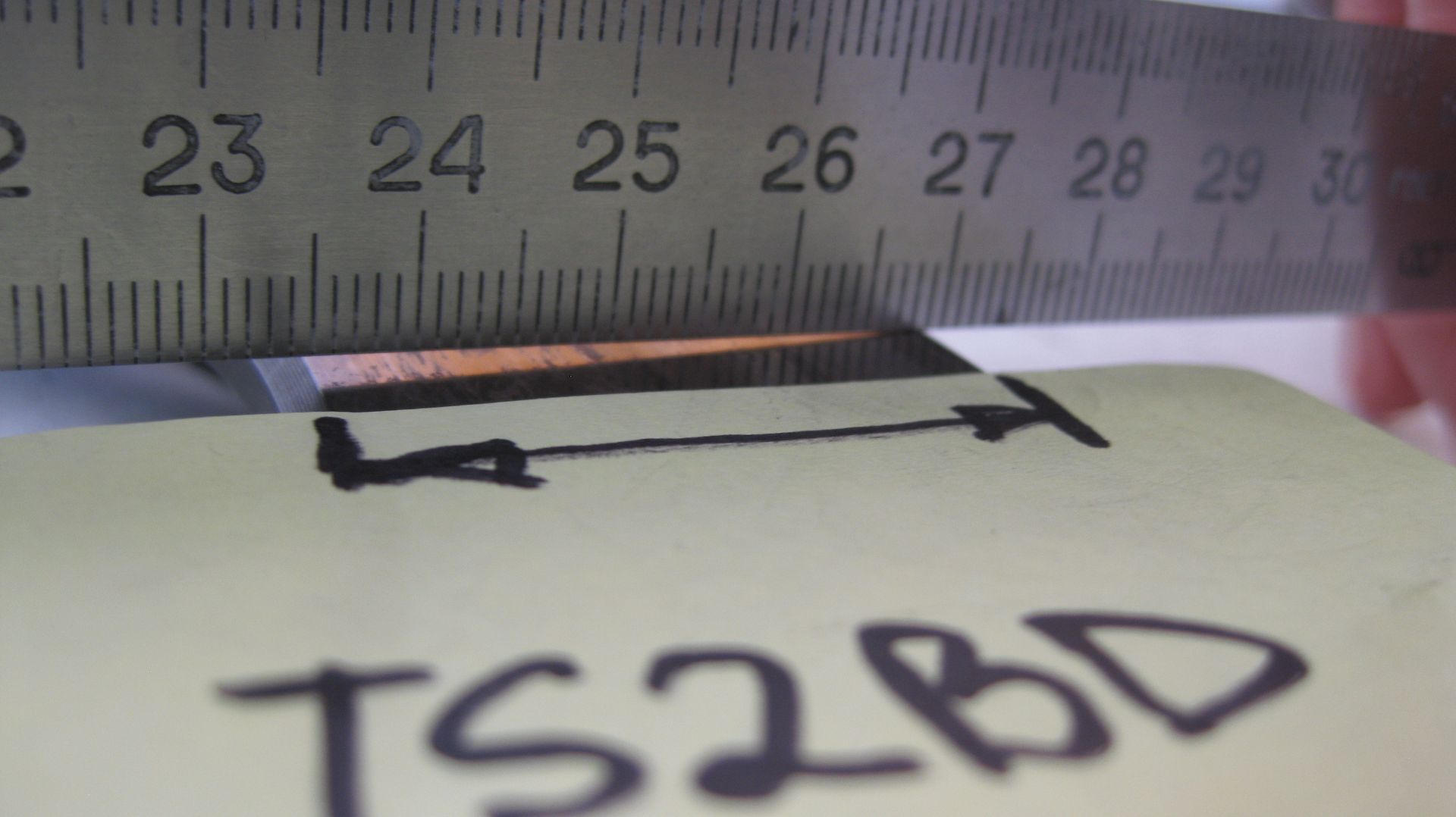

#2 TS3B

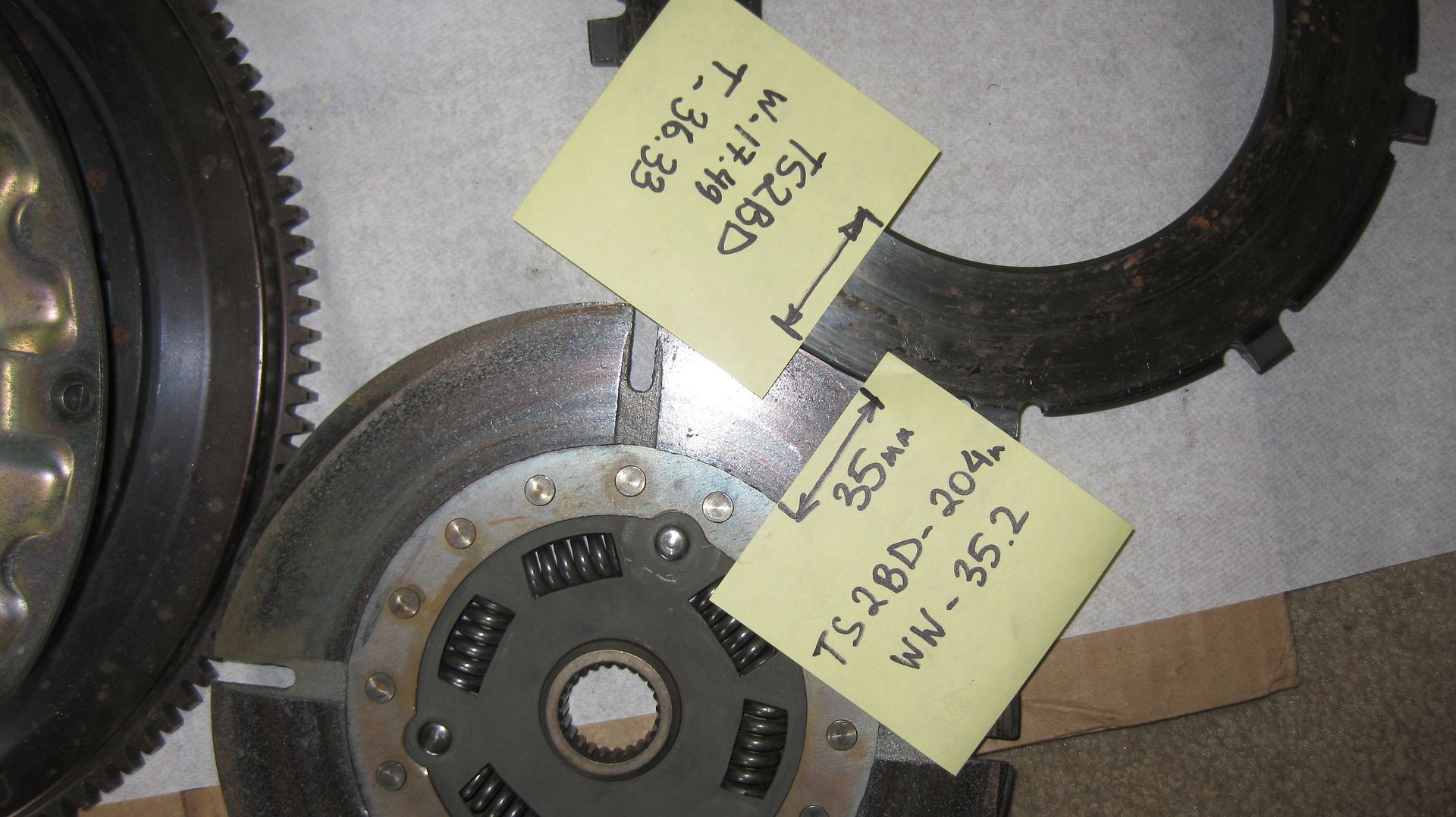

#3 TS2BD (Worn Out)

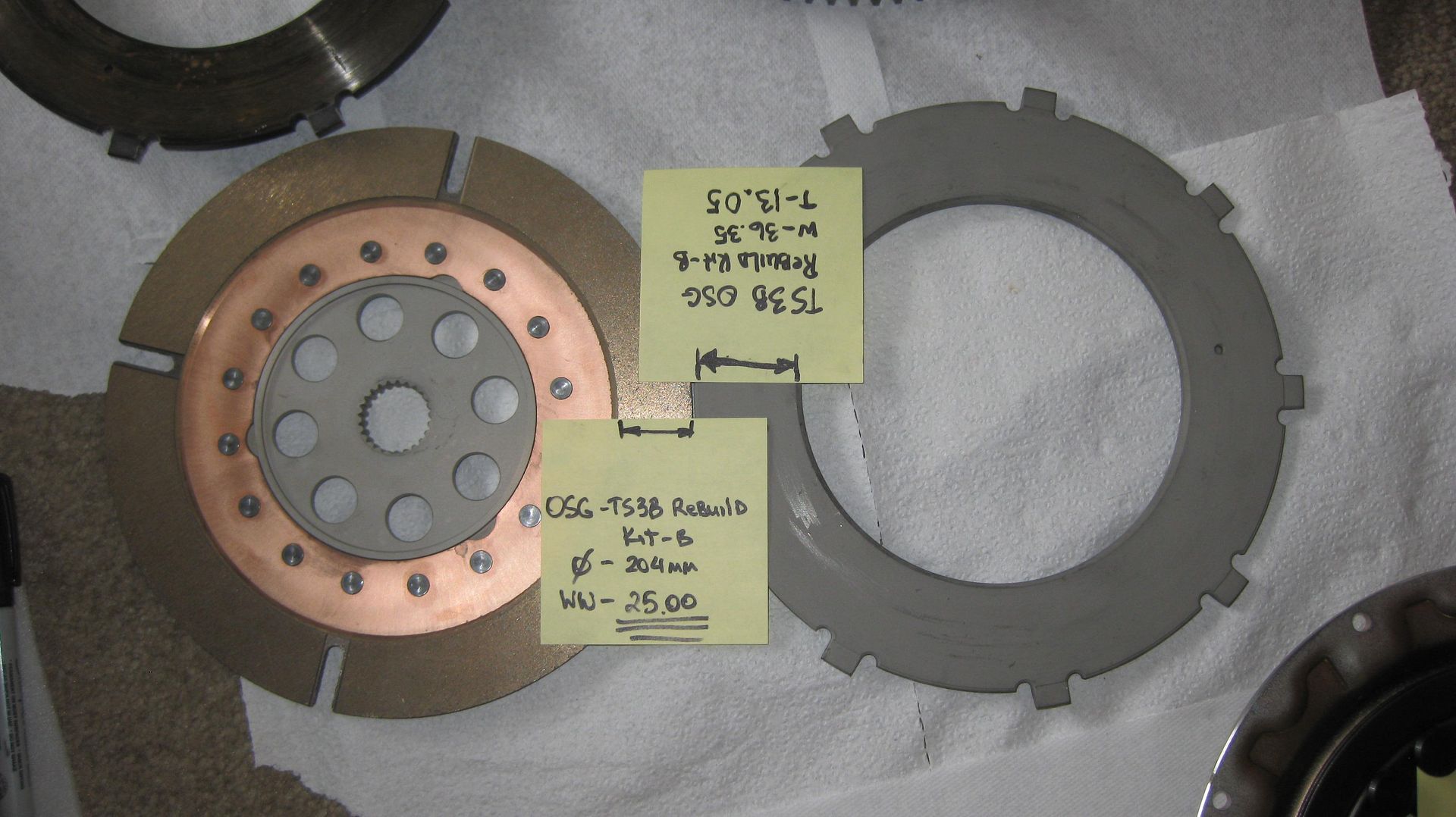

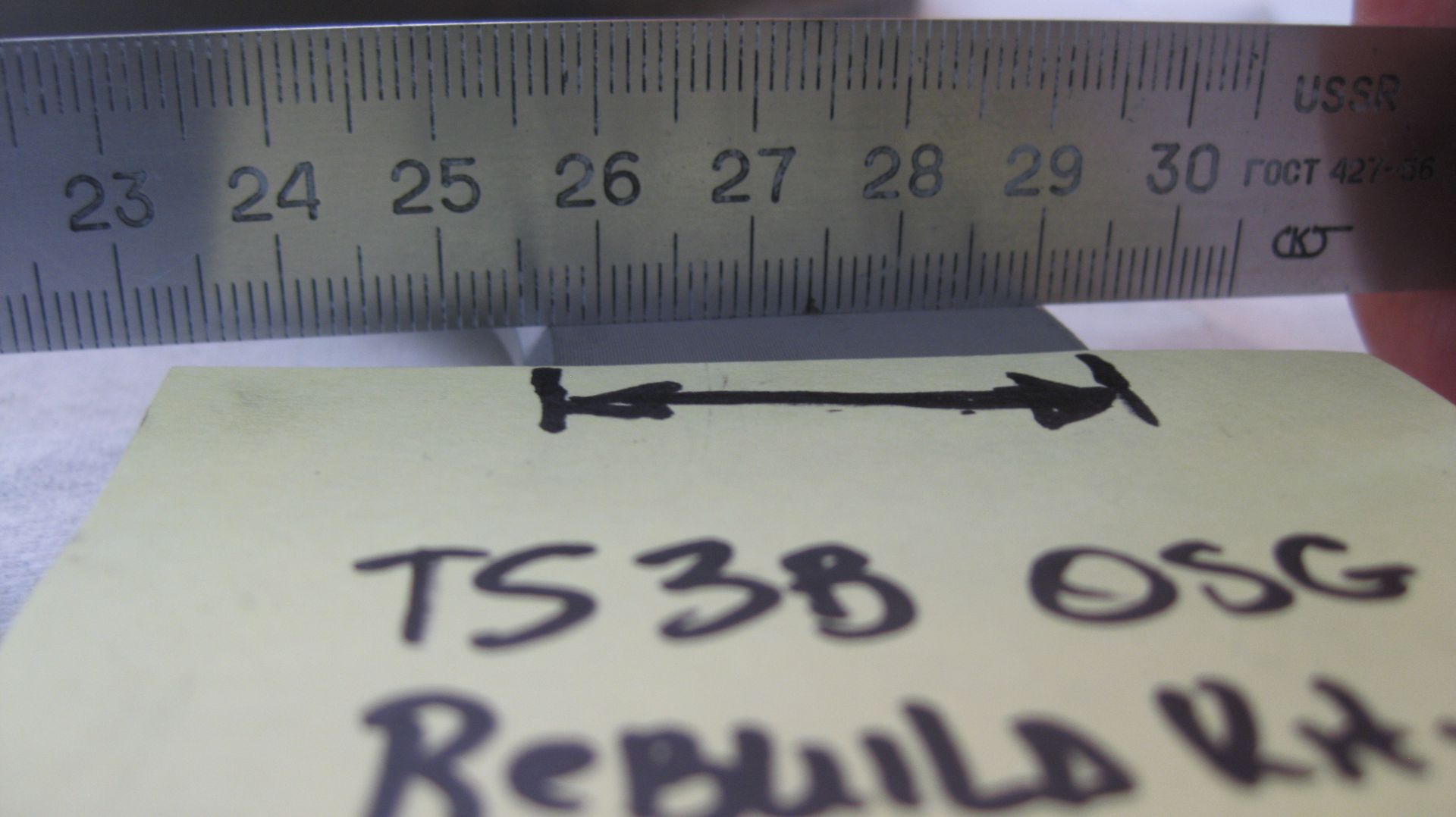

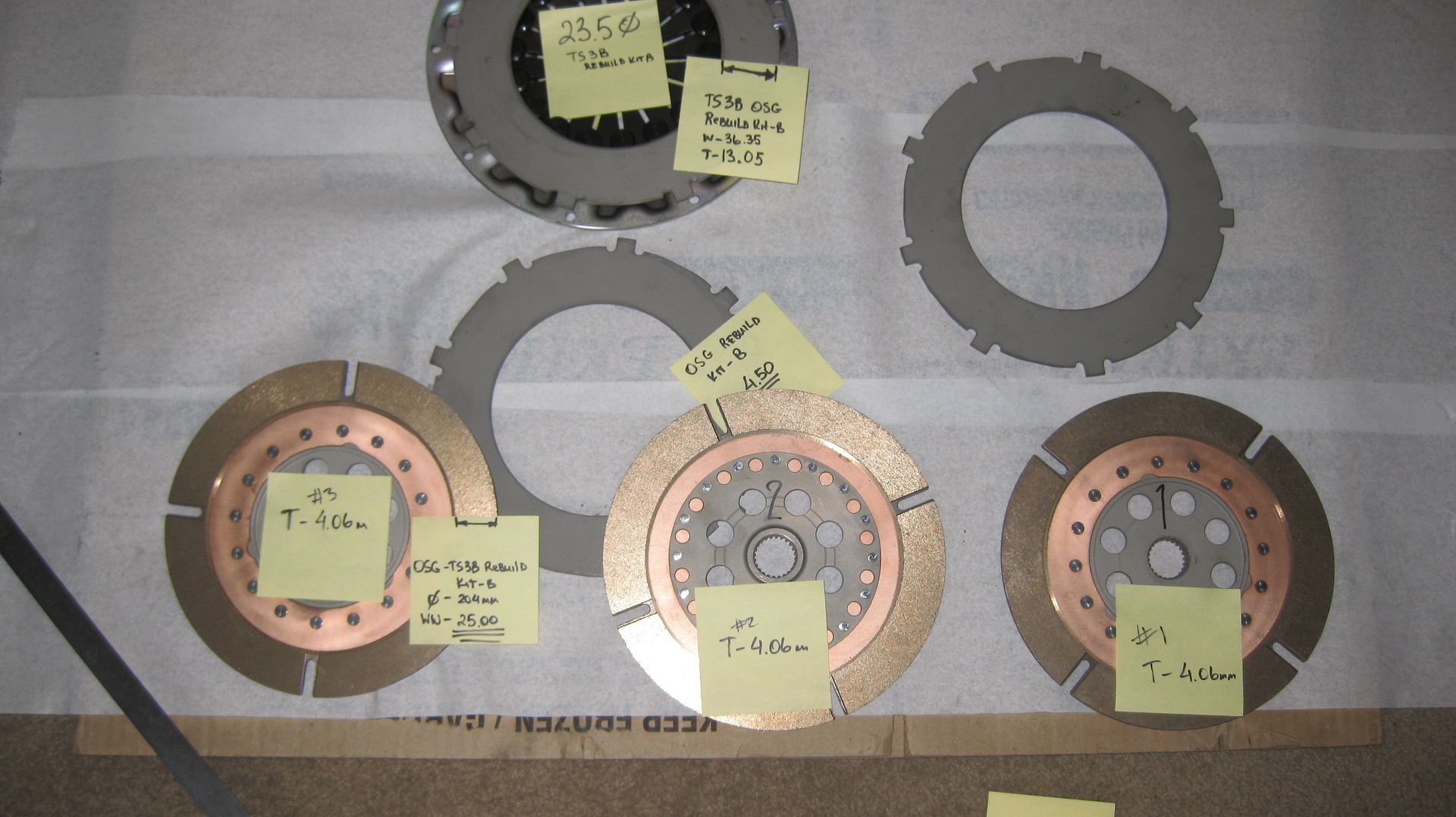

#4 TS3B Rebuild kit B (Brand new)

#5 TS2CD Rebuild kit (Most time is irrelevant)

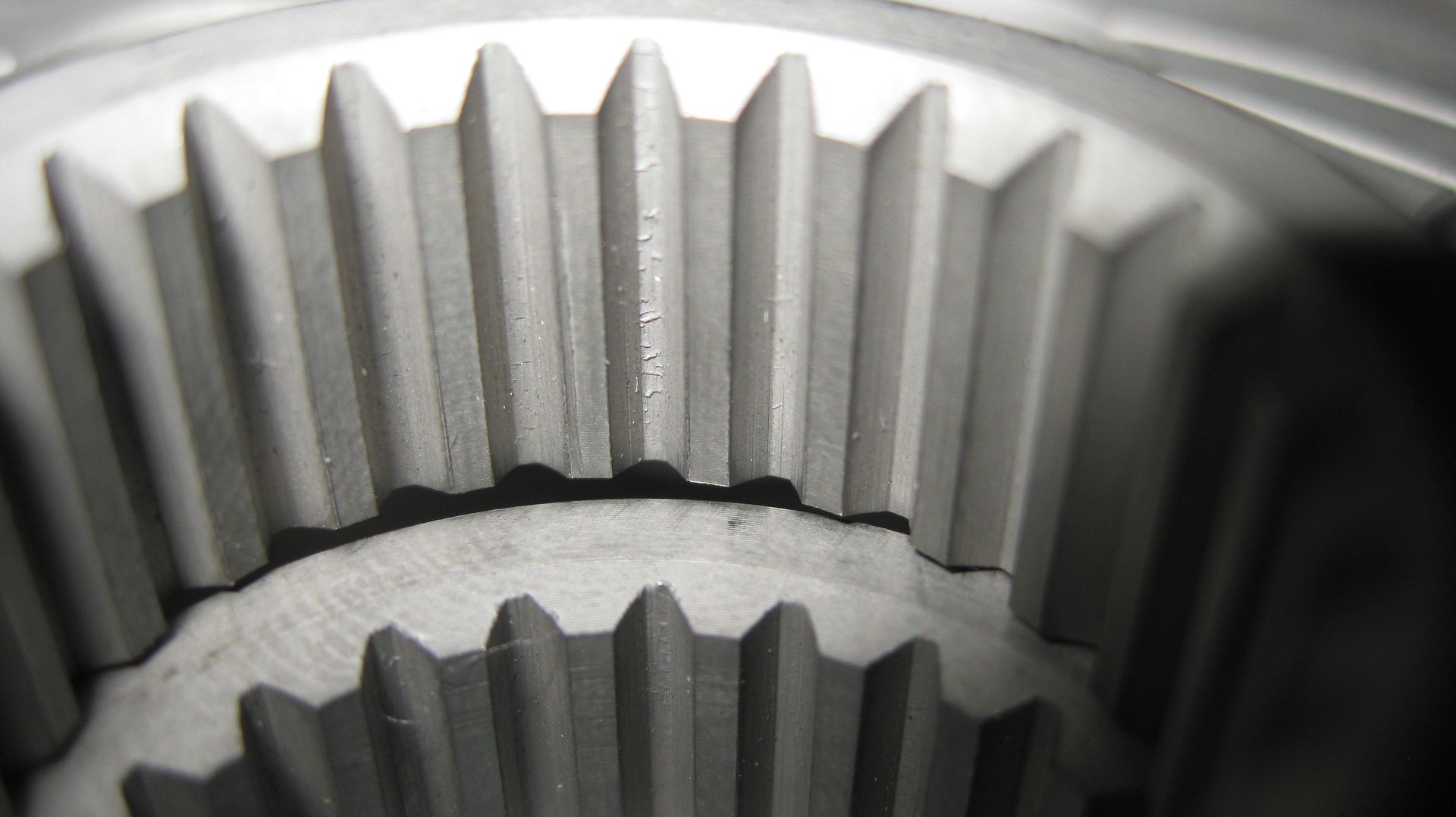

NOW, every clutch starts with Pressure Plate (OSGiken world - Clutch Cover), so here it is!

TS2BD has engraving letter B-D which I think indicates the thickness of the pressure plate depending on the application where TS2CD, TS3B and NEW REBUILD KIT TS3B clutch covers have engraving of BDP440

Pictured OLD TS3B and NEW REBUILD KIT TS3B

Well, here is my disappointment with OSGiken #1

OLD TS2CD and TS3B are 3.85mm where the NEW REBUILD KIT TS3B is only 3.60mm, I know it seems very small of a difference but isn’t it always about the little things? Measurements were taken in multiple places at the very outer diameter on holes and between them around the clutch cover! Basically OS reduced the thickness of new clutch cover here!

Just a note here: My current TS2BD that I modify and is still in my car was modified from being a 9 bolt cover to a 18 bolt cover because pressure plate was “LIFTING” from the center plate when bolted by 9 bolts, I know it is not a regular person task of modifying OSGiken clutch but I did it and it worked great!

Now, pressure plate, note, WORKING WIDTH is not precise as the surface that work with clutch disc is rounded off to a complete width so this measurement can vary and only here for reference! The thickness of pressure plate is also different (if you ever seen the OS clutch then you can understand of what I mean) depending on application. YES you can fit TS3B pressure plate into TS2BD but it WILL NOT work! Since when you tight down the bolts clutches won’t be tightened against the intermediate and the system just won’t work!

#1 TS2CD - W33.32; T17.50

#2 TS3B - W36.32; T12.99

#3 TS2BD - W36.36; T17.49

#4 TS3B Rebuild kit B - W36.35; T13.05

#5 TS2CD Rebuild kit - W33.32; T17.50

NEW vs OLD - No complaints here, everything looks like it really should!)

Next is going intermediate plates.

ALL OSGiken intermediate plate was roughly 4.43 – 4.45 where the ones from NEW TS3B Rebuild kit B were SOLID 4.50, this makes me say here that thickness of the new plates should be 4.50 so you can figure out how worn is yours based on this! Once again, NO complaints for NEW vs OLD!

Next is the most disappointing part – clutch disc! WW – my way of calling “Working Width” of clutch disc.

#1 TS2CD – WW 32.5

#2 TS3B – WW 35.00

#3 TS2BD - WW 35.00

#4 TS3B Rebuild kit B – WW 25.00 WTF??????

Yes, some people can say that maybe OS played with ceramic ingredients of new rebuild kit, but I highly doubt this. Their clutches was bulletproof so I think they decided to reduce at least the life of them this way!

As we can see width of the clutch disc is combined with intermediate plate width:

#5 TS2CD – Disc 32.3; Plate 33.32

#1 TS2CD – Dics 32.5; Plate 33.32

#2 TS3B – Dics 35.0; Plate 36.32

#3 TS2BD – Dics 35.3; Plate 36.33

#4 TS3B – Dics 25.0; Plate 36.35! This lower width will mean that there be more pressure (per square inch) from pressure plate spring to a total surface area and this will definitely cause step effect on the plate, im not sure if it is a bad thing or not yet, but I DO NOT like this!

Project at this point!)

Another interesting point here, I never owned a brand new OSGiken clutch but I’ve noticed that all pressure plates were CONCAVED to the center, which in my opinion is making at least first disc wear uneven! My camera is pretty old so I am sorry for some unclear pictures.

TS2CD

TS3B

TS2BD (You can see that WW is not the complete Width of the plates as stated earlier)

But #4 TS3B Rebuild kit B showed me that brand new PPlates came very straight and this means that it is a physics fault where smaller diameter metal wears out faster than the outer diameter!

As a very last point I want to say this once and for all, brand new clutch thickness of OSGiken discs is 4.06mm!!! Even though that this measurement is from this particular TS3B Rebuild kit B, I am pretty sure it is the same for all OSGiken clutches!

Summary.

The point of this thread is to educate people and show them internals of different OS clutches especially that at one point of time I had all this clutches available to me! I did contact OSGiken and the reseller who sold me this clutch rebuild kit and, NO, there is NO mistake/s in my order, all parts ARE for TS3B.

You should look at the difference of NEW vs OLD design because this reduction in width is happening in all line up of OSGiken clutches including my favourite "R" series with independent center hub!

As im still very upset with downgrading quality and redesign of OS, I am going away from them until they do another update of their clutches, and I REALLY - REALLY hope it is going to be to the proper way! Furthermore in my research of my next clutch ive noticed that some other Japanese clutch manufacturer for example ORC using very very similar if not exactly same discs as OS, if this discs using by others and are really identical why do they cost SO f... much?(

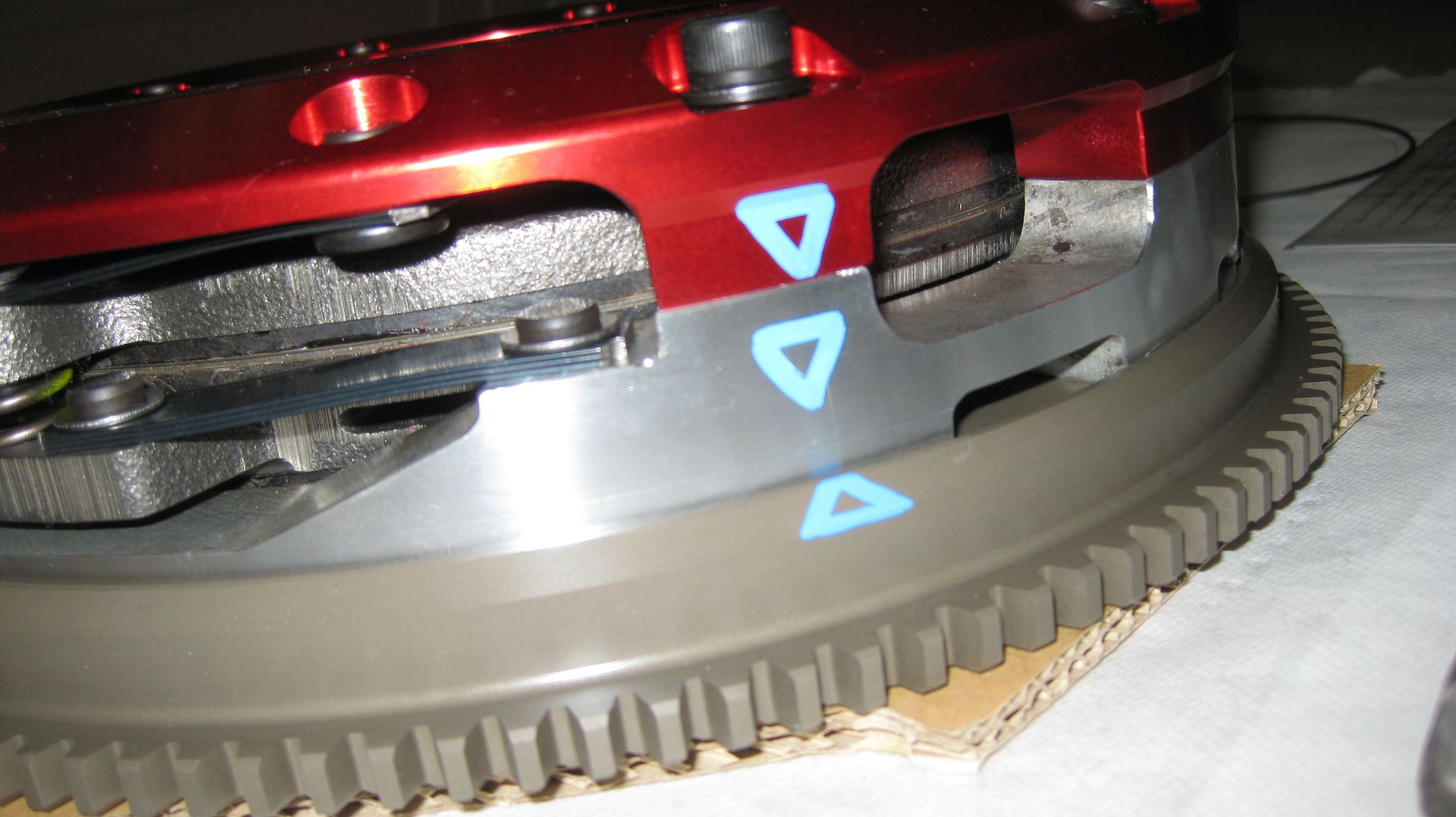

My next clutch that I’m going to throw onto my GTR will be Nismo SUPER COPPERMIX TWIN Competition which should coupe with my current power pretty good. I am also looking at ATS Triple carbon but can’t really find recent reviews of it, all of them are 3-5 years old and older, way back when Carbonetics was still around! I will update this thread as I will move on to the new clutch brand! And maybe if there is enough interest do a thread of how I modify my current TS2BD.

Just like before, do not post few words just to get automatically subscribed to this thread, there is a “Thread Tool” just above the first post where you can easily do that! I mean you can post your opinion, like and point of view about this and i really hope one day OS rep will see this!

PS: I Need a better pictures hosting website, my photobucket is reducing their size and seems that i cant post full size pics anymore!(

Comment