moar pics, moar powerrrrr!!! rawrrrrr!!!

Announcement

Collapse

No announcement yet.

ARC240's RB20DET 240SX Build

Collapse

X

-

Listen up, you little italian bastard! I want more pictures!!!!!!!!!!!!!! send through PM, and keep all these other koons wondering ..... DO IT you stallion..

..... DO IT you stallion..

bscmotorsports.ca

bscmotorsports.ca

Arctic Cat Fircat F7 Sno pro

"You mean, let me understand this cause, ya know maybe it's me, I'm a little f*cked up maybe, but I'm funny how, I mean funny like I'm a clown, I amuse you? I make you laugh, I'm here to fuckin' amuse you? What do you mean funny, funny how? How am I funny? Whaat the f*ck is so funny bout' me, tell me, tell me whats funny..."

Comment

-

Indeed, let me get back to you with pricing on that, turn-around time for me getting them is usually 12-24 hours. Been soooo busy dude, shoot me a PM plzOriginally posted by m_melen View Postps-any news on a timing gear and that little backing plate for it? .

.

NOW...MOAR PICS!!!

The head was finally reassembled, all the bolts were torqued to spec, brand new Nissan gaskets on both intake and exhaust side, although I really have a feeling that I should have gone metalic gasket on the exhaust side, price of OEM Nissan is rediculous .

.

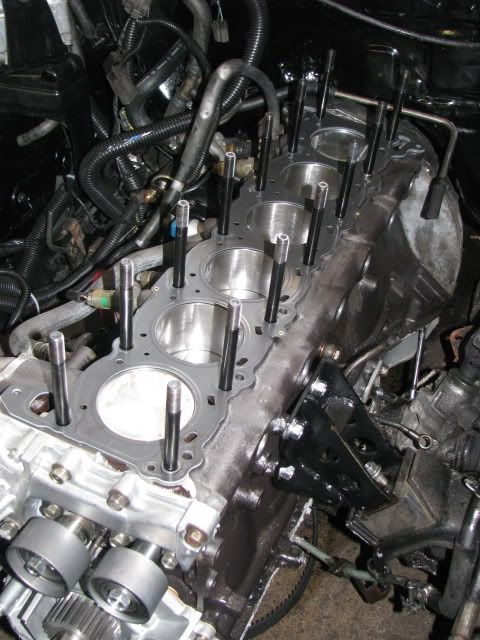

Cylinders all received a very light coating of oil to protect them from any moisture/etc that might build up before the engine runs. Cylinder 1 at TDC, THIS IS IMPERATIVE TO DO BEFORE THE HEAD AND CAMS GO ON!! I accidentally shifted 2 exhaust valves because I completely forgot to put #1 @ TDC, had to replace those valves, thus the reason for me taking so long.

ARP head studs + Tomei 1.2mm multi-layer metal head gasket.

Better shot of the buttoned-up bottom-end, ARP grease on both ends of the head studs and hand-tightened in as per ARP's instructions.

Put a new, still folded garbage bag over the studs to make a tent over the cylinders so no dust/dirt would get inside the cylinders while I was preparing the head. Can't be too careful .

.

Head up in the air after a good cleaning on the table ...some sturdy nylon rope works EXCELLENT for this job, it's thick enough to hold the weight and at the same time, wont scratch painted manifolds.

...some sturdy nylon rope works EXCELLENT for this job, it's thick enough to hold the weight and at the same time, wont scratch painted manifolds.

Underside needs some cleaning as well.

-

-

*sparkle, sparkle* LOL. Cleaned up the underside of the head with a clean microfiber cloth (doesn't release any lint, so perfect for creating the ideal sealing surface, cloth was soaked in brake cleaner (removes grease and stubborn crap very quickly), then I hit the underside with some low-pressure compressed air to dry it and get rid of any dust/sand that may have gotten under there while the head was off of the engine.

The head is introduced to the bottom end again, huge sigh of relief that everything went as planned. At least the RB20 is in 1 piece and looks like an engine now .

.

In the garage for all of today as well, so I will for sure post more pics by tonight, just torqued the head down in a 3-stage process as-per ARP's instruction, I like to wait about an hour after and then re-torquing the studs to final torque one last time before cams go back in.1992 NISSAN 240SX - RB20DET POWER

1990 NISSAN 300ZX - 2+2

Comment

-

can u post up torque specs

Comment

-

-

GUYS! GUYS! GUYS!

HUGE UPDATE!!! Engine might be absolutely fine! Only reason for low compression is the fact that the rings haven't seated themselves yet or formed to the cylinder walls, so naturally, the engine wont produce 100% compression. A couple of my cylinders were producing VERY little compression, tossed a teaspoon and a half of oil in and up went the compression. Not only that, but I'm rotating the crank by hand...which wont net nearly the same results as using the starter.

I'll keep this updated as the day goes on.1992 NISSAN 240SX - RB20DET POWER

1990 NISSAN 300ZX - 2+2

Comment

-

i dunno dude, are you supposed to have low compression whenever you put in new rings? sounds kinda sketch to me.

oh, and throw up the head stud torque numberI've been brushing my teeth with jack but it's resulted in terrible amounts of tooth decay.

Comment

-

The rings arent going to be properly seated yet, so yes the numbers will be lower before a motor is broken in. Break in will allow the rings to get lapped with the cylinder walls creating a better seal.Originally posted by m_melen View Posti dunno dude, are you supposed to have low compression whenever you put in new rings? sounds kinda sketch to me.

oh, and throw up the head stud torque number

Comment

Comment