It is indeed a work of art. You must be very proud of yourself! Gratz on your achievement.

Announcement

Collapse

No announcement yet.

Midnight Purple R33 GTR EFR8374 Build

Collapse

X

-

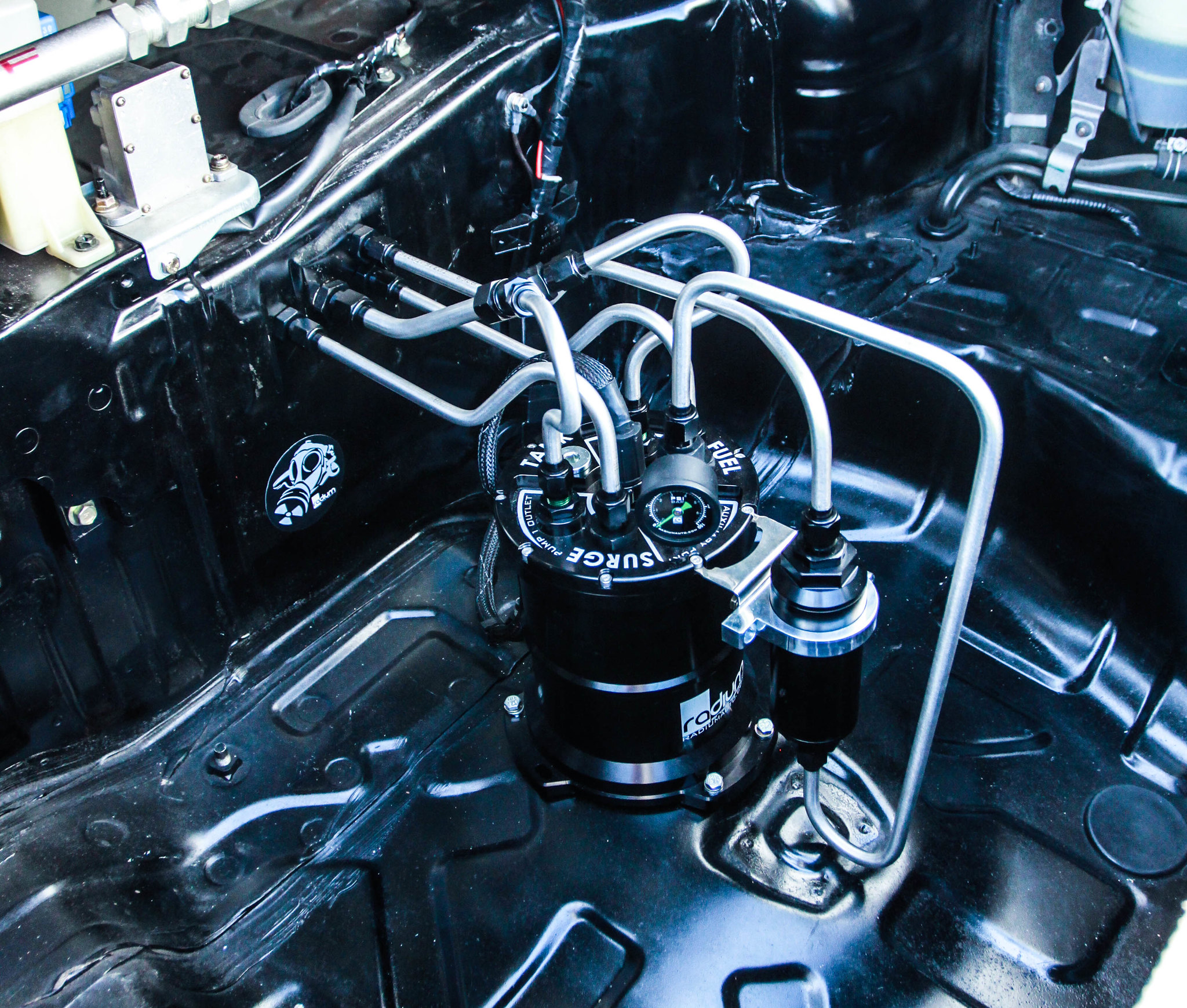

-6an (3/8") braided line from the fitting at the tank to the bulkhead fitting through to the trunk. -6an tube nuts and sleeves for the stainless steel 3/8" lines (0.030" wall thickness, thinnest I could find) in the trunk to tge surge tank. The fitting on the tank is actually 5/16" from what I remember but -5an fitting don't really exist and the line is low pressure between the stock tank and surge tank and I've had no leaks with the 3/8 lines clamped tight onto the 5/16 fitting.Originally posted by Black BNR32 View PostNice fuel set up. what line and fittings did you use to feed the surge from the stock tank?

Comment

-

Under the car I removed the oem evap and fuel lines. I disassembled the brackets that hold the stock lines and reused them with rubber insulated clamps to hold the new stainless lines:

Made a bracket and used bulkhead fittings to support the back:

Used the old brackets I reused in the middle. Bent all the lines to be as close to the body as possible:

Last edited by sb119; 04-13-2015, 05:35 PM.

Last edited by sb119; 04-13-2015, 05:35 PM.

Comment

-

Would yu mind sharing details on the hard lines? Like:

Was there any joints or 1 piece?

What was the cost give or take?

Flared/inverted flare fittings or swagelock stuff?

I've been meaning to do solid lines for a while and even kept the hicas lines to use for fuel...No build thread.

1991 nissan

El terror

"Built not bought" sooner or later = "broken not running"

Comment

-

Thanks for the comments.

Some details on the fuel system:

Starting at the bulkhead fitting at the back (3rd pic in last post) the feed line is one piece to a bulkhead fitting in the engine bay, then a U shaped bent line to a 10 micron filter. From the filter I used flexline to the fuel rail so the line is able to move a bit with engine movement/vibrations. The return lines is one piece to the engine bay and flexline to the fuel pressure regulator which I have mounted on top of the intake manifold.

Steel lines themselves were cheap, about a dollar a foot. The tube nuts and sleeves for connections are cheap too. The expensive part was the tools for bending, flaring, cutting, deburring, measuring angles etc.

It's also ridiculously time consuming. I had to relearn trigonometry and had pages of calculations to get all the lines in the trunk to work. In hind-site I mounted the surge tank too close to the bulkhead and it made the bends fairly tight and complicated.

Lines are all 37 degree single flared and AN fittings.

Comment

-

This is also where the boys are separated from the men lol. You did a killer job; stuff is more than time consuming it's a legit art getting it right.Originally posted by sb119 View PostThe expensive part was the tools for bending, flaring, cutting, deburring, measuring angles etc.Originally posted by archaeic_blokehows the warp drive? i've seen far too many GTR's lately that just arent able to hit warp speed.

Comment

-

Took the car to Epic Metal Services in Medicine Hat to get some parts fabricated. They made me a downpipe, inlet pipe, intercooler piping, added onto my roll cage and welded some other various parts for me.

I used Dei titanium heatwrap on the downpipe

Turbo also got a DEI turbo blanket and the firewall got treated to DEI reflect-a-gold

Made custom oil and coolant lines for the turbo

Installed OS Giken R3C clutch and release bearing

Lots of new parts. Carbon fiber hood to clear the turbo. Aerocatch hood pins. Series 3 R33 GTR projector headlights. Recaro driver seat. R34 GTR passenger seat. Black Takata harnesses.

Comment

Comment