Hello, I would like to share this information to all GTRC community! Recently i ordered some parts for the main RB26 problem - oil pump!

I bought a couple of used oil pumps, order a crank collar (from Australia dealer) and a Reimax gearset directly from Japan!

Here is my findings:

#1

Outside diameter of the N1 pump is ~77mm, the STD is ~81mm, they do looks like they made from very different materials! I do not have any dots on the used STD pump gears (like on the N1) that i bought from the guy on this forum! I would dream to have the gears already replaced with performance, but im still pretty shure they are stock!

N1 Has 11 tooth and the STD has 12!

#2

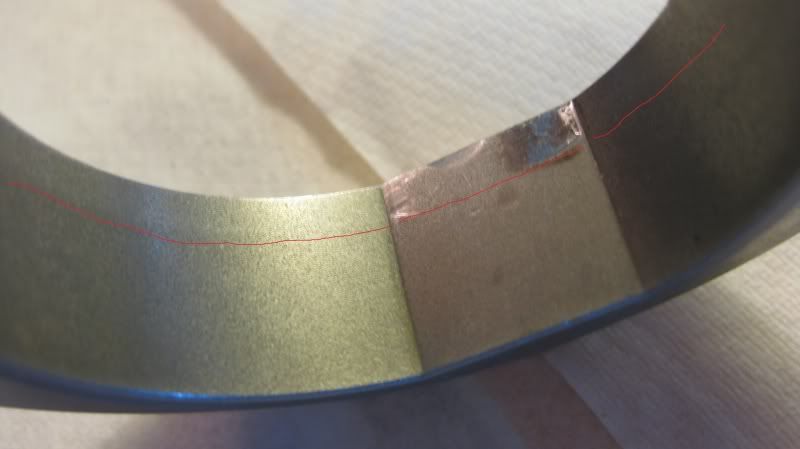

The collar from Australia, the guy is telling me that he copy the actual JUN collar and i do believe him. It looks like a very quality product, BUT it is very wobbly in the standard oil pump and even more wobbly in the REIMAX oil pump gearset. Here is some pics:

Side clearance on the standard pump is .013 one side and .010 on the other so ~.011 - .012, comes to a ~.006 each side. I think this is crazy large!

So if i measure clearance the same way on the Reimax gearset, this numbers are growin even higher! .018 and .016, so comes to a ~.008 each side. OMG.

Reimax gearset is ~81mm outside diameter but it similar to a profile of an N1 pump. I guess they make that to lower the cost of the product, the inside gear stays the same and the outside (internal gear) is slightly larger(STD) or smaller (N1) depending on the application! But Reimax gear looks very very nice!

#3

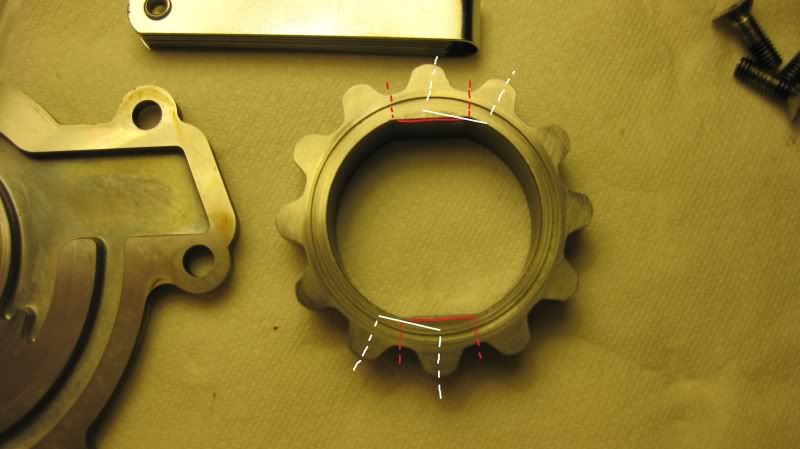

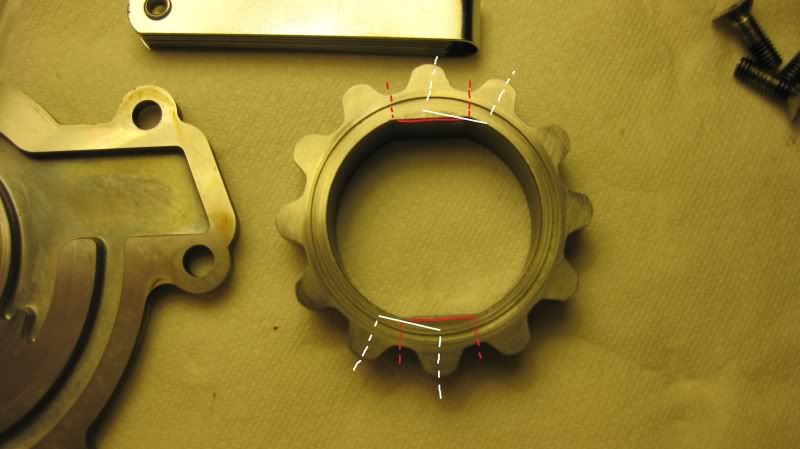

And in the end i just would like to say what if Nissan production would rotate the oil pump gear half tooth ether way, than the common breaking point would be MUCH MUCH stronger. But this is just my personal opinion, and it would probably worked only on STD pump gear with 12 teeth! (in RED - common breaking point)

The next thing is im going to try is JDMS13RHD collar as he is promising me that his collar would be within MY spec of clearance, at least for my STD pump!

Here is the link to the thread where i did some thread quoting and some information about N1 and Stock oil pumps

Here is the link from GTRUK, guy comparing Tomei, N1 and Reimax clearances on a brand NEW crank!

I bought a couple of used oil pumps, order a crank collar (from Australia dealer) and a Reimax gearset directly from Japan!

Here is my findings:

#1

Outside diameter of the N1 pump is ~77mm, the STD is ~81mm, they do looks like they made from very different materials! I do not have any dots on the used STD pump gears (like on the N1) that i bought from the guy on this forum! I would dream to have the gears already replaced with performance, but im still pretty shure they are stock!

N1 Has 11 tooth and the STD has 12!

#2

The collar from Australia, the guy is telling me that he copy the actual JUN collar and i do believe him. It looks like a very quality product, BUT it is very wobbly in the standard oil pump and even more wobbly in the REIMAX oil pump gearset. Here is some pics:

Side clearance on the standard pump is .013 one side and .010 on the other so ~.011 - .012, comes to a ~.006 each side. I think this is crazy large!

So if i measure clearance the same way on the Reimax gearset, this numbers are growin even higher! .018 and .016, so comes to a ~.008 each side. OMG.

Reimax gearset is ~81mm outside diameter but it similar to a profile of an N1 pump. I guess they make that to lower the cost of the product, the inside gear stays the same and the outside (internal gear) is slightly larger(STD) or smaller (N1) depending on the application! But Reimax gear looks very very nice!

#3

And in the end i just would like to say what if Nissan production would rotate the oil pump gear half tooth ether way, than the common breaking point would be MUCH MUCH stronger. But this is just my personal opinion, and it would probably worked only on STD pump gear with 12 teeth! (in RED - common breaking point)

The next thing is im going to try is JDMS13RHD collar as he is promising me that his collar would be within MY spec of clearance, at least for my STD pump!

Here is the link to the thread where i did some thread quoting and some information about N1 and Stock oil pumps

Here is the link from GTRUK, guy comparing Tomei, N1 and Reimax clearances on a brand NEW crank!

Comment