week4 - 2011, part 1/2

disclaimer :

the following story depicts actions that occured between May 22 and 26 2011

information is recalled purely from memory, endure with me

if you've read the last chapter, you have probably been wondering what the last picture was about?

well during the winter, i worked my arse off to find something i needed rather than wanted,

so i got this;

long story short, i couldn't find an affordable cage in Quebec, and didn't want to have it shipped since it would cost so much,

the reason i needed it was simple, to be allowed to use a racing harness during a time attack event, a roll bar was needed,

but the only things i saw for sale were full cages when i only wanted the rear half, and no one wanted to sell half of theirs,

so i got in contact with a shaddy caracter here in Quebec, who said he'd sell me his full cage cheap,

but then he tells me he sold it to someone else.. crap,

luckily that someone else knew what i was looking for and contacted me and offered to sell me only the rear portion of the cage he had just bought since he needed just the front bits,

and that person was GTRC's SKYGTR,

he even agreed to drive halfway (between Montreal and Quebec City) to meet, super cool guy,

what i got was 3 pieces of the rear section of a genuine Cusco roll cage, it was all wrapped with a protective foam,

i took it all off, and threw it in the garbage (i think)

so since at the time of the install, i was working full time at an internship, and i wanted so modding done to the cage, my dad jumped in again to help,

he brought the cage to a welding shop, literally around the corner from my house,

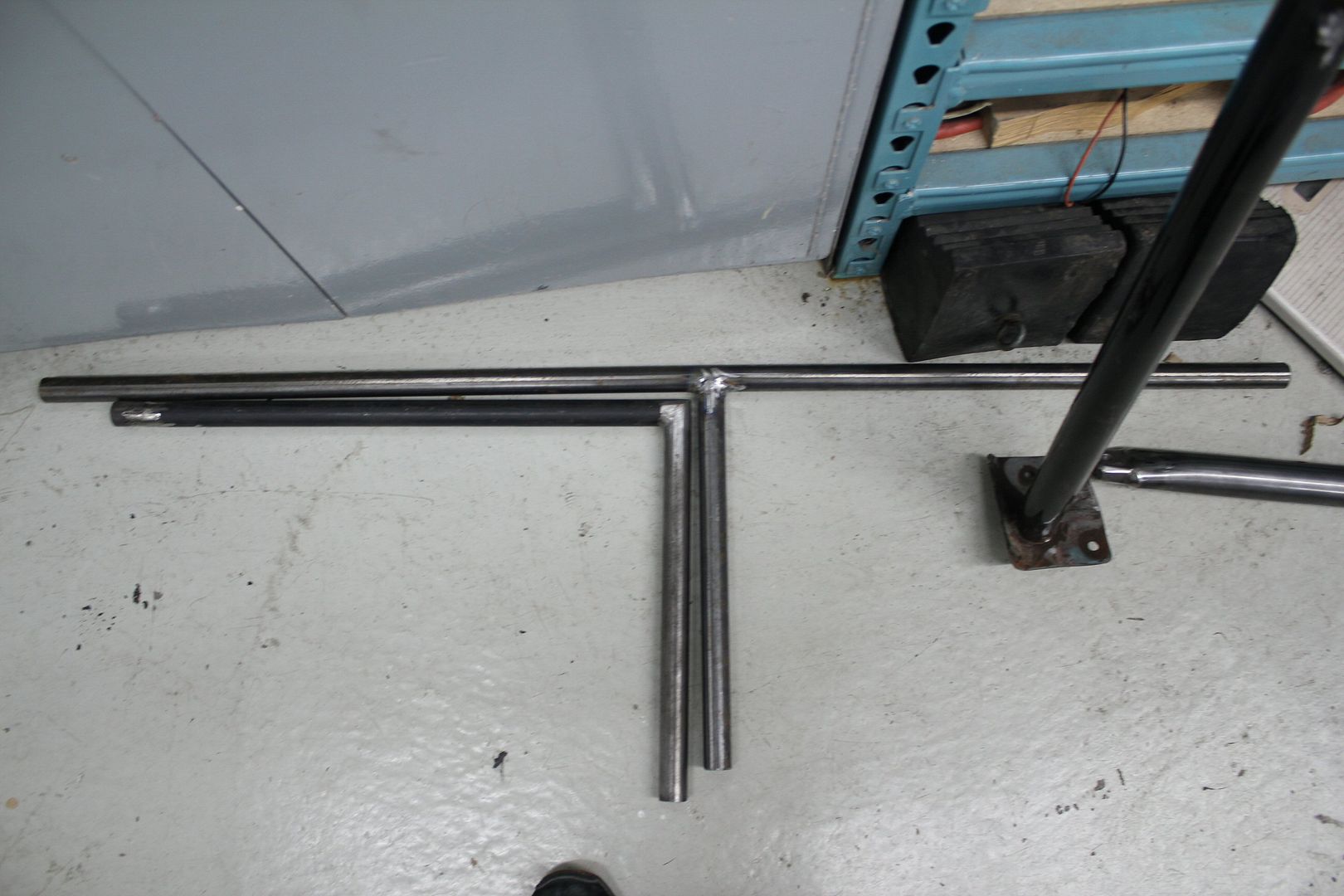

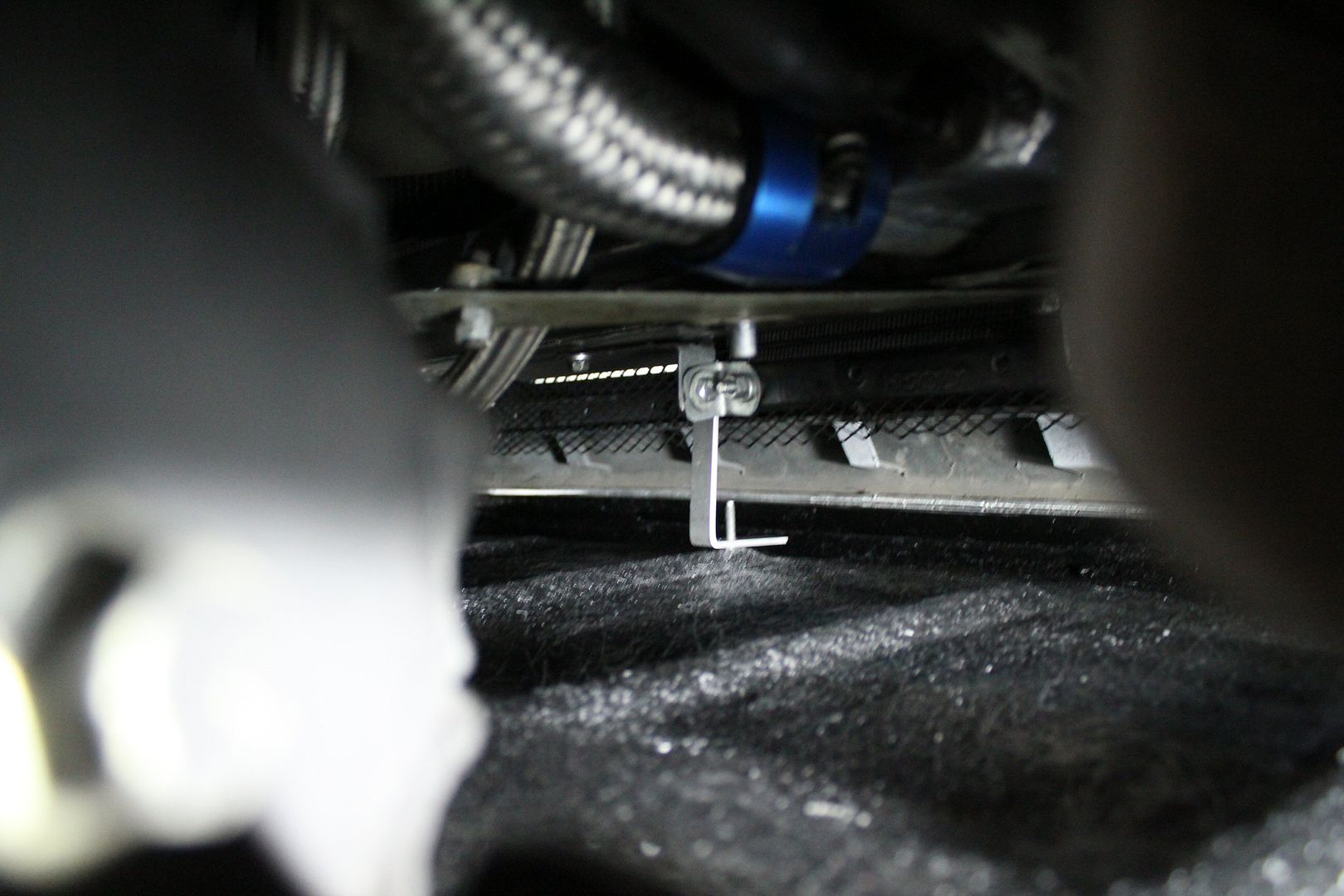

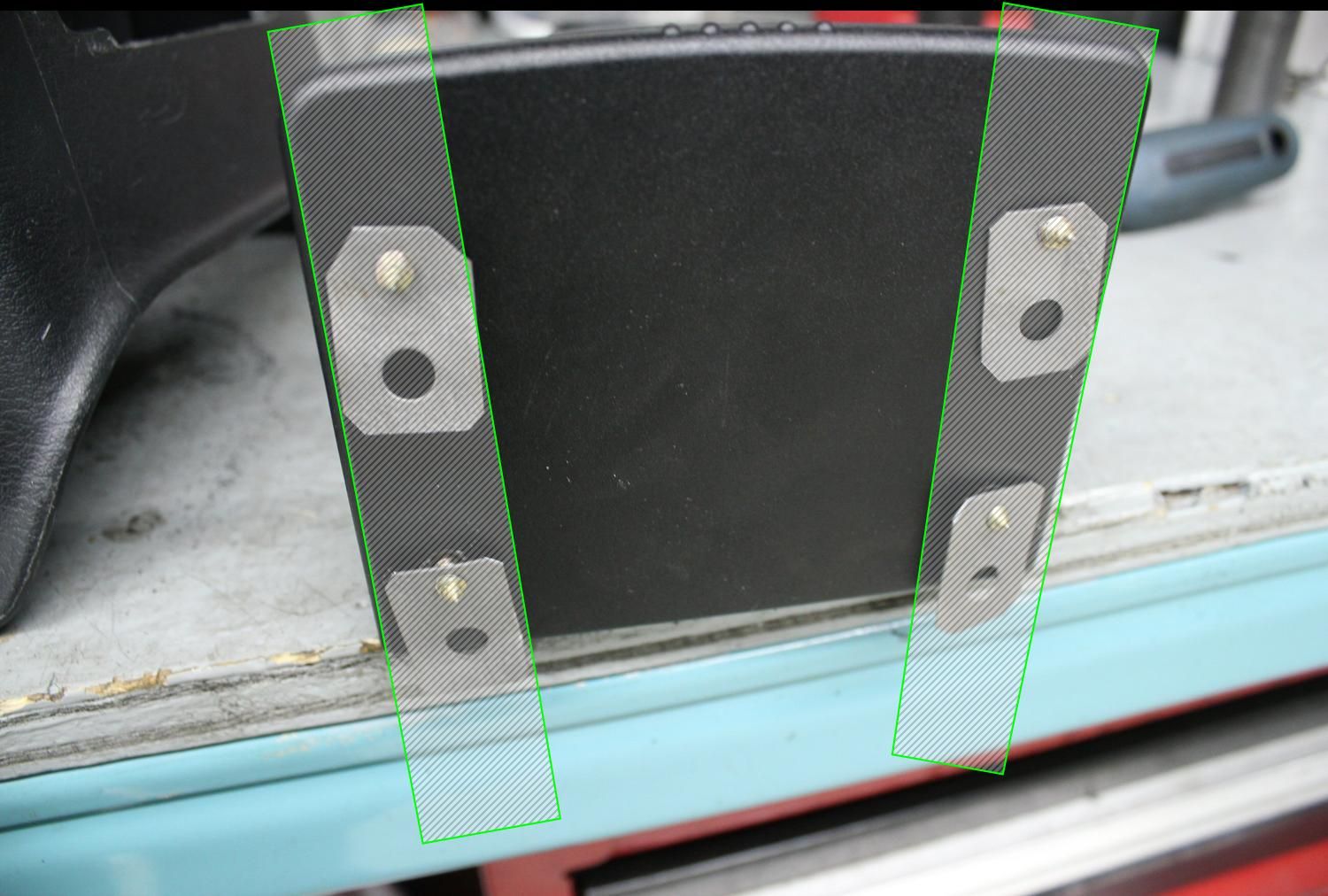

since i wanted to fit an harness bar to the cage itself, i had brackets welded to the cage at particular spot that i had measured;

i also had a simple L bar made to fit with the brackets

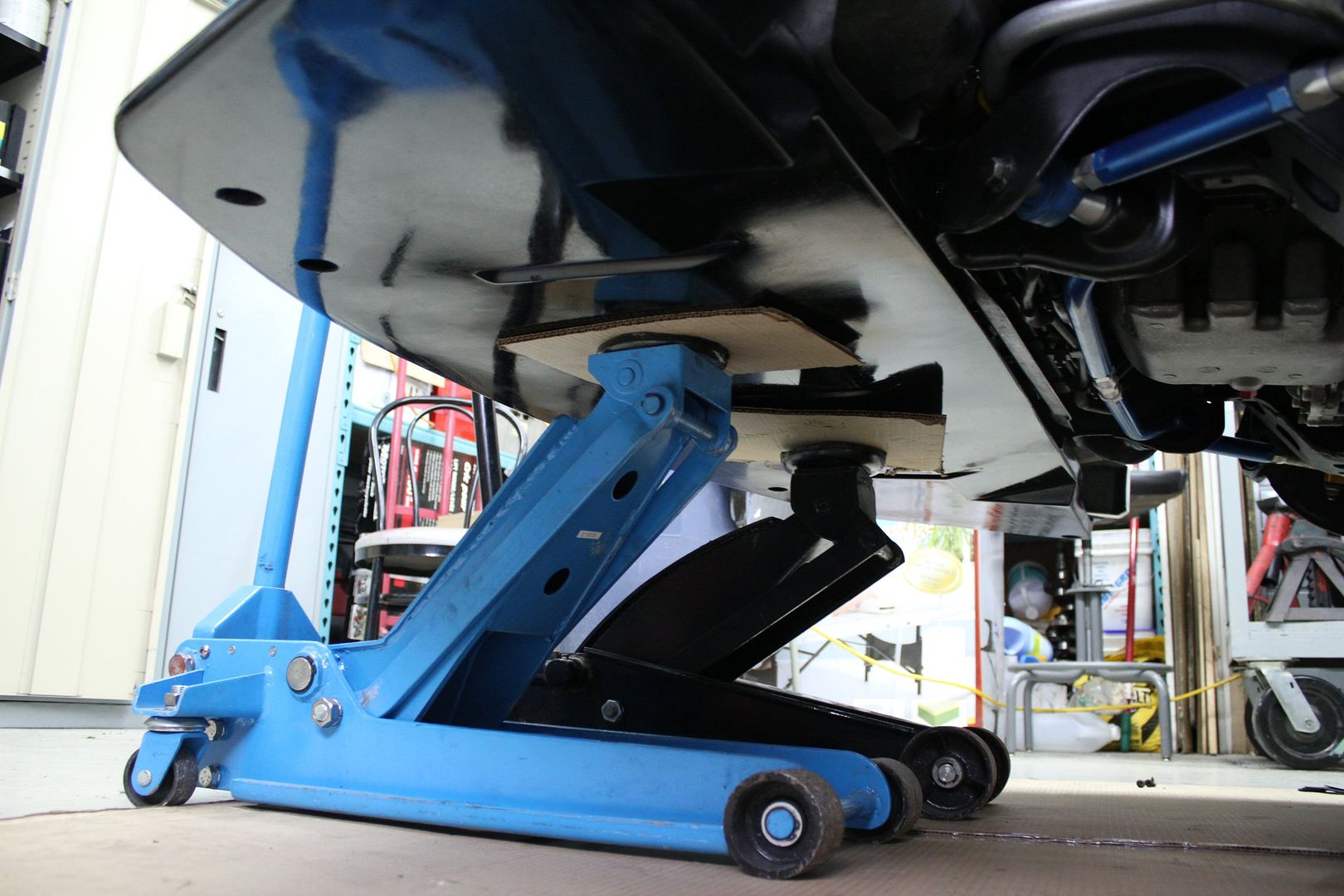

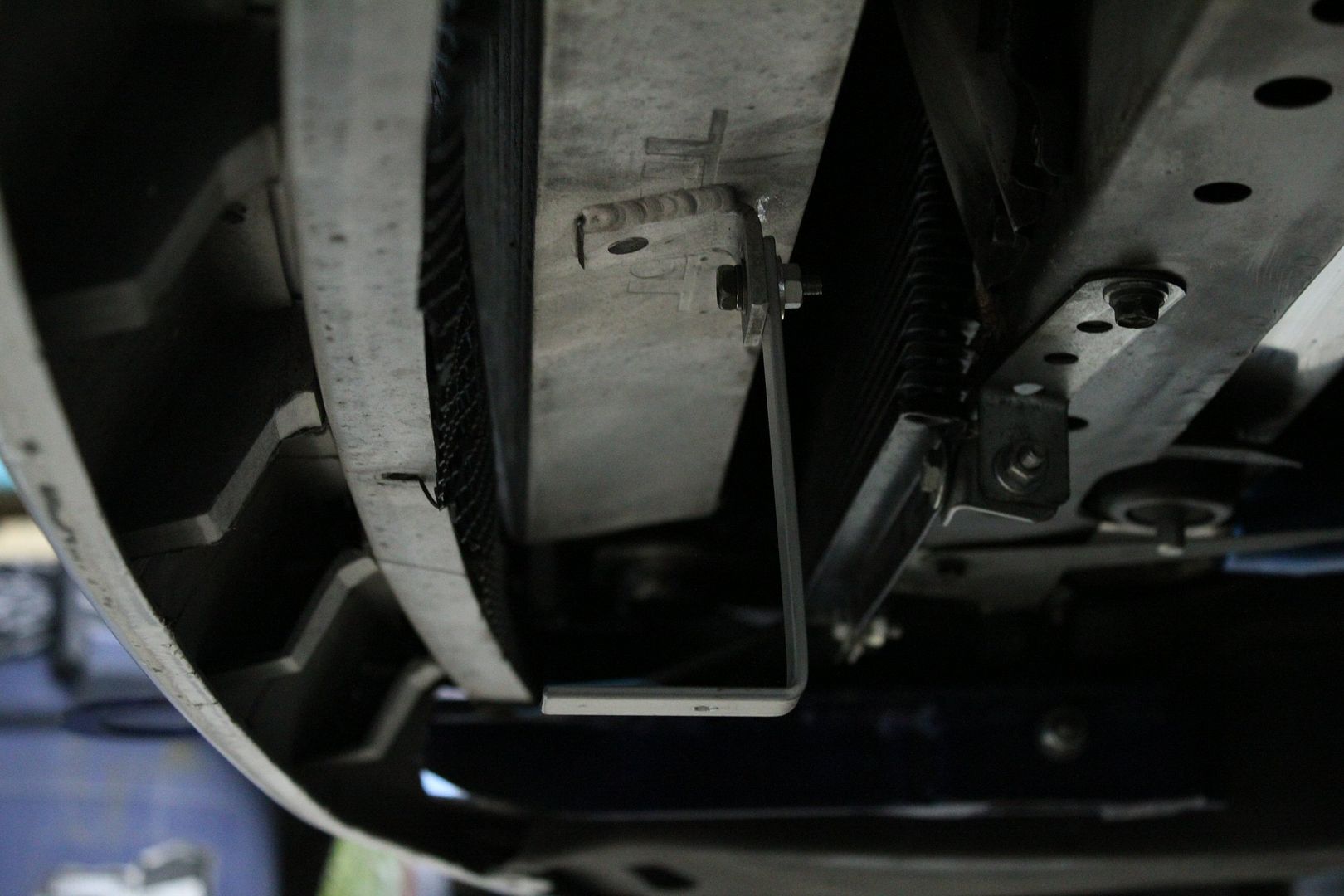

then, since i had previously removed everything from inside the car, i test fitted the cage's hoop,

and since i was keeping the carpet, the cage was a bit tight and i needed to wack it into place with a rubber hammer;

then put the L bar in its place to see if my approximate dimensions for the brackets was working out;

i even bolted the driver seat in and saw that the brackets didn't go far back enought,

the seat would hit the bar when slid all the way back, how i drive;

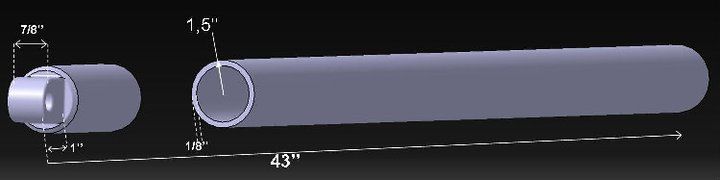

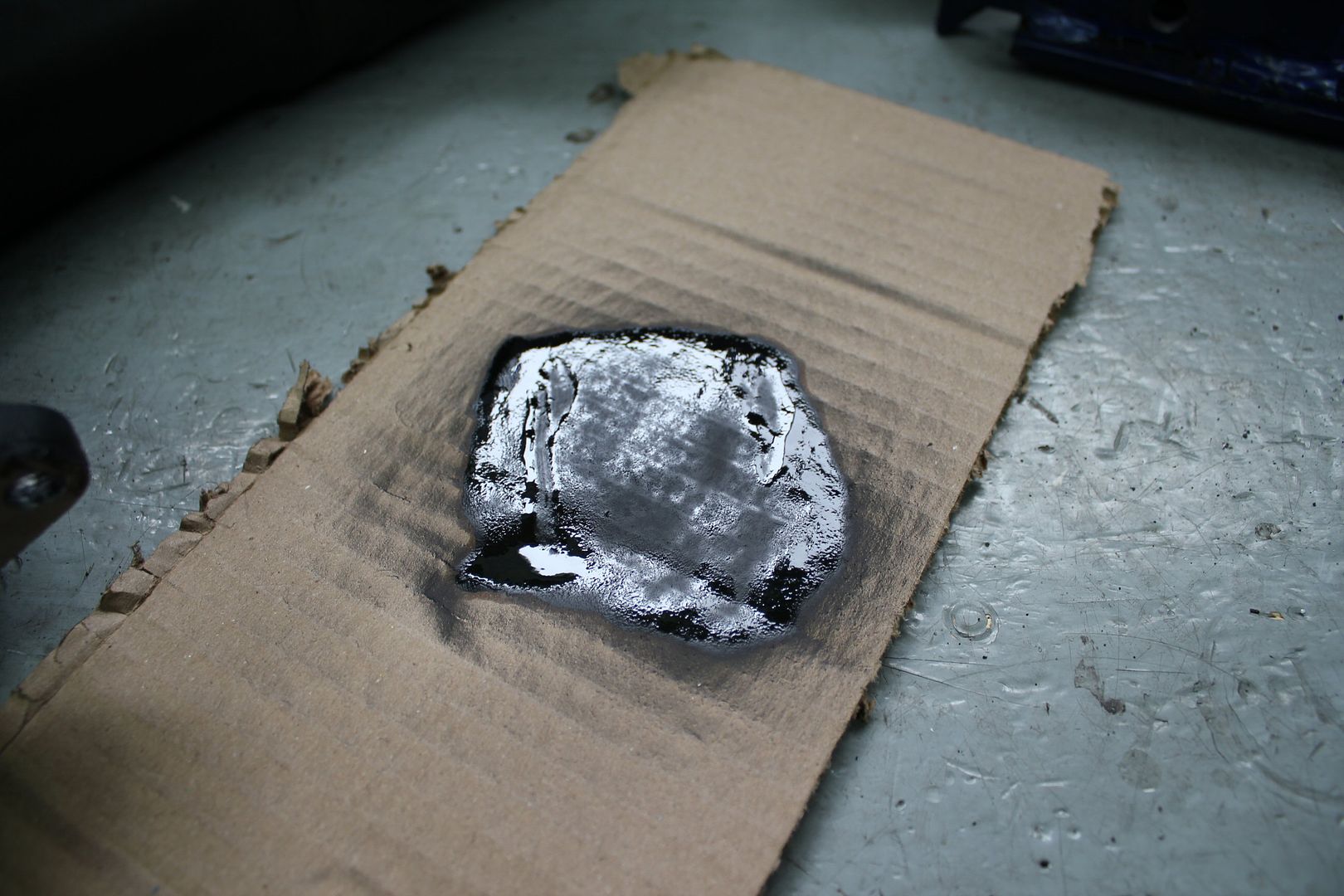

but before any of this was done, i had gone to another welding shop next to where i worked to get a cross brace made,

since i didn't have the Cusco original

the dimensions i gave the fabricator were based on measurements i took of a friend's Cusco cage during a meet earlier in the season;

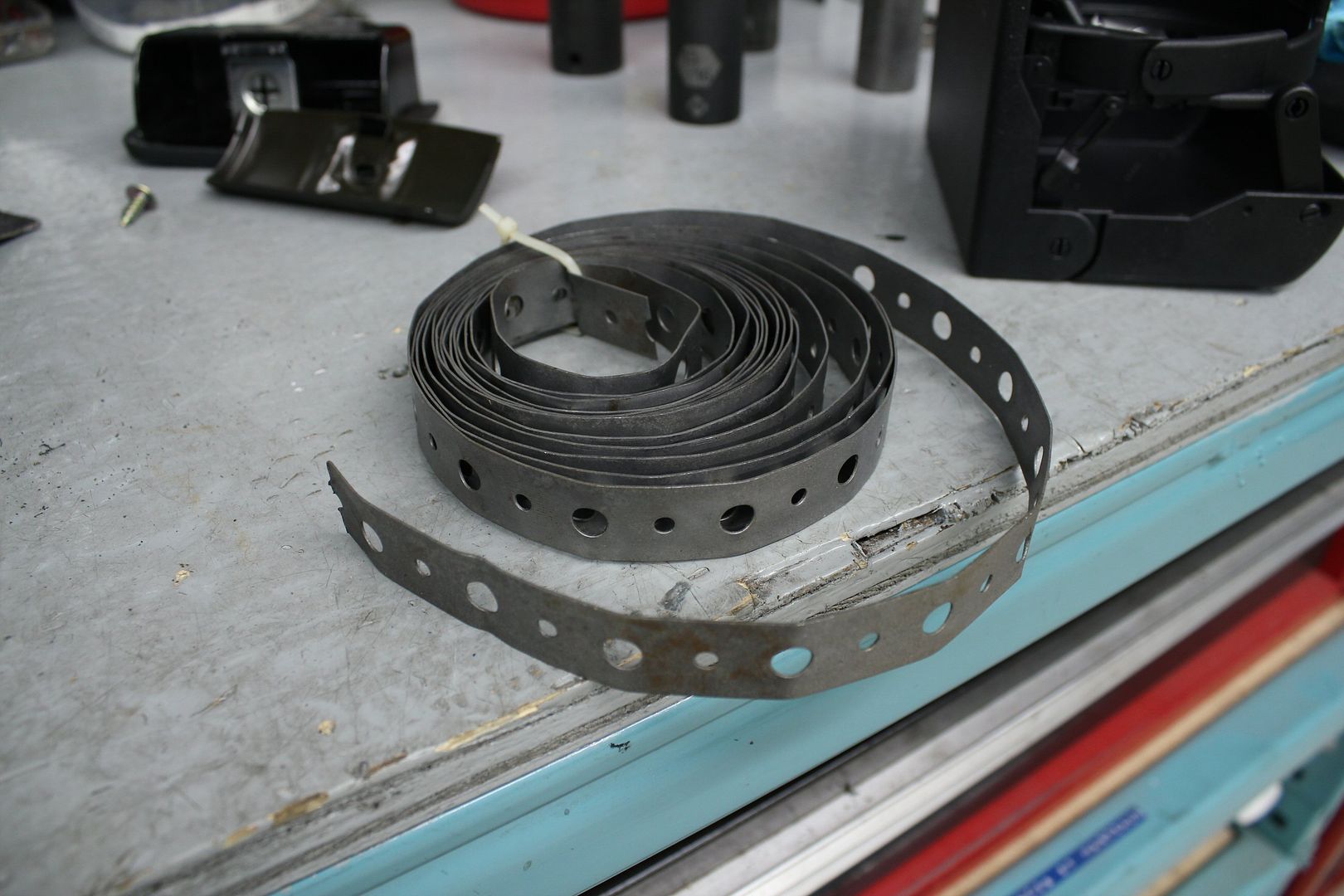

and this is what i got,

not too bad considering it cost me 30$ in all;

but the day i was supposed to pick it up, he still hadn't made it,

he told me to go get something to eat (i was after closing time and he was alone in the shop),

and it would be done when i came back, but i was pissed because he asked me again the length of the bar,

in a hurry i think i told him the wrong length,

anyway, when i came back a full hour later it still wasn't done because other people had came by,

when i pressed him to finish he was drilling the holes, and i told him i'd take care of it,

but they were mostly done, at the dimension i told him;

if finished them with my trusty press drill;

using a pneumatic sander, i smoothed it all to death;

took off about 1/2 a pound of metal in total (with the holes)

while the main hoop was in, i placed the other 2 pieces of the cage pretty much where they would go,

and attempted to fit the cross brace;

but obviously i didn't, since the length i told the fabricator in a hurry was 42" not 43....

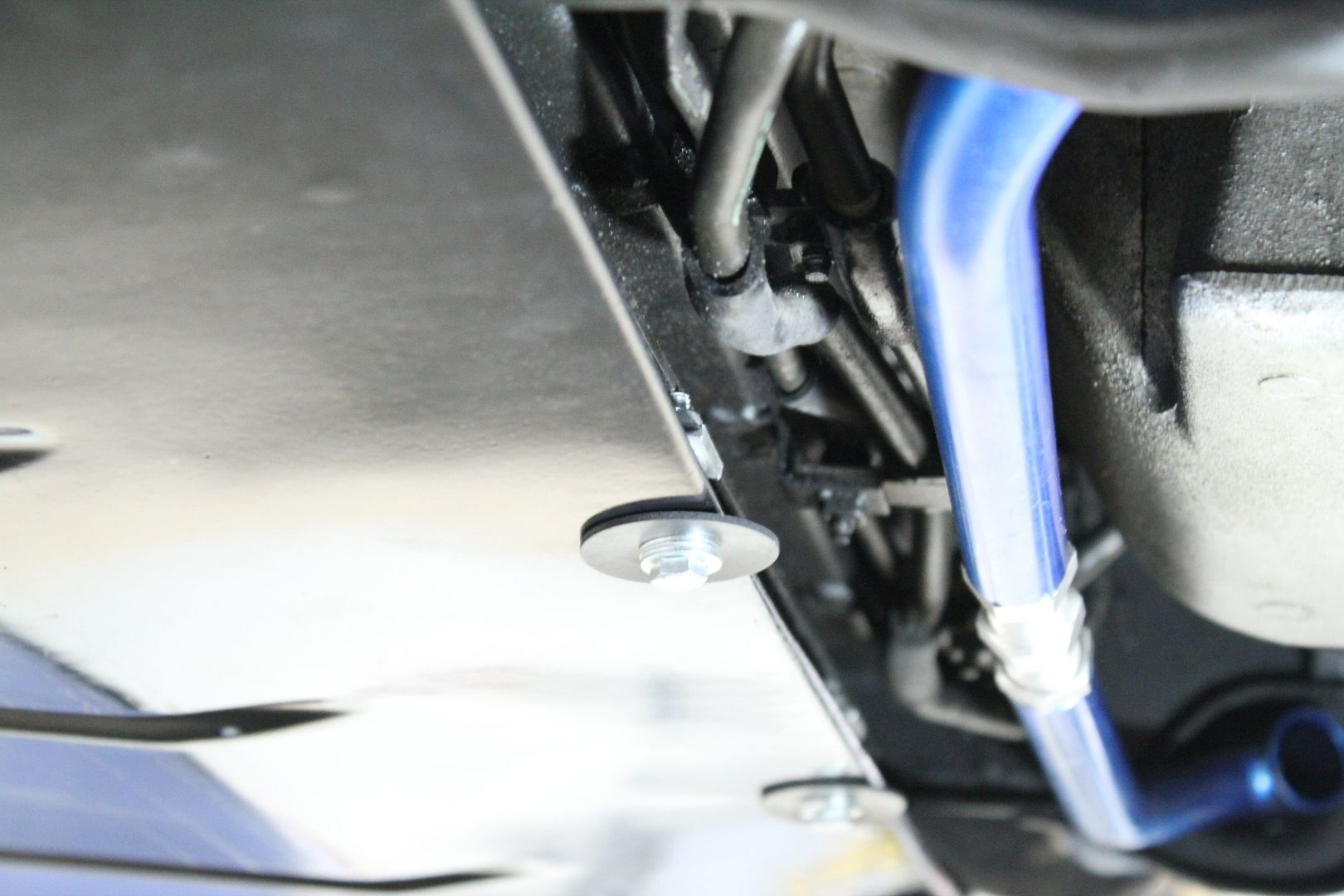

the next day my dad offered to bring it to the shop next to our house to get it fixed and also have the brackets modified on the cage

i had longer brackets welded more towards the back, and also added one on the passenger side...

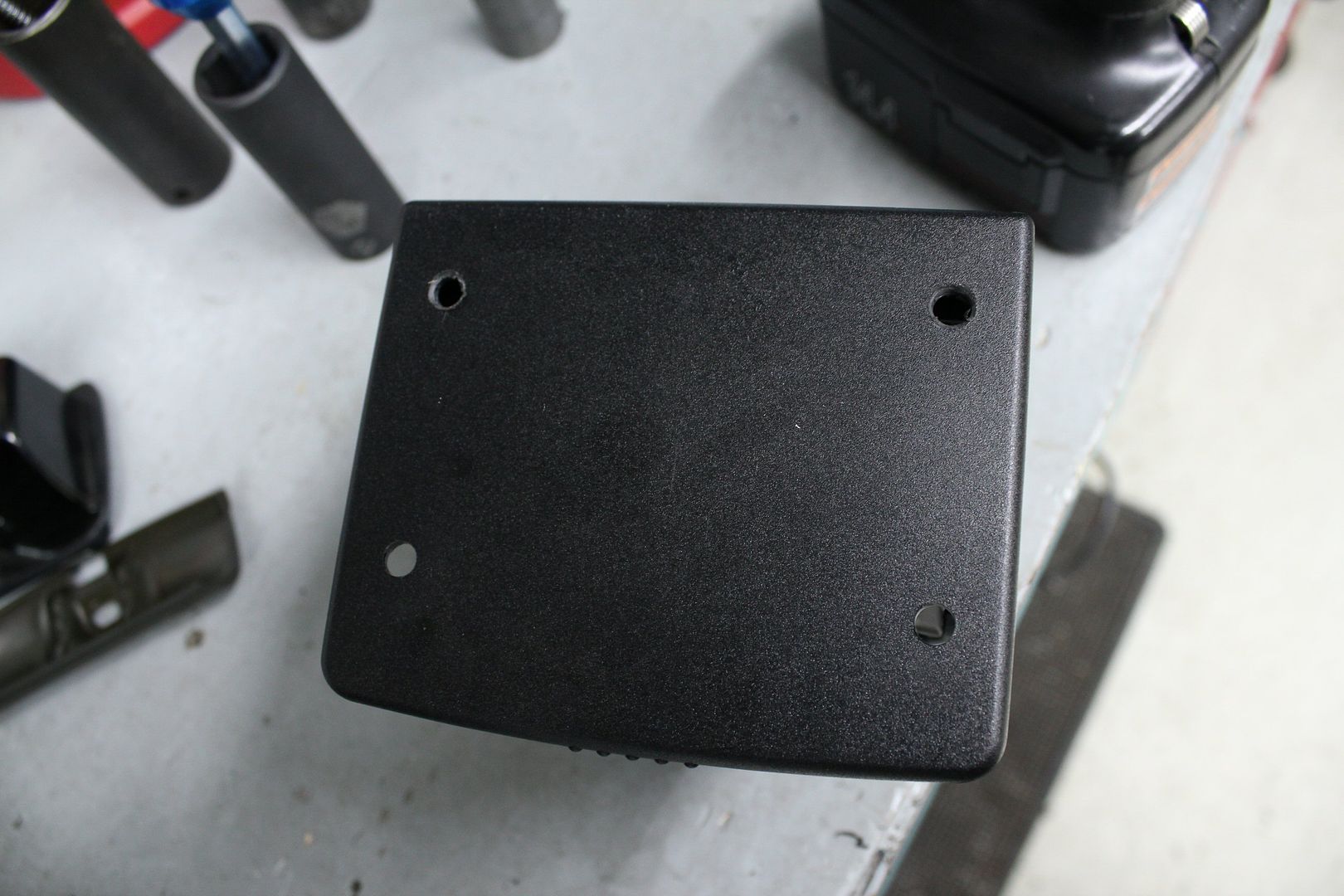

to go with this,

a full width harness bar that would be much stronger;

the cross brace only had a bit added onto it to make it 43" long

i firmly attached the cage upright to be able to work on it without it falling on the car;

i drilled some holes in the brackets (not fun drilling something that isn't rigidly fixed onto something, it vibrates..)

then i placed the bar where it would go, marked some spots with a sharpie and drilled them on the press drill

more about the cage in the week5 update....

but its not over for week4, keep reading -->

Leave a comment: