Originally posted by M13

View Post

Announcement

Collapse

No announcement yet.

REIMAX (Collar clearances, pics)

Collapse

X

-

Some more info would help this soon the be sticky: diameter (flat spot to flat spot) of inner gear on Tomei, HKS, JUN etc. oil pumps...

and maybe the diameter of the collar its self.

Went to see how those pumps work (eccentric oil pump) Simple!Last edited by GTRADDICT; 03-02-2011, 09:41 PM.03 lancer dead

68 gmc w/355 cid rice killer

05 chevy silverado L33

2010 crv Wife's ride

1987 Harley Softail custom

Comment

-

So here is another update withe the measurments of my ~R33 crank! They are not looking very good!

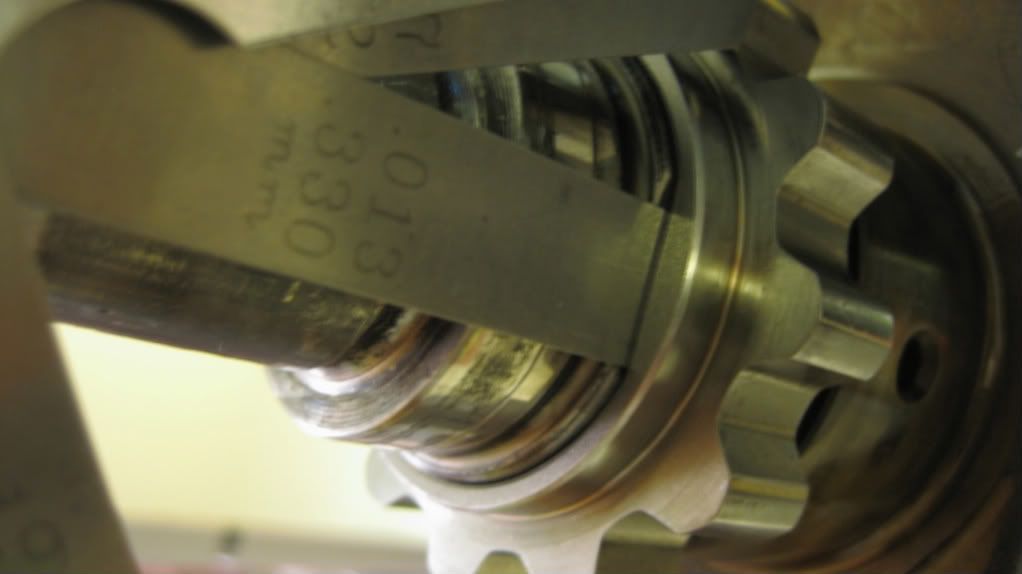

Firs is stock pump gear! .014 and .013 comes to an average ~ .006" on each side - even more than with australian collar! THIS IS CRAZY

Now with Reimax gears - .019 and .018 SO - ~.009 each side! No matter what metal this would be made of they will brake soon or later with this wobble!

In the end i would like to state my opinion, because i see sometimes people are saying that there should be a clearance, if Nissan engeneers did it so there should be one! I would like to say that Nissan almost missed the oil pump with theirs early short oil pump drives, and in the "upgraded" drive they only bend aid this problem extending the drive, so no they didn't pay enough atention in that area and the clearances there should be much smaller than what we experiencing right here!

TTBB is a true ACN member

TTBB is a true ACN member

Comment

-

can you measure the diameter of the R33 crank flat to flat?

I wish I had measured my R34 crank then we could have compared! we just need someone to measure a new R34 crank then,

the other possibility is that usually when one metal is softer than another, the hard one, even though only marginally harder, (even different grades of hardened steel) will still deform the softer metal, so if the oil pump gear is harder than the crank itself, it makes sense that these old cranks you measure here are soo much larger clearance wise, because they've been deformed from the original perfect shape!

its just a theory, all that to say we really need someone with a brand new R34 crank and oil pump (oem/N1) to measure those clearances, that would be key!

then we could conclude wether its a nissan engineering fault, or if its just wear on the materials.

EDIT: Actually, looking at the photo you just posted, its 100% obvious that the crankshaft must be made of a softer steel than the oil pump gears! so I would say that truthfully the clearance you are measuring is so bad because thats all used stuff...

we deffinitely need to see what a new crank compares like.Last edited by archaeic_bloke; 03-04-2011, 05:42 PM.The SkyLife Community & News Website --> http://www.skylife4ever.com

Comment

-

I have to disagree with you here! Even though all of this stuff is used, i clearly do not see anything wrong with it!Originally posted by archaeic_bloke View Postcan you measure the diameter of the R33 crank flat to flat?

I wish I had measured my R34 crank then we could have compared! we just need someone to measure a new R34 crank then,

the other possibility is that usually when one metal is softer than another, the hard one, even though only marginally harder, (even different grades of hardened steel) will still deform the softer metal, so if the oil pump gear is harder than the crank itself, it makes sense that these old cranks you measure here are soo much larger clearance wise, because they've been deformed from the original perfect shape!

its just a theory, all that to say we really need someone with a brand new R34 crank and oil pump (oem/N1) to measure those clearances, that would be key!

then we could conclude wether its a nissan engineering fault, or if its just wear on the materials.

EDIT: Actually, looking at the photo you just posted, its 100% obvious that the crankshaft must be made of a softer steel than the oil pump gears! so I would say that truthfully the clearance you are measuring is so bad because thats all used stuff...

we deffinitely need to see what a new crank compares like.

Look at the last picture in the post 18, you clearly see that there is no warpage or some kind of phusical distortion of that perticular oil pump drive, except where the oil pump was hitting. Why was it hitting there?? - Too much wobble since beginning!!!

Post 14, second picture from the end. 90% of the oil pump area ( under the red line) is never even been attached to the crank, which means - brand new condition! Unless you want to phusically or even theoretically prove that that perticular oil pump gear is worn in any whay, in that area!!!!

I can probably use a paint to express myself better on the pictures, since ESL to me! But I strongly belive that someone is understanding me clearly and can chim in!Last edited by tryingtobebest; 03-04-2011, 06:14 PM.TTBB is a true ACN member

Comment

-

so after all of this research and these conclusions you are saying there is no point in buying a r33/34 crank and best option is a r32 crank with allens collars if using a oem or n1 pump? correct me if i am wrong.1991 Nissan Skyline R32 GT-R: 710whp 521 ft/lbs 27.5psi 11.8 @126mph low boost

Comment

-

Im sorry,would i be intrested in macining NEW REIMAX GEARS?? - NO; Would i be intrested in Allens collars for reimax gears - Yes. But i think his price for limited collars for Reimax gears would be too high, if he ever do them! In my opinion this is simple task and that shouldn cost any more expensive, unless i repeat unless, your machine or jig is strictly set on producing only stock size collars, and not used for anything else!Originally posted by vaderj View PostI'm in calgary aswell, would you be interested in splitting the cost of getting a few reimax inner gears machined with the proper id to match the long snout crank?

In short words - YES. Because paying... ???, how much did you payed for the new crank? I wouldnt afford! And if you are buying second hand r33 crank you have really good chance to end up with large clearances!Originally posted by gtrjon View Postso after all of this research and these conclusions you are saying there is no point in buying a r33/34 crank and best option is a r32 crank with allens collars if using a oem or n1 pump? correct me if i am wrong.

Besides there is a bunch of other places that sells collars, for example yesterday i found a new ( to me) website "raw brokerage" they sell collars as well, i never tried them but they still might be good (clearancevise). The only 3 ive tried were: Jun, Australian, and Allen, where i found out Allens one being extremelly properly done, with the right tolerances!

My plan is to use this 60k km oil pump with Allen collar, and if hi will not going to agree in prodicing the Reimax spec collars ill probably try to return it back to Reimax through the Feastauto, where i got it from! Because this is BS, i paid $450 for this gearset and it is not even the same as stock/n1 diameter gears!Last edited by tryingtobebest; 03-04-2011, 06:44 PM.TTBB is a true ACN member

Comment

-

That's what I was saying a couple of reply's ago...Originally posted by gtrjon View Postso after all of this research and these conclusions you are saying there is no point in buying a r33/34 crank and best option is a r32 crank with allens collars if using a oem or n1 pump? correct me if i am wrong.03 lancer dead

68 gmc w/355 cid rice killer

05 chevy silverado L33

2010 crv Wife's ride

1987 Harley Softail custom

Comment

-

I've got a fixed R32 crank for sale on the FS/WTB forum.. complete with a JDMS13RHD crank collar already installed! Anyone interested should buy it :P1992 GTR - 2.7L, GT2871R's, forged bottom end, big valves, 270* cams, R34 getrag

2000 Honda Insight - 70+mpg daily driver

2003 Sierra 2500HD Diesel - Tow vehicle

Comment

-

What I meant was to machine copies copies of the reimax gearset with a tighter ID for the long snout crank. I don't like the collar idea when you can simply replace the inner gear of the oil pump with a gear that would fit tighter. Especially if we could base these gears on a REimax set and position the drive in a better spot. If not I'll attempt this with an N1 pump and see what kind of results I'd get.

Comment

-

Some people have such a difficult time understanding that this is a clearance issue. It's such a simple concept it's unbelievable to me that some cannot grasp the idea... I was looking at a brand new R33 crank and N1 oil pump the other day that had way to much clearance. The guy who owned them was so hard headed that he is still paying mega bucks to have his RB assembled, even though I explained exactly why this design is destined to fail.

I guess some will waste money and never learn...

Comment

-

yep^^

I've been saying whats been said since 2007. Just look at the posts ive made over the years in other sticky threads in this forum. Its only been since recently that people take note of it. Too bad jun/nissan cant figure this out :S Dont need to be smart to know its just a sloppy design.

to vaderj: Its cheaper to replace a collar that machine a new pump gear. Also, with a collar built, it would suite most pumps (jun, OEM//N1 + more Im sure) So if you wanted to upgrade to a better pump, you could do so. or you can machine a new gear each time like you said.

If you guys have time, take another read at my f/s thread. Ive updated a bit ago with lots of easier to understand info. Its over 2000 words to read :

:

I still think a 2J style drive would be best is you were to even consider making a new custom gear set. Screw this 2 flat drive style. Then, you can use the oem pump, slap in the new 4140 alloy gears with a 2J drive collar. 3 pieces, hopefully cheap enough most us guys can afford it. Its something ive been wanting to do for over 4 years. Id jump right on it but it takes capitol to get it done and I just dont have any. I dont want to jump into it and have to wait a year to get my investment back. if anyone wants to sponsor this, i can get a quote within a week. Have everything drafted a couple weeks after and do a small production to start. Then need people to try em out. If everything works well, do a larger production and then cheap gears and collars for everyone! I already have the plan, just need to pick a pump style and send the info to get a program built for the CNC then go from there.ALLEN PETERSEN

Number (604) 961-2449

4XTOYS/ Lower Mainland Skyline Service and aftermarket RB parts.

RB30`s for sale!

Comment

Comment