...Sr20's are reknowned for blowing up though...lol but i would guess that this you'd be talking about a built SR20... ?

I'd have to agree that A/M parts are far more readily available for SR's than RB20's... but the RB is an RB soooo...lol

I'd have to agree that A/M parts are far more readily available for SR's than RB20's... but the RB is an RB soooo...lol

How well do you know your boxes??

How well do you know your boxes??

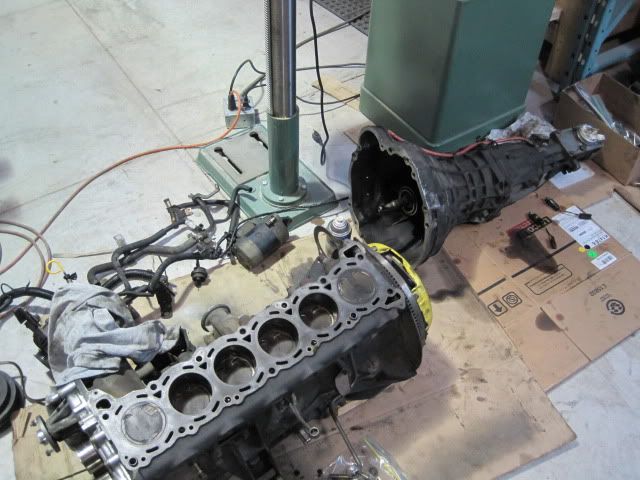

Will certainly take you up on it next winter when i do the 23! I cleaned the block with degreaser, and the water galleries with the same as well as brake clean etc, then rinsed them out with water.. Just need to clean the outside which is drenched in degreaser at the moment then give'r a paint!

Will certainly take you up on it next winter when i do the 23! I cleaned the block with degreaser, and the water galleries with the same as well as brake clean etc, then rinsed them out with water.. Just need to clean the outside which is drenched in degreaser at the moment then give'r a paint!

Comment