Chapter 23 - Almost there, week12-13, part2

------------------------------

Day 43

Like everyday other day, when I start working on the car for the evening, I try to think about what I could have forgotten to do,

Then I remember, the upper control arms…

A couple weeks ago, Josh (archaeic bloke) finshed work on his car (for now..) and after driving it around for a bit, he could hear a clunking noise coming from the front upper control arms,

Turns out those arms being adjustable, with bearings, can’t be torqued as much as the OEM ones, because the bearings aren’t designed for axial load

While hes got AMS parts, I have the exact same design from KTS, so I had the same problem

And I talked to Haig@autoworx way back In January about this when I bought the arms

Where Josh put red lock-tite and got the bolt just over finger tight, Haig told me to get them finger tight as well, but then lock them in place with a second nut

Pretty straight forward, you first tighten the bolt/nut till the arm isn’t loose anymore, then you put the 2nd nut and tighten both nuts together

After that I took out my Apex’i power intake kit with the freshly powder coated elbows and tried to assemble it

The paper gaskets were to big, so I cut about 1,5mm off the edge

And I say tried, because after downloading the pdf instructions from apexi’s website, I saw that I was missing one of the 4 brackets, and that the remaining 3 had been bent out of their original shape

I bought the kit “new” only used for a couple dyno pulls

Whatever, I paid about ˝ what its worth, so its all good

So I left it like that, and bent the brackets back into shape, didn’t bolt anything down before I get the headlights back in

At the beginning of the week, I called Tuboquip again about the AN-10 45deg fitting that I had been waiting for for 7 weeks,

The last time I called (a week prior) I was told that they got the fitting and the line would be assembled and shipped the same day, but I never got it after 5 days

So when I called, I got the customer service guy, and I was very serious with him, he told hed check and call me back,

He called me after 5 minutes, apparently the fitting had been sittting under the counter for a week, I would have it the next morning, FINALLY

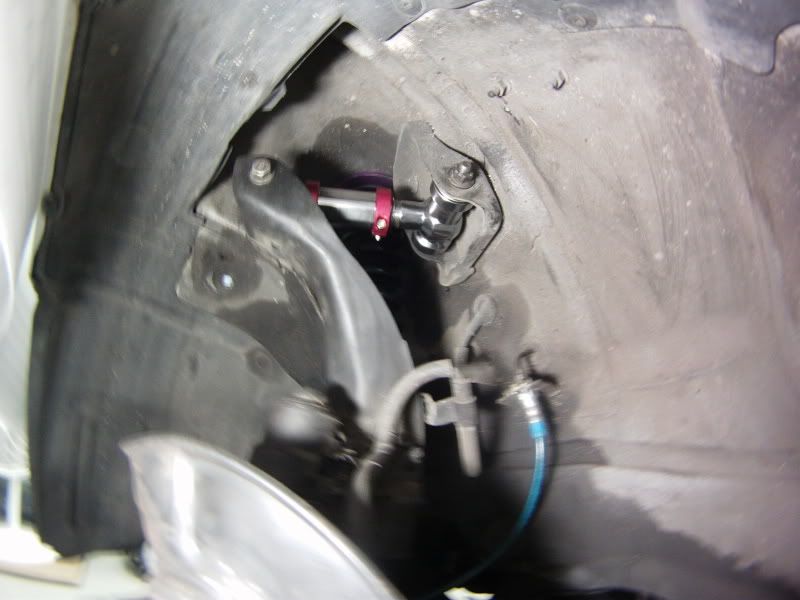

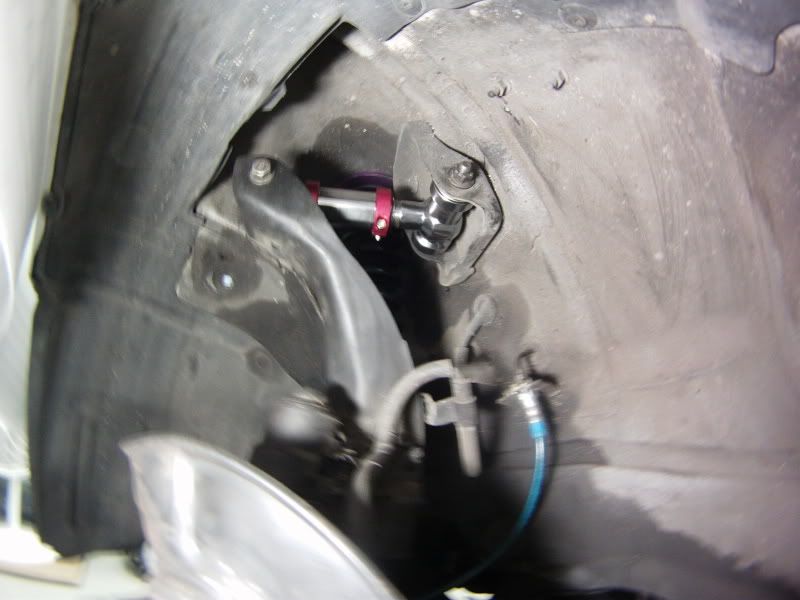

So I finally screwed it into

Because of the angle of the line, and the fact that its pretty stiff, I had to cut a much bigger hole in the plastic fender liner to have it go through

And then connected the original lines going to the filter plate

When I originally measured the length of the extensions, I put a piece of tape on each of the old lines to indicate which went with which line afterwards

As you can see, the lines are obviously not the same at all,

At that moment I went WTF, WTF ! did I measure wrong ?

After calming down, I swapped the lines, and it was pretty much the same length, oufff

I must have labelled them wrong

And talking about parts that look a-hell-of-a-long-time to arrive,

The darn upper intercooler bushings, I was only missing 1 but ordered 2 just in case

Got them straight from Nissan, which came from Japan, it took 6 weeks

At first I was scared it was the worng part number, because it was really hard to understand the nissan schematics

Perfecto !

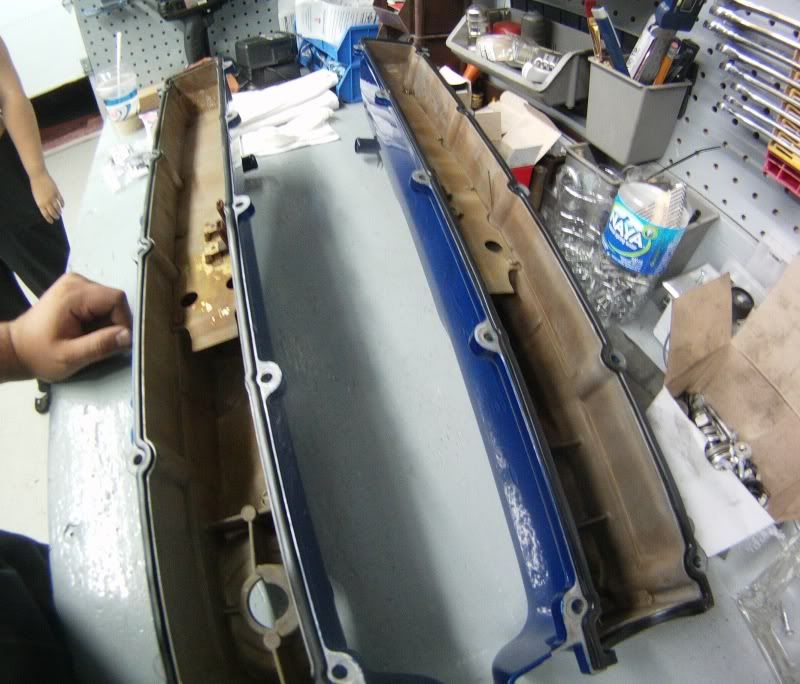

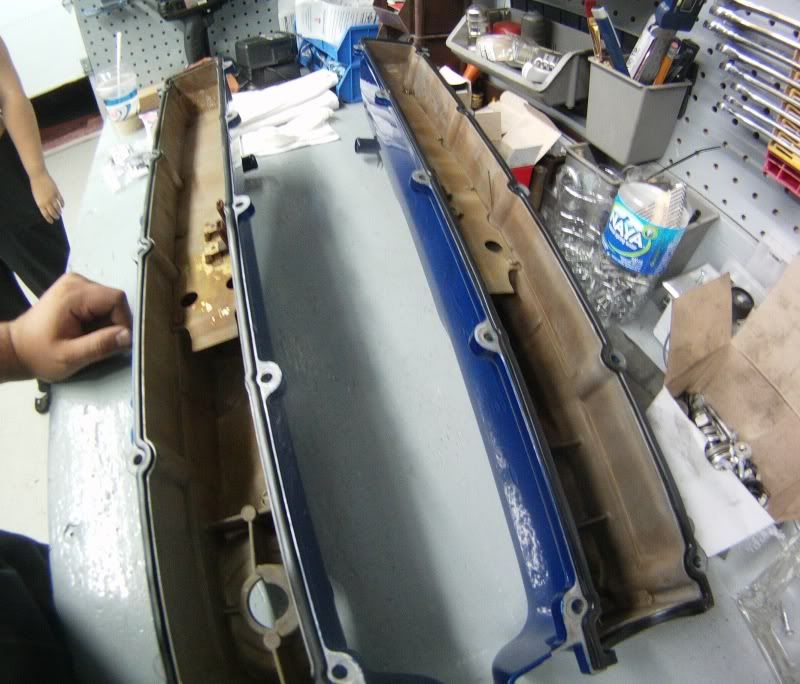

Then I cleaned the surfaces were the valve cover gasket went,

There was a lot of silicone leftovers

I carefully scrapped it off with a razor blade, and finished it with soft steel wool

Then fitted the gasket in the valve covers, I re-used the old ones which were still like new

And re-assembly of the valve covers began

Put some new silicone gasket

I thightened all the screws in a cross pattern, just like you would with wheel nuts

When I was putting the screws in place, before tightening them, I accidently dropped one of the screws’ grommet under the intake manifold, fuuuuu

Filled the splitfire coilpacks full of jizz / dielectic grease

And screwed them into place

Hmm blue on blue, Greddy cap FTW

Then stuck the R34 satin black ormament plate on the coil cover

Yeah, that’s what it finally looks like, cover with 6 slots, baller

Put when the paint shop acid dipped the cover, they melted the rubber seal, so it was a bit hard to put exactly in place, again a cross bolting pattern did the trick

After that I put the cam gear cover on, just to see how it would look and added the flat black painted CAS

Then I tried the rear turbo pipe Vibrant coupler I bought from Ben@JNS

Which ended up not looking too swell

So the OEM coupler went back on, with the Vibrant T-bolt clamps

Then I couldn’t remember how to get the HKS top hot hardpipe on and it was uber late so I stopped there and went to bed

/day43

------------------------------

Day 43

Like everyday other day, when I start working on the car for the evening, I try to think about what I could have forgotten to do,

Then I remember, the upper control arms…

A couple weeks ago, Josh (archaeic bloke) finshed work on his car (for now..) and after driving it around for a bit, he could hear a clunking noise coming from the front upper control arms,

Turns out those arms being adjustable, with bearings, can’t be torqued as much as the OEM ones, because the bearings aren’t designed for axial load

While hes got AMS parts, I have the exact same design from KTS, so I had the same problem

And I talked to Haig@autoworx way back In January about this when I bought the arms

Where Josh put red lock-tite and got the bolt just over finger tight, Haig told me to get them finger tight as well, but then lock them in place with a second nut

Pretty straight forward, you first tighten the bolt/nut till the arm isn’t loose anymore, then you put the 2nd nut and tighten both nuts together

After that I took out my Apex’i power intake kit with the freshly powder coated elbows and tried to assemble it

The paper gaskets were to big, so I cut about 1,5mm off the edge

And I say tried, because after downloading the pdf instructions from apexi’s website, I saw that I was missing one of the 4 brackets, and that the remaining 3 had been bent out of their original shape

I bought the kit “new” only used for a couple dyno pulls

Whatever, I paid about ˝ what its worth, so its all good

So I left it like that, and bent the brackets back into shape, didn’t bolt anything down before I get the headlights back in

At the beginning of the week, I called Tuboquip again about the AN-10 45deg fitting that I had been waiting for for 7 weeks,

The last time I called (a week prior) I was told that they got the fitting and the line would be assembled and shipped the same day, but I never got it after 5 days

So when I called, I got the customer service guy, and I was very serious with him, he told hed check and call me back,

He called me after 5 minutes, apparently the fitting had been sittting under the counter for a week, I would have it the next morning, FINALLY

So I finally screwed it into

Because of the angle of the line, and the fact that its pretty stiff, I had to cut a much bigger hole in the plastic fender liner to have it go through

And then connected the original lines going to the filter plate

When I originally measured the length of the extensions, I put a piece of tape on each of the old lines to indicate which went with which line afterwards

As you can see, the lines are obviously not the same at all,

At that moment I went WTF, WTF ! did I measure wrong ?

After calming down, I swapped the lines, and it was pretty much the same length, oufff

I must have labelled them wrong

And talking about parts that look a-hell-of-a-long-time to arrive,

The darn upper intercooler bushings, I was only missing 1 but ordered 2 just in case

Got them straight from Nissan, which came from Japan, it took 6 weeks

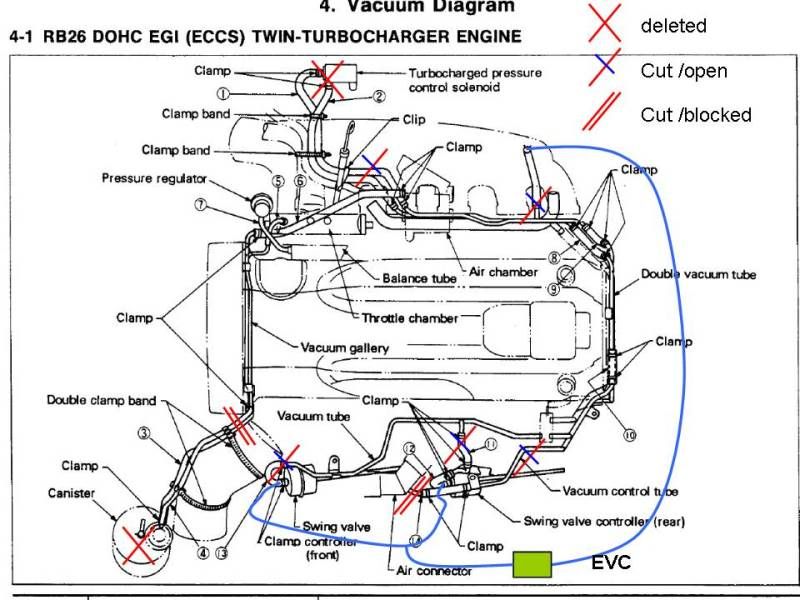

At first I was scared it was the worng part number, because it was really hard to understand the nissan schematics

Perfecto !

Then I cleaned the surfaces were the valve cover gasket went,

There was a lot of silicone leftovers

I carefully scrapped it off with a razor blade, and finished it with soft steel wool

Then fitted the gasket in the valve covers, I re-used the old ones which were still like new

And re-assembly of the valve covers began

Put some new silicone gasket

I thightened all the screws in a cross pattern, just like you would with wheel nuts

When I was putting the screws in place, before tightening them, I accidently dropped one of the screws’ grommet under the intake manifold, fuuuuu

Filled the splitfire coilpacks full of jizz / dielectic grease

And screwed them into place

Hmm blue on blue, Greddy cap FTW

Then stuck the R34 satin black ormament plate on the coil cover

Yeah, that’s what it finally looks like, cover with 6 slots, baller

Put when the paint shop acid dipped the cover, they melted the rubber seal, so it was a bit hard to put exactly in place, again a cross bolting pattern did the trick

After that I put the cam gear cover on, just to see how it would look and added the flat black painted CAS

Then I tried the rear turbo pipe Vibrant coupler I bought from Ben@JNS

Which ended up not looking too swell

So the OEM coupler went back on, with the Vibrant T-bolt clamps

Then I couldn’t remember how to get the HKS top hot hardpipe on and it was uber late so I stopped there and went to bed

/day43

Comment