why are you going with gts rear valances?

Announcement

Collapse

No announcement yet.

Frankiman's street/track GTR project

Collapse

X

-

Ahhh Frank i always look forward to your updates! Great work again keep it coming!1992 BNR32 Skyline GT-R

Ass, grass or cash Nobody Rides for free!!Originally posted by bignateIf you are too lazy to search the site for info you are certainly too lazy maintain a 15+yr old JDM car.

Comment

-

Ohhhh ok, I thought you were removing n1 stuff and putting on type m.Originally posted by frankiman View Postbecause i think the rear isn't balanced, too much body in front, not enough behind it

Also, looks like you dint always have those n1 ducts, those holes in your rebar aren't factory!GTRC-OG

Comment

-

Chapter 14 - Theworkinprogress, week2, part1

---------------

Day 4 and ~5

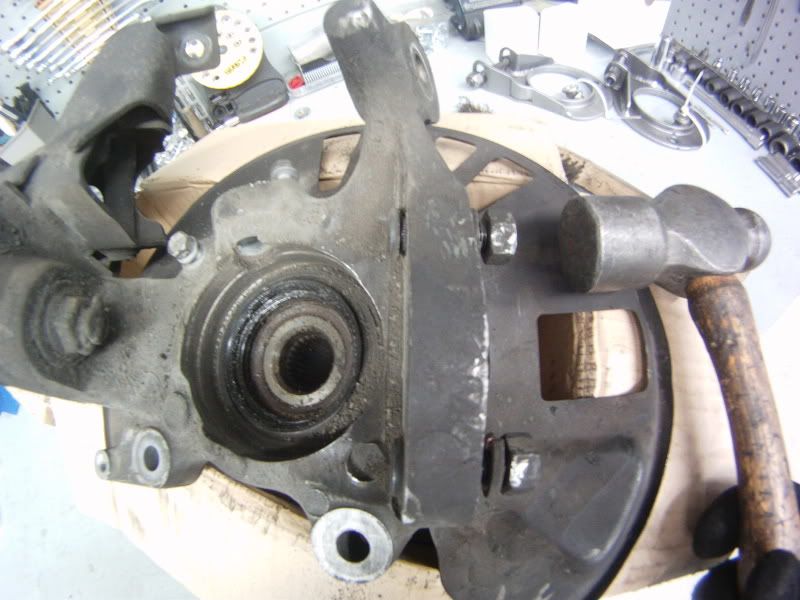

so i started by removing the snapped bolts from the fronts knuckle

step 1, take a bite out of a home made cookie, for motivation

step 2, punch the center of the bolt

step 3, using a small drill bit, drill as deap as possible in the center of the bolt

step 4, using a magnet to clean the shavings is pretty helpfull in keeping your work bench clean

then use bigger and bigger drill bits till your hole is about 1/2 the diameter of the bolt

step 5, choose the largest extractor that fits into the whole, then gently punch it in

step 6, using the right spanner, or vise-grips as i did, then turn counter-clockwise, the extractor will dig into the bolt and it will un-screw out

results, bolt #1

bolt #2

bolt #3 on 2nd knuckle is simply rinse-repeat

end with another bite of cookie to celebrate a job well done

then got brand new bolts to replace the snapped ones

new parts, Moonface front roll center adjuster

japanese-only instructions

then, screw the nut onto the outter ball joint studs, flat to the end of the stud, then punch it out with a heavy metal mechanic's style hammer

punch the other out

new vs old hardware,

then after a scientific comparison, i found out those studs are exactly the same as the wheel studs, and are in perfect condition

how it looks on,

didn't use the extra spacer, since my car won't be hella-flush low-as-fawk style, so it would have been overkill

knuckles now hyper clean

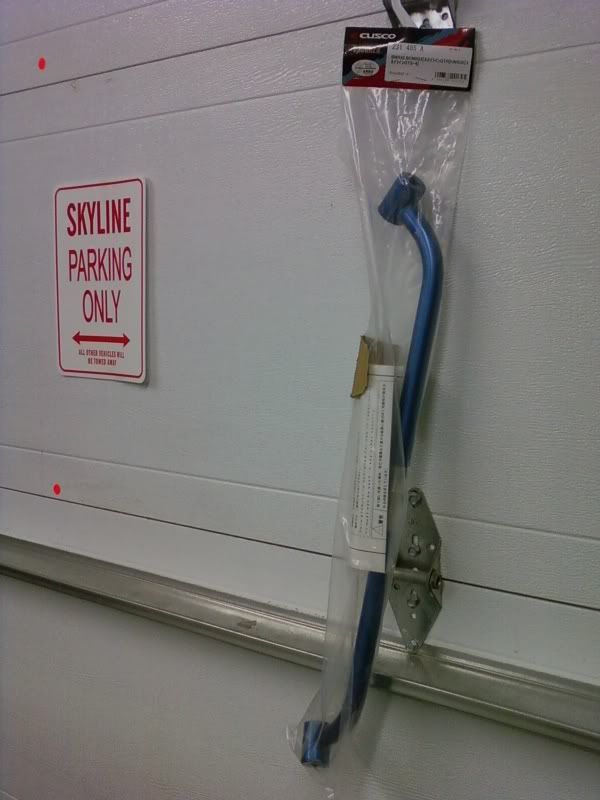

then took out the new Cusco ajustable tension rods

then my Cusco ajustable tension rod pipe

japan-only use, LOLz

and my KTS adjustable front upper control arms, with NSK japanese bearings

and my new Whiteline ajustable front sway bar

this sway bar is the same size as the stock one, but much heavier, because the OEM bar is hollow and the WL bar is full, so much stiffer AND adjustable ends

Moonface use fawking stupid sockets screws that are inaccessible when the front half shaft are fitted into the hubs,

so you have to bolt them without the FUCA attached so you can pull the half-shaft out

and the Cusco tension rods were pretty hard to fit into the subframe brackets, i had to tap them in with a rubber mallet

anyway, everything fitted

and the tension rod pipe is hella tight to fit, i tried to shorten it with the adjustment, but couldn't go all the way, so i took i apart to find some of the threads had a little bit rust inside, greased it all and put it back together and worked fine, then i had to spend 15 munites tighteninig the adjustment part with a wescott wrench, since i didn't have the odd sized wrench for it (21mm i think)

weirdly, i have to slightly drill out the forward holes on both side of the swaybar for the endlinks to go through

-----------------------------

day ~5 and 6

after i found a very small paint chip on my front passenger fender, i went mad, then taped 1/2'' of foam on it to protect it, since its so close to my work bench

then, i did another Seafoam treatment, since i didn't do it the exact right way the first time

[YOUTUBE]<object width="480" height="385"><param name="movie" value="http://www.youtube.com/v/L0ThVPSE0To&hl=en_US&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/L0ThVPSE0To&hl=en_US&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="480" height="385"></embed></object>[/YOUTUBE]

then i went to my dad;

me; ''would you like to participate to my ''save the hammers'' foundation?''

dad; ''wtf is that?''

me; ''its a group buy on tie rod puller, so i can stop hammer the fawk out of them''

dad; ''how is it a group buy?''

me; ''well as a group, you give me money and i go to the store to buy the tools''

dad; ''.......sure''

its pretty much the only tools we didn't have

started working on the rear suspension

first, took off my Cusco rear strut tower bar

no-mo' handbrake

then everything off on driver side

super dirty wheel bearings, crusted grease

then, i remembered Josh's build, where he cleaned alot of stuff around the fuel filler neck, so i did the same

holy shiit!

i took most of the stuff off with a brush, alot of stuff

------------------------------------

day 7

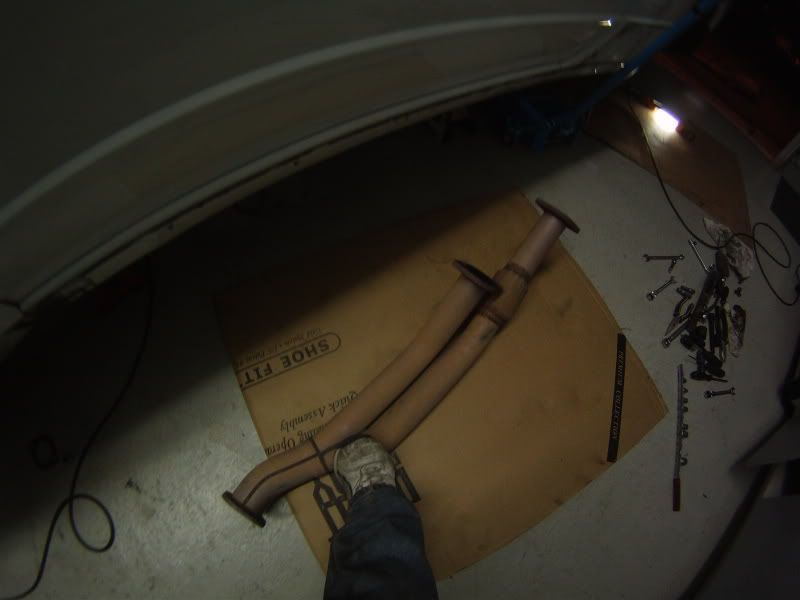

while listening the to Habs VS Penguins game#4, i got into taking the whole exhaust system out, by myself, with very little room under the car

i took me all evening almost

started by removing the dump-pipe to down-pipe nuts, with a super long exention and a u-joint, it was a real PITA, mostly because the car was only 18inches off the ground and well... i'm built like a football player, i couldn't sit on my side, so i had to work with only 1 hand

then i loosen all the hangars and kept the exhaust in place with a jack

then i snapped a bolt (yeah again) joining the downpipe to the cat, because i couldn't get the cat's hanger/bracket out of where it was, so i couldn't take the downpipe out on its own anymore

so i slowly descended the cat-back with the jack and suddently the downpipe just fell out

then opened the garage door and slid the cat-back outside

pure win @ 11pm

empty space

and capped of the day by removing the rear sway bar

at the end of day 7, bunch of stuff

Comment

-

Chapter 14 - Theworkinprogress, week2, part2

-----------------------------

day 8

spent most of day 8 dropping off stuff at shops;

on day 7 i went to Autoworx with a friend to drop off his Z32 for an inspection, dropped off my test pipe to have a wideband sensor bung welded

then picked it up the next morning, and test-fitted my new wideband sensor

Turboquip, i spent over an hour to design my new custom brake lines with their catalog, and they fawking don't have 90deg m10x1 fittings, so i had to go with a bunch of adapters and stuff... anyway, will be covered next week (as i am picking them up tomorrow, from the time i'm writing this)

Selex Suspension, where i dropped off my HKS coilovers for a reconditionning and dyno test

picked up some more new grade8 bolts washers and nuts at Quebec Bolt industries

---------------------

then went back to work on the car for a bit

got my new Whiteline adjustable rear sway bar, and my god thats alot of hardware, as the kit comes with its own endlinks

greased up the bushings with the provided grease pack, and bolted it in place

and found it came very very close to the rear diff's yoke

then i removed the catalyser from the exhaust, to find it had an interesting color insisde, on the intake side

then tried to cut the snapped bolt to get it off the cat

started with a metal hand saw, didn't quite work

then put it in a vice, to try to un-screw just the nut, ended up stripping the nut as it was jammed hard

fawk that, power tools, i took out my air powered disc cutter

don't forget to wear eye protection kids

there we go... results

win

so thats that... end of week 2

alot of work was done, still much more to go, i got 6 weeks left to finish this build and get the car tuned

Comment

-

Frank i wish you lived in Ontario man! hahah so feel free to move to TO would love to be there during all of this epicness!!! keep it commin!1992 BNR32 Skyline GT-R

Ass, grass or cash Nobody Rides for free!!Originally posted by bignateIf you are too lazy to search the site for info you are certainly too lazy maintain a 15+yr old JDM car.

Comment

haha

haha

Comment