what/where is the shop that resurfaced your flywheel?

Announcement

Collapse

No announcement yet.

mitch32 rebuild/winter project

Collapse

X

-

Mitch, that is AWESOME.. thats exactly what i was looking for too, i want to get a little bit more experience with motors so when the time comes... ill prolly end up doing what you did here... thats so awesome,

it really is the best of both worlds... you get to assemble it, but its already had all the super tricky stuff done... i love that... good call.The SkyLife Community & News Website --> http://www.skylife4ever.com

Comment

-

If you don't do it that way then you will have to find custom bearings or fit random sizes to make it work. It'll end up costing you alot more. Even if you brought the engine to a place to machine it they will most likely ask you for rods, new bearings and crankshaft (and old bearings) so they can see if you need a line bore and what they need to machine inorder to make the bearing clearance clear properly. You can't do everything unless you have the million dollars and up in machinary that the machine shops have.Originally posted by archaeic_bloke View PostMitch, that is AWESOME.. thats exactly what i was looking for too, i want to get a little bit more experience with motors so when the time comes... ill prolly end up doing what you did here... thats so awesome,

it really is the best of both worlds... you get to assemble it, but its already had all the super tricky stuff done... i love that... good call.

Comment

-

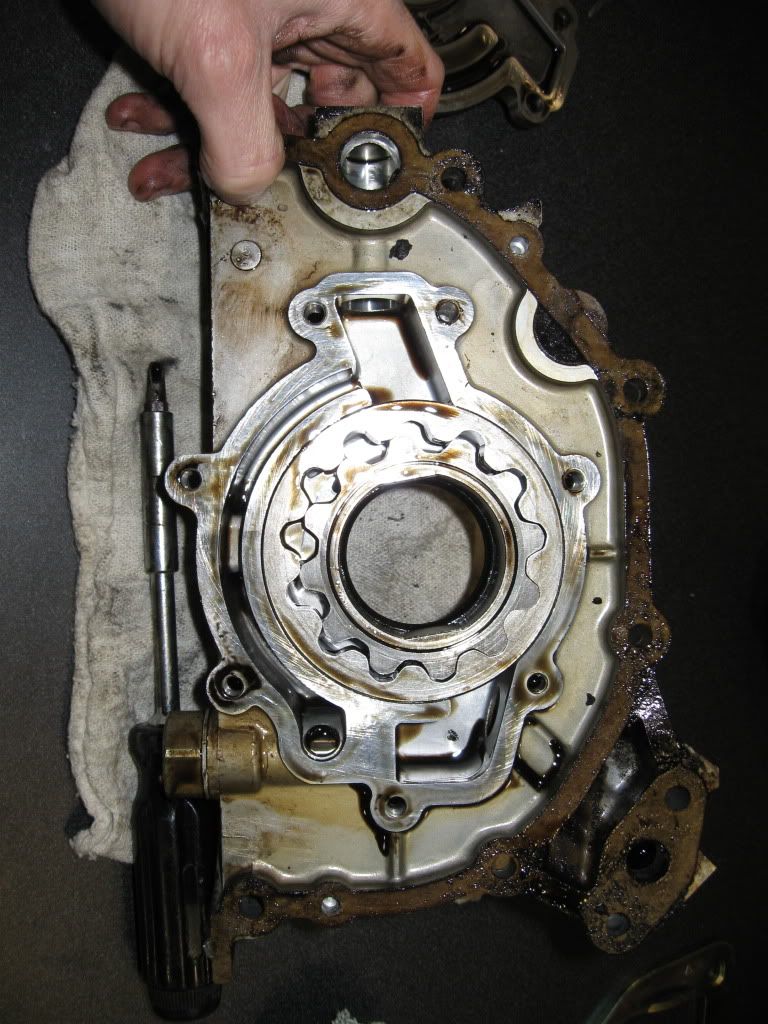

Decided to take apart my old oil pump after work today. Its the OEM, probably the original pump. Even with the low oil pressure, the gears are still in good shape. Some of the bolts to take off the backplate were very easy to remove while others were extremely difficult to remove with a screwdriver. You can see in the pictures that theres very little that drives the pump. Enjoy!

Comment

-

Nice box o parts! An accurate micrometer and bore gauge go a long way. Just measure, pick the clearance you want, and choose graded bearings accordingly. You either pick your bearings to fit your engine or your engine to fit your bearings. I Don't see how sizing your short block to the bearings is cheaper . Build is looking slick though. Are they using a torque plate?

. Build is looking slick though. Are they using a torque plate?

Comment

-

It's probably not cheaper, just easier for me. This way you can order the bearings and the machinist will make the clearances based on the bearings. My machinist is using micrometers and bore gauges, he doesn't use plastic gauge. Basically the theory behind it is that plastic gauge won't be able to show if something is oval. If you plasti-gauge on side on the diameter the other side might have more or less clearance. Yea to the best of my knowledge he's using a torque plate.Originally posted by Ben @ JNS ImportsNice box o parts! An accurate micrometer and bore gauge go a long way. Just measure, pick the clearance you want, and choose graded bearings accordingly. You either pick your bearings to fit your engine or your engine to fit your bearings. I Don't see how sizing your short block to the bearings is cheaper . Build is looking slick though. Are they using a torque plate?

. Build is looking slick though. Are they using a torque plate?

Still not sure if I'm porting the head or not.

Comment

-

Yea, I would of just replaced the oil pump but cylinder 3 had a line on it. It wasn't deep, only like 5 thou but I figured I would have to build at some point. Now I will hopefully have a fully built motor that will be good enough for endurance racing (although it will never see more then 30 min straight of lapping). I went out of my way on everything on this build so far. The current setup will be around 500whp but the motor is built, I feel my weakest link is the Nismo Oil Pump (not an N1, a real Nismo Pump!). Honestly the motor should have no problem with a bigger turbo making even 900whp. I also bought some other stuff for the chassis and brakes. I hope the car is done soon, this summer should be nice!

Comment

-

hehe, only cause your a better driver maybe.Originally posted by frankiman View Posti'm going to love lapping with you, i'll pass you in the corners, and you'll pass me on the straights

My car handles good (the geometry is good, I'll play around with it during the summer and see what happens). All I really need now is some tension rods, and a HICAS lock-bar.

Are you doing a roll-cage?

Comment

-

you should add you setup to these when your done

http://forums.gtrcanada.com/showthread.php?t=49559

as for the hicas, i went all and got autoworx to remove to whole thing, and mod the ps pump, its a ~430$ job

i wont be doing a full cage, but theres a good chance i went do the following, if i get the right guys to help me

http://forums.gtrcanada.com/showthre...367#post476367

and a car that handles good on the streets and one that handles good on the car is totally different;

you never drive to the limit going aroung street corners now do ya..

Comment

-

430$ did that include parts and labor?Originally posted by frankiman View Postyou should add you setup to these when your done

http://forums.gtrcanada.com/showthread.php?t=49559

as for the hicas, i went all and got autoworx to remove to whole thing, and mod the ps pump, its a ~430$ job

i wont be doing a full cage, but theres a good chance i went do the following, if i get the right guys to help me

http://forums.gtrcanada.com/showthre...367#post476367

and a car that handles good on the streets and one that handles good on the car is totally different;

you never drive to the limit going aroung street corners now do ya..

That cage looks cool. Personally I would do a half cage if anything, but I understand wanting to sit 3 people. Usually you make a cage for safety and to stiffen the chassis, some do it for those reasons and to add weight to the back of the car to give a different weight distribution. That design you have might affect handling since the car will be stiff on one side and not the other (not sure if the affect would be noticable). Also that cage is unsafe for the passengers since the car will want to crumple more on the least stiff parts of the car. I personally would not do that cage. If you want it so that you can run a seat harness, you can do it other ways. One way is to remove half the rear seats (so you can have 3 people), put a welded bar over the rear strut towers and run the restraint that way, just make sure the angle is good. You may also need to cut some of the interior.

Comment

Comment